Polyurethane Insulation Foam Material for Discontinuous Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

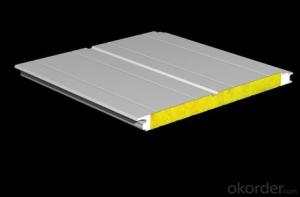

Rigid Blend Polyols for Discontinuous sandwich panels

Rigid Blend Polyol for Discontinuous sandwich panel DBC-402B

Product Introduction

DBC402B blend polyols is a compound which consists of polyether polyols, surfactants, catalysts, foaming agent and flame retardant in a special ratio. The foam has good thermal insulation property, light in weight, high compression strength and flame retardance and other advantages. It is widely used to produce sandwich plates, corrugated plates etc, which applies to make cold stores, cabinets, portable shelters and so on.

Physical Property

Appearance Hydroxyl value mgKOH/g Dynamic viscosity (25°C) mPa.S Density (20°C) g/ml Storage temperature °C Storage stability month | Light yellow transparent viscous liquid 320-400 250-350 1.10-1.16 10-25 6 |

Recommended Ratio

Raw materials | pbw |

DBC-402B blend polyols Isocyanate | 100 100-105 |

Technology and Reactivity(the exact value varies depending on processing conditions)

items | Manual mixing | High temperature machine |

Raw material temperature °C Moulding temperature °C Cream time s Gel time s Free density kg/m3 | 20-25 35-45 30-50 120-200 23-26 | 20-25 35-45 20-30 70-150 23-26 |

Foam Performance

Moulding density Closed-cell rate Thermal conductivity(15°C) Compression strength(perpendicular to the direction of rising) Dimensional stability 24h -20°C 24h 100°C Flame retardant grade | GB 6343 GB 10799 GB 3399 GB/T 8813

GB/T 8811

GB/T8624 | ≥38kg/m3 ≥90% ≤22mW/(m.K) ≥140kPa

≤1% ≤1.5% Level B2 |

FAQ:

1,Could we change the panel size?

Yes, we can product according to your requirement.

2, What is Minumum Production per day?

4000m2 per day x 8 hours.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Extrusion board is different from the foam board, bulk density can not be arbitrarily changed, the technical units to do relatively light But not less than 30kg / cubic meter is generally 35kg / m3 or so manufacturers and manufacturers different

- Q: What is the difference between the board and the core board? The The

- 024 (thermal conductivity of the lower insulation effect The better) Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation The cost is still lower than the infusion process

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- I have a veteran to sell, because I just bought a new Taiwan, the price of ..

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- This kind of thing is generally money! The

- Q: Can sandwich panels be used for noise barriers?

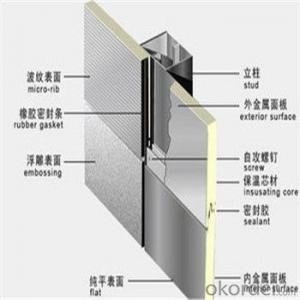

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- This is hard to say, depends on your house shape, height, height, regular rectangle of the province, the polygon will be more.

- Q: Are sandwich panels suitable for retail outlets?

- Yes, sandwich panels are suitable for retail outlets. Sandwich panels are made of two layers of rigid material with a core material in between. The rigid layers provide strength and durability, while the core material provides insulation and soundproofing properties. In a retail outlet, sandwich panels can be used for various purposes. They can be used as exterior cladding for the building, providing a sleek and modern look. The panels can also be used for interior walls and partitions, creating separate spaces within the store. Sandwich panels are easy to install and can be customized to fit the specific requirements of the retail outlet. They can be painted or decorated to match the branding and aesthetics of the store. Additionally, sandwich panels are lightweight and can be easily transported and assembled, making them a cost-effective choice for retail outlets. Furthermore, sandwich panels offer excellent thermal insulation, helping to keep the store cool in summer and warm in winter. This can lead to energy savings and a comfortable shopping environment for customers. Overall, sandwich panels are a suitable choice for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an attractive and functional solution for both the exterior and interior of the store.

Send your message to us

Polyurethane Insulation Foam Material for Discontinuous Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords