Insulated Concrete Sandwich Panels - Polyurethane Foam EPS Construction Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction material supplier rigid polyurethane foam sandwich panel EPS

1.Specifications

sandwich panel eps

1)Exterior, Interior

2)Waterproof, fireproof, soundproof

3)light weight wall board

4)Heat Insulation

5)Fast construction

2.Description:

Light weight energy-saving EPS Sandwich wall Panel

Composition: Calcium silicate board (face panel) + Cement and EPS (core) + Calcium silicate board (face panel)

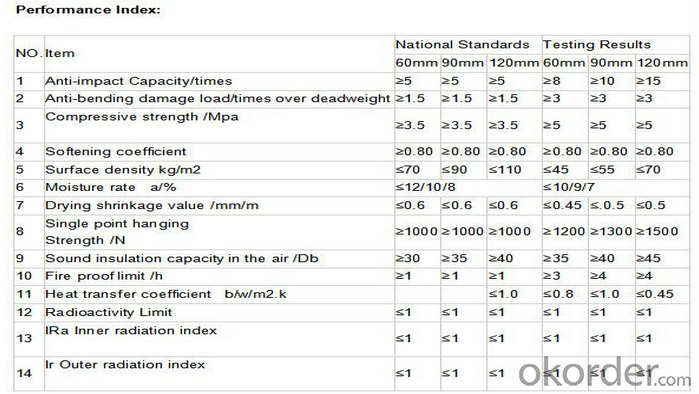

Quality Standard and guarantee :

3.Advantages:

Rapid installation

Easily transportable. On and off site – lightweight concrete

Strong and durable

Termite, Pest and Rot resistant

Excellent thermal/sound ratings

Superior quality and finishes. Takes all decorative treatments

Environmentally friendly

Easily worked. No special tools required

Excellent fire resistant qualities. Fire rated and load bearing

Cyclone and Earthquake resistant. Proven technology in emergency zones, preventative construction

Installation training available. For local unskilled labour and trade

4.Application:

Nonloadbearing wall, assembly houses, villas, public buildings, commercial buildings, residential houses, firewall, fire-rated warehouse, cold storage, etc.

This panel can work as substitute of traditional construction materials such as brick, hollow brick etc.

FAQ:

1,Could the size of the panel be changed?

Yes, we product accroding to the requirement.

2, What is the Minimum Production?

4000m2 perday x 8hours.

- Q: Color steel sandwich panels and color steel plate What is the difference

- Galvanized steel pipe is divided into cold galvanized steel pipe, hot galvanized steel pipe, cold galvanized steel pipe has been banned, which is also the country to promote the temporary use

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: How the exterior of the house is made of rock wool color steel sandwich panels

- Seek the name of the maintenance tool for the vehicle maintenance and the figure (all)

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- The inner panel can be installed with conventional technology, pay attention to the edge, the installation of corners, as well as their installation with the wallboard order, part of the first to install

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- . different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. . different insulation properties: the three polyurethane sandwich panels the best. . waterproof performance is different: the three polyurethane and EPS better than rock wool. . the density of different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally . polyurethane is generally 40. In short, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure, Have a number.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q: 50mm thickness of color steel foam sandwich board how much money a flat

- To strengthen safety education, training and safety technology. Article 4 Special operations personnel shall, after obtaining the Special Operations Operation Certificate, carry out the corresponding work; the construction unit shall not arrange for the operating personnel who have not obtained the "special operation operation certificate" to engage in special types of work. Article 5 Special operations personnel shall strictly implement the special operating procedures and the relevant safety rules and regulations, according to the chapter operation, refused to illegal command. Article 6 special operations personnel should carry their own documents, consciously accept the employer, the safety management department of the supervision and inspection. Article VII of the special operations personnel operations, the accident hidden or insecurity factors, should be to the site safety management and the relevant person in charge of the report.

- Q: The stove is dedicated to the plastic used for plastic paper

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, maintenance-free features, has been widely used Caigang sandwich panels Is the current building materials in a common product, not only can be a good flame retardant and environmentally friendly and efficient. Caigang sandwich board has two layers of metal panels and the middle of the polymer core insulation from the suppression. With the installation is simple, light and efficient light and efficient features. And the filling system used to close the molecular structure of the closed, you can put an end to the condensation of water vapor. The tile is used for the panel for the wall

Send your message to us

Insulated Concrete Sandwich Panels - Polyurethane Foam EPS Construction Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords