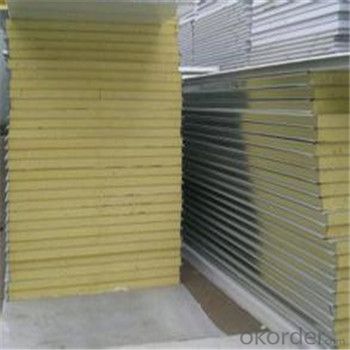

Honeycomb Core Sandwich Panels - Rockwool Sandwich Panel with 980mm 960mm/EPS Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Rockwool

1)Light weight,esay transport

2)Sound Insulation

3)Heat Insulation

4)waterproof

Rockwool sandwich panel with 980mm 960mm/EPS sandwich panel

Specification

1. External\Internal steel panel

Thickness: 0.2~0.5mm

Basic Steel: Galvanized Steel Coil, Zinc Alumine Steel Coil, Stainless Steel Coil

2. Core material

Type : Polysterene

Density: 8-24kg/m3

Width: 980mm 960mm 950mm 1150mm

Length: According to the customers' requests

Side steel strip or not : 0.2~0.5 mm galvanized steel (for roof )

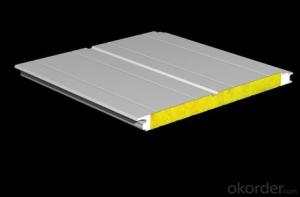

Eps Sandwich Panels

Polystyrene Sandwich panel(also called EPS Sandwich Panel)

Polystyrene is self-extinguishing. EPS Sandwich Panel has excellences of light weight(1/20-1/30 of concrete), heat insulation, rapid construction speed(operate withouthumidity and needn't repeated fitment). It is a new type protection structural material, congregates bearing, heat preservation and water resistance.

EPS sandwich panel specification as below :

Foam thickness | 50mm,75mm,100mm,120mm,150mm,200mm |

Foam density6 | 8-24kgs/m3 |

The top steel sheet and the back steel sheet thickness | 0.2-0.5mm |

Length | Due to continuous molding production,boards may need to be identified under the project in general should not be conditions of transport more than 12000mm |

Advantages of EPS sandwich panel:

1 light weight,

2 easy to install

3 various colour.

4 Sound Insulation,Heat Insulation.

5 The most waterproof.High hardness.

Eps Sandwich Panels

Application

Purification workshop , temeporary office, gymansia, villa, mobile building , guard booth etc. It is widely used for the wall and roof of steel building

Package and delivery

1) Delivery Time: with in15 days after receiving the deposit

2)package:standard export package

Product pictures

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: What is the difference between the board and the core board? The The

- General I-beam cross-section height of not less than 160mm

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- There is no harm have to brush your teeth ah ~ Do not you do not brush it? You are so powerful

- Q: Sandwich panels and Malacca ecological board what is the difference

- You can use the shear wall, and then hollow insulation can reduce the noise, but the cost of high

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q: What are the different types and uses of clean color steel plates?

- Playing glass glue, with a little better quality.

- Q: How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Clamp material, and pressure ah, a little bit of deformation of the clamp will lead to the next time the use of water leakage; some clamp is sealed with rubber ring, pressure, the rubber ring is not fully restored, will lead to Leakage of water; some cases in the pressure, the pipeline to the development of the process of training, but also lead to tight hoop tightly

- Q: 50mm thickness of color steel foam sandwich board how much money a flat

- To strengthen safety education, training and safety technology. Article 4 Special operations personnel shall, after obtaining the Special Operations Operation Certificate, carry out the corresponding work; the construction unit shall not arrange for the operating personnel who have not obtained the "special operation operation certificate" to engage in special types of work. Article 5 Special operations personnel shall strictly implement the special operating procedures and the relevant safety rules and regulations, according to the chapter operation, refused to illegal command. Article 6 special operations personnel should carry their own documents, consciously accept the employer, the safety management department of the supervision and inspection. Article VII of the special operations personnel operations, the accident hidden or insecurity factors, should be to the site safety management and the relevant person in charge of the report.

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- Never use the insulation board as a noise board, sound into the cavity can be converted into heat, closed cavity sound waves can not I am the most expensive, because the problem is good, but the quality of your use is not known

Send your message to us

Honeycomb Core Sandwich Panels - Rockwool Sandwich Panel with 980mm 960mm/EPS Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords