Composite Honeycomb Sandwich Panels - Light-Weight Energy-Saving EPS Cement Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | plastic shrink paper,card board corner ,wooden pallet,5-17 pcs/pallet |

| Delivery Detail: | within one month after received the deposit |

Specifications

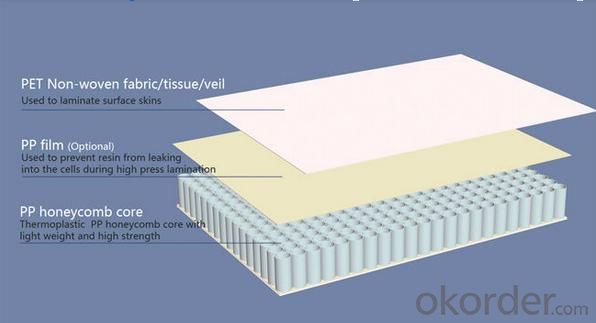

EPS cement sandwich panel using EPS,cement as main core material and silicon calcium board as surface board,compounded one time.

light-weight energy-saving EPS cement sandwich panel

EPS-cement sandwich panel Advantages:

1. Energy saving, Green, Environmental friendly

The raw materials do not include harmful substances. Energy-saving effects of the building is greatly improved It is highly recommended by the government.

2. Durable

70+ years building life span.

3. Strong

Hard surface and no damage after impacting. The hanging strength of single spot is 100kg, can nail and affix tile.

4. Fireproof

Panels have a fire rating of 4 hours. Grade A of National standard.

5. Sound insulation

The sound insulation capacity in the air is 35db-45db (according to National standard: GBJ121-88).

6. Waterproof, dampproof

No bead on wall panel surface in wet climate.

7. Quakeproof

More suitable for seismic & cyclone prone zones.

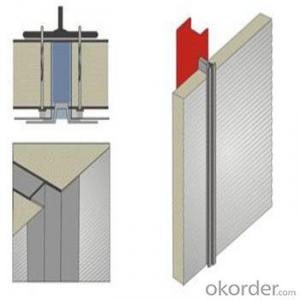

8. Unique tongue and groove

Specially designed tongue and groove arrangement ensures a perfect joint and makes construction faster.

9. Rapid installation

Being light in weight, handling & installation become very easy. One worker can do 20 sqm every day.

10. Dry working

It is very convenient, less building rubbish left after installation and clean up easily.

11. Excellent surface finish

The wallboard surface is level. You can plaster directly for inner decoration. It also can take all decorative treatment.

Villa&Exterior Wall System

Light weight compound sandwich panel can automatically adjust indoor air and water content with the season and climate changes, which can keep the temperature at an invariable temperature level ,and such ecology effect just goes with the tide of modern residential building. It is widely applied to various modular house ,low buildings, apartment, villas,and city house,etc.

Interior Partition System

With excellent fireproof, best hanging force, sound insulation, heat insulation, waterproof, easy

Installation and the like characteristics, light weight compound sandwich board have been widely

applying to the special positions like partition panel of high-rise and mega-high-rise buildings.

Roof System

Light weight compound sandwich panel roof system brings brand-new added value and application idea to the traditional roof construction. This system not only solves the problem of roof leakage,but also has the advantages such as heat insulation, neat joint surface, high temperature resistance, etc. The features of light weight and hight strength reduce the use of roof beam-column,reduce the consumption of materials,improve security;its easy construction time,which bring out its hight integrated performance-price ratio.

- Q: What is the difference between the board and the core board? The The

- General I-beam cross-section height of not less than 160mm

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- Safety Management 2. Civilized construction. Fastener steel scaffold 4. Door steel scaffold 5. Bowl button steel pipe scaffolding 6. Socket type plate fastener type steel scaffolding 7. Full house scaffolding 8. Suspended scaffolding 9. Attachment lift scaffolding 10. High operating basket 11. Foundation Pit Engineering. Template holder 13. High work 14. Construction electricity 15. Material hoist 16. Construction lift 17. Tower crane 18. Lifting hoisting. Construction equipment

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- What are the sub-items of the general project that should be prepared for the special safety program? What should be included in the special programming? The following dangerous parts of the sub-sub-projects and temporary electricity equipment in 5 and above or the total capacity of equipment in the 50kW and above the construction site of temporary electricity construction

- Q: 02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- Generally 6 meters outside the scaffolding,This is not clear!

- Q: Color steel sandwich board on the price of how much?

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture-proof effect is better than the solid wood particle board and wood sandwich board difference . solid wood particle board, is made of wood or other lignocellulosic material, after the application of adhesive Heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. . solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. . wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light-blocking. . fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Steel pipe is a steel pipe bowl buckle is the connection point like a bowl button is the connection point is a disk above a lot of hole pin is not a national standard thing is not recommended to use

Send your message to us

Composite Honeycomb Sandwich Panels - Light-Weight Energy-Saving EPS Cement Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords