Rockwool Sandwich Panels South Africa with Logo Cmax Prepared House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Rockwool sandwich panel

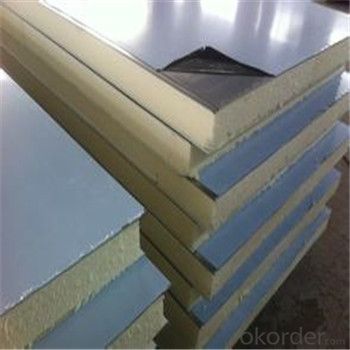

1.Material EPS/XPS/PU /PC wall panel

2.Composite sandwich panel

3.ISO9001:CE

4.Sandwich panel suppli

Rockwool sandwich panel

Henan B.R.D New Materials Co., Ltd devotes itself to producing green materials,Rockwool sandwich panel,

keeping Innovation, and be on the pursuit of quality first as well as integrity others.For the future,

we would still act up to our corporate vision to have the environmen-friendly materials to be more widely used.

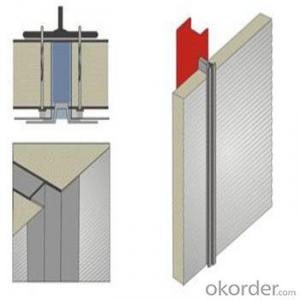

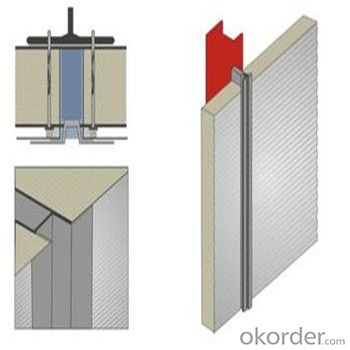

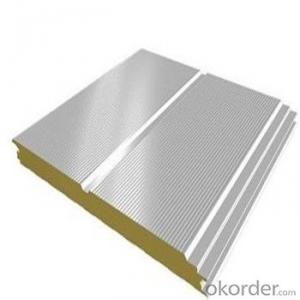

Rockwool sandwich panel and its manufacturing process is one the most advanced inventions, which in the factory automation equipment, rock wool and steel into a whole, thus changing the way of the rock wool plate before the compound required site , under the premise that meet the requirements of the building thermal insulation, sound insulation, fire protection, to achieve a high quality, efficient, reliable, safe target. The products in Europe through a wide range of applications, sophisticated.

Purposes: the company of rock wool sandwich panel roof and wall are two types of widely used in a fireproof, sound insulation, thermal insulation requirements of industrial and civil roof, external walls and internal partitions, especially fire demanding projects.

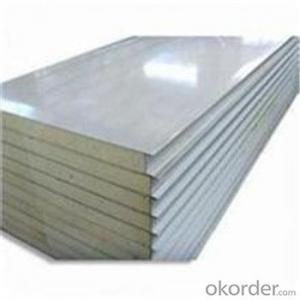

The up & down surface of this rockwool panel is Galvanized & Pre-painted steel sheets, core material is 5 components rockwool glue, it is formed by heating, foaming & laminating. Rockwool is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

1.Features:

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to 150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture effective.

4. Energy conservation, environmental protection, economical, heat insulting, good structure, easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

2.Specification:

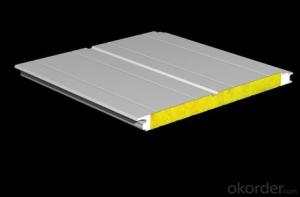

Steel Thickness | 0.4~0.8mm |

Panel thickness | 50/75/100/125/150 mm |

Effective width | (1) 950/mm ---for roof (2) 950/1000mm---for wall or ceiling |

Length | According to customer's request, less than 11.8m |

Materials | Inner is Rockwool, two sides is Color steel tile |

Structure | three layers: (1)upper layer is steel sheet, (2)the inner layer is Rockwool sandwich, (3)the bottom layer is also steel sheet |

Rockwool density | 30-50(kg/m³),etc |

color | blue, white grey, or other colors . |

Parts | Steel line for easy connect one by one Film covering in order to protect the steel of panels |

lifetime | 15~20 years |

Character | Light in weight, heat insulation, fireproof and water proof, environmental |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums ,etc |

Packing | Packed by shipping Container or according to your demands |

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- What are the best companies (including imported products) in China?

- Q: Reinforced concrete and metal sandwich board how much difference

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- (Polyurethane waterproof coating, asphalt, etc.); small gap, you can directly hit the silicone sealant; the same time, you can use the silicone sealant, Above all have to ensure that color steel plate fixed firmly, or if loose will damage the water

- Q: Sandwich panels and Malacca ecological board what is the difference

- Not count But it is best to mark the gun in the obvious place.

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. Sandwich panels are a type of construction material that consists of two outer layers (usually made of metal) with an insulating core in between. This combination of materials provides excellent thermal insulation, fire resistance, and soundproofing properties, making them ideal for train station applications. The insulation properties of sandwich panels help to regulate the temperature inside the train station, ensuring a comfortable environment for passengers and staff regardless of external weather conditions. This can help reduce energy consumption and lower heating or cooling costs. Sandwich panels are also highly fire-resistant, which is crucial for train stations where the risk of fire is a major concern due to the presence of electrical systems, passengers, and potentially flammable materials. The fire-resistant properties of sandwich panels can help contain and slow down the spread of fire, providing valuable time for evacuation and firefighting efforts. Furthermore, sandwich panels offer excellent soundproofing capabilities. Train stations are typically noisy environments due to the constant movement of trains, announcements, and passenger conversations. The use of sandwich panels can significantly reduce noise transmission, creating a more peaceful and comfortable atmosphere for passengers and staff. Additionally, sandwich panels are lightweight and easy to install, making them a cost-effective and efficient choice for train station construction or renovation projects. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are indeed suitable for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, providing a positive experience for both passengers and staff.

- Q: 02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- Scaffolding decoration and use, is the construction of the scaffolding, after the construction is not removed, and then as a decoration construction, do not repeat structures, do not repeat charges.

- Q: Color steel sandwich panels and synthetic resin tile which is more market

- Must be embedded in the concrete beam on the concrete beam, and then fasten the steel pipe connection, the use of steel connection, the connection point can be 2 steps 3 cross, the specific calculation by the book construction

Send your message to us

Rockwool Sandwich Panels South Africa with Logo Cmax Prepared House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords