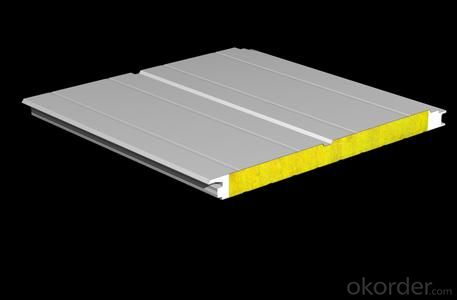

Phenolic foam color steel laminboard

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

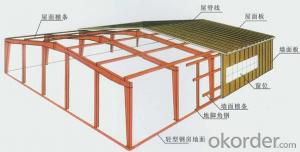

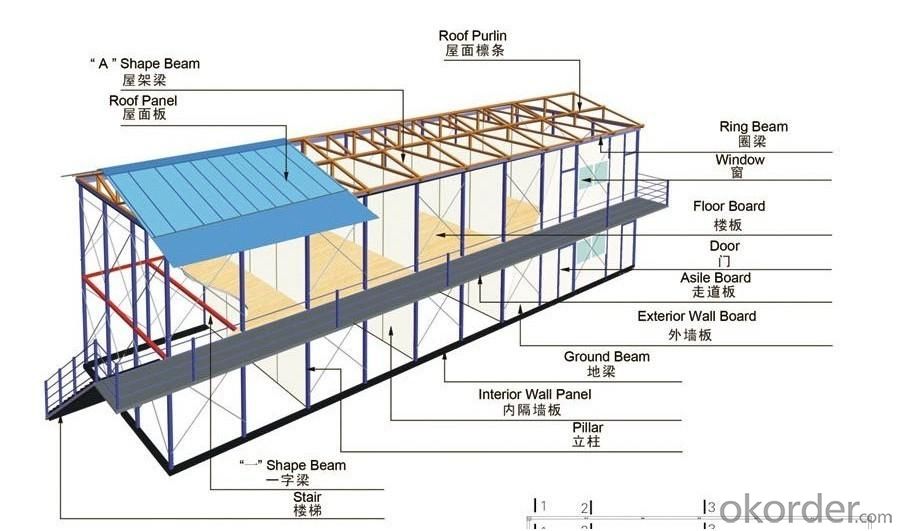

Fireproof Panels Prefab House/color steel laminboard

1.Stable Frame,Easy to assembly&disassembly

2.Extensive application house

Fireproof Panels Prefab House/color steel laminboard

1.Stable Frame,Easy to assembly&disassembly

2.Extensive application house

Fireproof panels prefab house portable metal house

High Quality Color Steel Structure Frame Portable House

Double slope housetop removable houses

Other Name:prefabricated prefab modular portable house/ prefabricated house/prefab house/

portable shelter/color steel laminboard

Color steel laminboard Main advantages :

1.Stable Frame:Light and flexible frames provide safe and fulfill requirements.

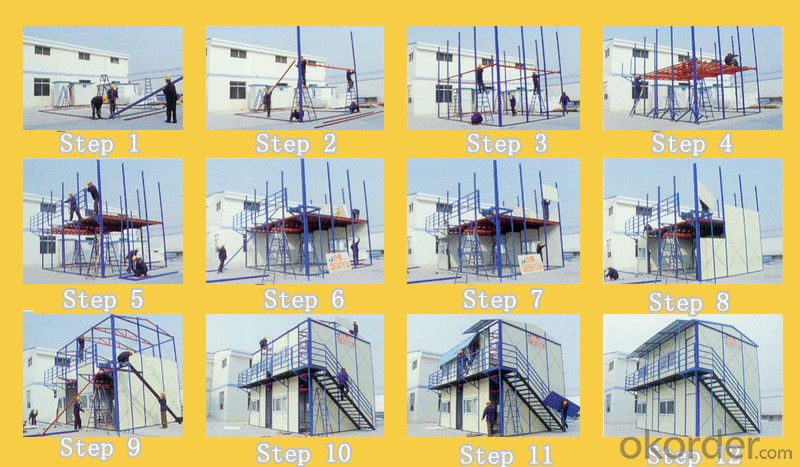

2.Easy to assembly&disassembly:

Several reuse, simple tools installation.One worker can install 20-30 sqm per day, six workers could work out 3K×10K × 3P house in two days.

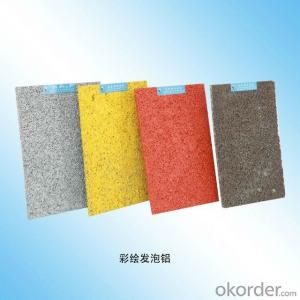

3.Beautiful decoration: Beautiful materials, brightly color, flat surface and art decoration.

4.Flexible composition: Doors and windows could be installed in any position, separate wall could

be built at any transverse axis.

5.Waterproof: Waterproof structure, there is no other waterproof processing.

6.Longevity:Steel materials has been processing, its usage is about 10 years.

7.Environmental friendly:Professional design, easy installation, recycle using, no construction craps.

Its cost is much more lower than other materials.Various styles: Standard component, long and wide

use (1K=1820mm) as unit. The transverse distance is mK+160,portrait distance is nK+160.

8.Extensive application: It is widely used in road, railway, and other wild temporary house, also in

government project ,business and others, such as office, headquarters, shop, dormitory, park,

school, hospital, exhibition, and gas station.

Prefab House Technical Parameters:

A)Overall weight:50~60kg/sqm

B)Seismic fortification intensity:8 grade

C)Wind-proof capacity:wind speed 20m/s, resist 8 grade wind

D)Floor loading capacity:150kg/sqm

E)Roof loading capacity:60kg/sqm

F)External wall bearing capacity:50kg/sqm

Portable House Main Materials:

No. | component | specification | material thickness | remark | |||||||

1 | ground beam | 8#C steel | 1.8mm | black paint | |||||||

2 | column | double 8#C steel | 1.8mm | blue paint | |||||||

3 | transverse beam | double 8#C steel+50×30 square tube | 1.8mm | blue paint | |||||||

4 | fastigium transverse beam | 8#C steel | 1.8mm | blue paint | |||||||

5 | flooring purlin | 8#C steel | 1.8mm | blue paint | |||||||

6 | horizontal bracket | angle iron | 2.0mm | blue paint | |||||||

7 | roof "A"shape beam | 8#C steel+50×30 flat tube | 1.8mm+1.0mm | iron red | |||||||

8 | roof fastigium "A"shape beam | 8#C steel | 1.8mm | iron red | |||||||

9 | roof purlin | 50×30 flat tube | 1.0mm | iron red | |||||||

10 | shelf bracket | 8#C steel | 1.8mm | blue paint | |||||||

11 | platform bracket | 8#C steel | 1.8mm | blue paint | |||||||

12 | platform column bracket | 50 round tube | 1.2mm | blue paint | |||||||

13 | staircase | pattern plate | 3.0mm | black paint | |||||||

14 | handrail | 30×30 square tube | 1.0mm | blue paint | |||||||

15 | walkway plate | pattern plate | 3.0mm | black paint | |||||||

16 | balustrade | 30×30 square pipe | 1.0mm | blue paint | |||||||

17 | roof tile | 830 type PU tile | 18mm | sky blue | |||||||

18 | external wall panel | 50mm EPS with two-sides color steel sandwich panel | 0.326mm for color steel sheet | grey white | |||||||

19 | partition wall panel | 50mm EPS with two-sides color steel sandwich panel | 0.326mm for color steel sheet | grey white | |||||||

20 | door | color steel sandwich panel door | 870mm(W) × 2100mm(H) | grey white | |||||||

21 | window | PVC sliding window | 1748mm(W) × 925mm(H) |

| |||||||

22 | canopy frame | 8#C steel | 1.8mm | blue paint | |||||||

23 | canopy frame bracket | 25 round tube | 2.0mm | blue paint | |||||||

24 | floorslab | plywood | 15mm |

| |||||||

25 | paint | LVSHU BRAND alkyd paint

| |||||||||

Other Related Product we can also supply, Feel free to contact us if you have any requirement!

- Q: Reinforced concrete and metal sandwich board how much difference

- JGJ130 has regulations. Not more than 0.4L, and not more than 500mm

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- 5 cm, 10 cm, 15 cm and 25 cm The general material 5 cm price between 45 to 75 yuan; 75 cm price of 55 to 90 yuan range; 10 cm price of 70 to 100 yuan, Caigang Caigang purification plate thickness can also Custom So we must first understand their choice of materials and thickness, different scenes of the plate is not the same choice

- Q: Sandwich panels and Malacca ecological board what is the difference

- You can use the shear wall, and then hollow insulation can reduce the noise, but the cost of high

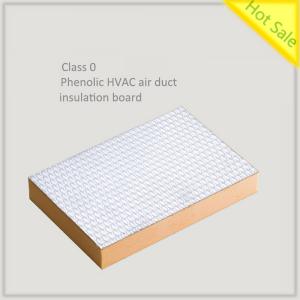

- Q: Are sandwich panels suitable for food kiosks?

- Sandwich panels are indeed appropriate for food kiosks. They have gained significant popularity in the construction industry due to their durability, insulation properties, and ease of installation. These panels consist of two external layers, typically constructed from metal, and a core material, such as polyurethane foam or rockwool, which offers outstanding thermal insulation. To meet food safety regulations, food kiosks necessitate a hygienic and clean atmosphere. Sandwich panels provide a smooth, non-porous surface that is simple to clean and maintain, making them an ideal choice for food kiosks. Furthermore, these panels offer thermal insulation, helping to maintain the appropriate temperature for storing and serving food, regardless of the climate. In addition, sandwich panels are lightweight, facilitating effortless transportation and assembly. This allows for quick setup and relocation if necessary. Moreover, they possess remarkable structural strength, ensuring stability and security for the kiosk. All in all, due to their durability, insulation properties, hygienic surfaces, and ease of installation, sandwich panels are a suitable option for food kiosks.

- Q: Can sandwich panels be used for noise barriers?

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: How does the wall rock wool sandwich panel be installed?

- will be fixed on the wall insulation material, play a warm and warm role in warm technology

- Q: Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- General color steel foam sandwich panels. Price in the 45 - 60 yuan / M ? or so.

Send your message to us

Phenolic foam color steel laminboard

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords