Polyethylene Sandwich Panels - PPGI, PPGL, GI, GL, CR, Corrugated Steel Sheet, Color Steel Lamination

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy),with pallet |

| Delivery Detail: | 20-25 days after receiving the deposit |

Specifications

PPGI, PPGL , GI , GL, CR and Corrugated steel sheet

thickness : 0.12mm to 1.2mm,

width :600mm to 1500mm

zinc coat:30-275g

We can offer PPGI and GI in thickness available from 0.12mm to 1.2mm, width available from 600mm to 1500mm

Basic information

1: Size: 0.15-1.2mm*600-1250mm

2: Paint: Top side: 15-25um, Back side: 5-9um, or according to customer’s order.

3: Base material: Hot dipped galvanized steel coil, GL

4: Zinc coating: 30-275g.

5: Coil weight: 3-6tons

6: Coil ID: 508mm

7: Color: Any color.

8: Standard: ASTM, GB, JIS

9:Grade: CGCC,CGCH,SGCC, DX51D and ASTM

10:Surface Treatments: skin passed, chromated, oiled and antifinger

11: Approved Certificate: SGS / ISO9001 / BV

12: Package Method: Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy)

13: Payments terms: T/T ,L/C,etc.

Brief Introductionof product

1. Color Coated steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Color Coated Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color Coated Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Color Coated Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Color Coated Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

SGLCC | 140-350 | 270-500 | 22 |

SGLCD | 140-300 | 270-420 | 26 |

SGLCDD | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Or the whole building with the framework of the masonry, or steel structure with masonry Steel structure with the concrete in the economy is very optimistic Just the structure is at least 30% higher than the concrete structure, because at present our steel is relatively small

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- It should be, for example, naphthalene anthracene, and several rings are capable of forming a closed conjugate system. Generally speaking, more than four benzene rings are fused (for example, 1.2-benzo, 3-methyl Anthracene, etc.) are mostly carcinogenic substances, which are mostly anthracene derivatives, the relationship between the mechanism of carcinogenesis and structure is not yet fully understood ...

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- The metal hose is an important connecting member in engineering technology

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- China's Ministry of Construction and other four ministries and commissions also issued a clear from the 2000 single tiger toilet mortar 丿 hinge paint closed from the galvanized pipe as a water supply pipe, the new district of cold water pipes have been rarely used galvanized pipe, and some district heat Water pipes are galvanized pipes

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

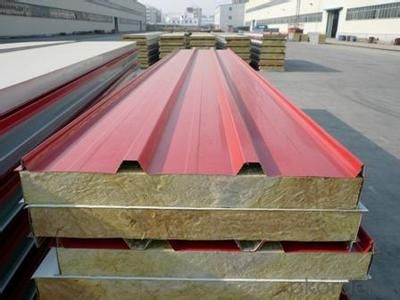

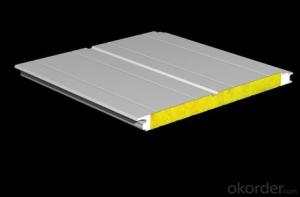

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: Are sandwich panels suitable for retail outlets?

- Sandwich panels, consisting of two rigid layers and a core material, are ideal for retail outlets. With their strength and durability, the rigid layers ensure longevity, while the core material provides insulation and soundproofing. In a retail setting, sandwich panels serve various purposes. They can serve as sleek and modern exterior cladding, enhancing the building's appearance. Additionally, they can be utilized for interior walls and partitions, creating distinct areas within the store. The installation of sandwich panels is effortless, and they can be tailored to meet the specific requirements of the retail outlet. They can be painted or adorned to align with the store's branding and aesthetics. Moreover, their lightweight nature enables easy transportation and assembly, making them a cost-effective choice. The benefits of sandwich panels extend beyond aesthetics. They offer exceptional thermal insulation, ensuring a comfortable shopping experience regardless of the season. This leads to energy savings and a pleasant environment for customers. Ultimately, sandwich panels are a suitable option for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an appealing and functional solution for both the store's exterior and interior.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

Send your message to us

Polyethylene Sandwich Panels - PPGI, PPGL, GI, GL, CR, Corrugated Steel Sheet, Color Steel Lamination

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords