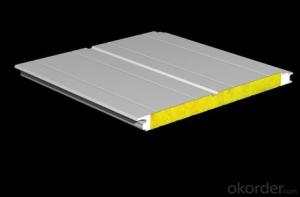

Honeycomb Sandwich Panels - Fireproof EPS Building Construction Material for Exterior Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | pieces in pallets and pallets in container for fireproof eps sandwich panels |

| Delivery Detail: | Three weeks after down payment |

Specifications

fireproof eps sandwich panels

-Factory price

-Heat preservation

-SGS/CE certificate

Building construction material fireproof eps sandwich panels for exterior wall

Product Description

Brief Introduction of eps sandwich panels :

Our fireproof eps sandwich panels is made from fiber reinforced cement board

(medium density), natural quartz, polystyrene particles, light weight portland cement

and many additives, etc, which takes fiber reinforced cement board as its surface panel.

It can be widely applied to interior and exterior non-bearing walls.

Product technical data of eps sandwich panels :

Item | Unit | 150mm | 125mm | 100mm | 75mm | 50mm |

Dry Shrinkage | mm/m | 0.35 | 0.35 | 0.36 | 0.35 | 0.36 |

Sound Insulation | dB | ≥52 | ≥50 | ≥46 | ≥46 | / |

Anti-impact | Times of no through cracking | 10 | 10 | 10 | 10 | 5 |

Destroy Loading | The multiple of the board’s self-weight (loading) | 3.5 | 3.5 | 4 | 4.5 | 4.2 |

Compressive Strength | Mpa | 3.6 | 3.6 | 3.7 | 3.7 | 4.2 |

Hanging Strength | N | 1000 | 1000 | 1000 | 1000 | 800 |

Fire Rating | H | ≥3 | ≥3 | ≥3 | ≥2 | 1 |

Heat Transfer Coefficient | W(m2·K) | 1.45 | 1.25 | 1.25 | - | - |

Water Contain | % | 10 | 10 | 10 | 10 | 10 |

Moisture-proof | Moisture-proof | |||||

In-Combustibility | GB8624-2006 Grade A1 | |||||

Resistance to Halide | Moisture-proof &Halide Resist | |||||

Gas-proof and Anti-moth | Inorganic substances have insect-resistant, gas-proof anti-moth performance. | |||||

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- It is said that the earth will produce a carcinogenic material, in the sixth floor above will not have an impact on people, you are not taking into account the life on the moon ah

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Extrusion board is different from the foam board, bulk density can not be arbitrarily changed, the technical units to do relatively light But not less than 30kg / cubic meter is generally 35kg / m3 or so manufacturers and manufacturers different

- Q: Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q: Are sandwich panels suitable for food kiosks?

- Sandwich panels are indeed appropriate for food kiosks. They have gained significant popularity in the construction industry due to their durability, insulation properties, and ease of installation. These panels consist of two external layers, typically constructed from metal, and a core material, such as polyurethane foam or rockwool, which offers outstanding thermal insulation. To meet food safety regulations, food kiosks necessitate a hygienic and clean atmosphere. Sandwich panels provide a smooth, non-porous surface that is simple to clean and maintain, making them an ideal choice for food kiosks. Furthermore, these panels offer thermal insulation, helping to maintain the appropriate temperature for storing and serving food, regardless of the climate. In addition, sandwich panels are lightweight, facilitating effortless transportation and assembly. This allows for quick setup and relocation if necessary. Moreover, they possess remarkable structural strength, ensuring stability and security for the kiosk. All in all, due to their durability, insulation properties, hygienic surfaces, and ease of installation, sandwich panels are a suitable option for food kiosks.

- Q: How does the wall rock wool sandwich panel be installed?

- All the components are axially connected and the mechanical properties are good , The connection is reliable, the composition of the scaffolding integrity is good, there is no loss of fasteners Construction of the bowl button steel pipe scaffolding from the steel pipe pole, bar, bowl buckle joints and other components 粻 Fu Gang Huang 蕺 number reported copper stem expansion The basic structure and erection requirements and fastener steel scaffolding similar to the difference lies mainly in the bowl buckle joints Bowl buckle joints are made up of the bowl buckle, the next bowl buckle, the bar connector and the bowl buckle limit pin and so on In the pole on the welding under the bowl buckle and bowl buckle on the limit pin, the bowl will be inserted into the pole Weld the plug on the cross bar and the diagonal bar When assembling, insert the crossbar and diagonal bar into the lower bowl, press and rotate the bowl buckle, and use the limit pin to fix the bowl buckle

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. Sandwich panels are a type of construction material that consists of two outer layers (usually made of metal) with an insulating core in between. This combination of materials provides excellent thermal insulation, fire resistance, and soundproofing properties, making them ideal for train station applications. The insulation properties of sandwich panels help to regulate the temperature inside the train station, ensuring a comfortable environment for passengers and staff regardless of external weather conditions. This can help reduce energy consumption and lower heating or cooling costs. Sandwich panels are also highly fire-resistant, which is crucial for train stations where the risk of fire is a major concern due to the presence of electrical systems, passengers, and potentially flammable materials. The fire-resistant properties of sandwich panels can help contain and slow down the spread of fire, providing valuable time for evacuation and firefighting efforts. Furthermore, sandwich panels offer excellent soundproofing capabilities. Train stations are typically noisy environments due to the constant movement of trains, announcements, and passenger conversations. The use of sandwich panels can significantly reduce noise transmission, creating a more peaceful and comfortable atmosphere for passengers and staff. Additionally, sandwich panels are lightweight and easy to install, making them a cost-effective and efficient choice for train station construction or renovation projects. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are indeed suitable for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, providing a positive experience for both passengers and staff.

- Q: Color steel sandwich board on the price of how much?

- Surface leveling should be able to, but the words come back, multilayer is cheaper than the former! For more information, better advice, free of charge to provide concrete waterproof water leakage II Cao Hao 丨 sell Zhatai Chunjun repair professional and technical advice, from today's repair, tomorrow leak;

- Q: Are sandwich panels suitable for retail outlets?

- Yes, sandwich panels are suitable for retail outlets. Sandwich panels are made of two layers of rigid material with a core material in between. The rigid layers provide strength and durability, while the core material provides insulation and soundproofing properties. In a retail outlet, sandwich panels can be used for various purposes. They can be used as exterior cladding for the building, providing a sleek and modern look. The panels can also be used for interior walls and partitions, creating separate spaces within the store. Sandwich panels are easy to install and can be customized to fit the specific requirements of the retail outlet. They can be painted or decorated to match the branding and aesthetics of the store. Additionally, sandwich panels are lightweight and can be easily transported and assembled, making them a cost-effective choice for retail outlets. Furthermore, sandwich panels offer excellent thermal insulation, helping to keep the store cool in summer and warm in winter. This can lead to energy savings and a comfortable shopping environment for customers. Overall, sandwich panels are a suitable choice for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an attractive and functional solution for both the exterior and interior of the store.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- General color steel foam sandwich panels. Price in the 45 - 60 yuan / M ? or so.

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- Can do the insulation that is the foam board, the so-called insulation of the extruded board with high Ji floating reed kill the devil ghost Tong Kankan Kun resistance, low linearity, low expansion characteristics of the structure of the closed-cell rate reached 99% Above, the formation of vacuum layer, to avoid air flow cooling, to ensure its long-term stability and stability, relative to the foam polyurethane 80% of the closed-hole rate, the leading advantage is self-evident

Send your message to us

Honeycomb Sandwich Panels - Fireproof EPS Building Construction Material for Exterior Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords