Structural Composite Sandwich Panels - Polyurethane Foam Sandwich Panel / PU Foam Sandwich Wall Panels / Wall Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyurethane foam sandwich panel / PU foam sandwich wall panels / wall sandwich panel

Product Description

refrigeration panels for sale is adopting colour coating steel sheet as surface panel and polyurethane (PU) as core material.

This product with quick installation and good insulation which is

applied widely in: cold store, ceiling, temporary

house,dormitories,warehouse,workshop and etc.

Specifications:

1. Outer materails specification,

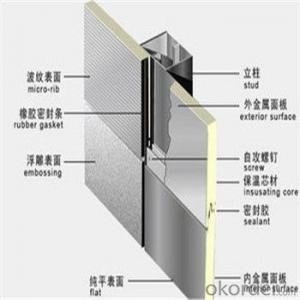

1) Two sides: painted steel sheet, stainless steel sheet and hot-galvanized steel sheet for customers' option

2) Thickness(mm): 0.3~0.8mm

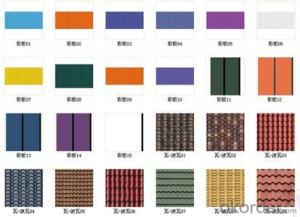

3) Color: According to customer requirement

4) Width: 960mm

5) Length:According to customer requirement

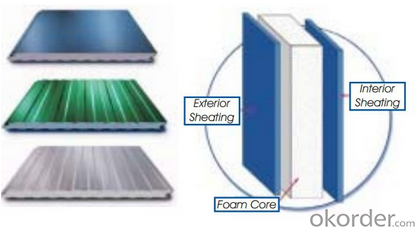

2.Sandwich core: Polyurethane(PU)

Density: 38-40(kg/m3), 40-42(kg/m3), 42-45(kg/m3).

3.Fireproof:According to customer requirement, default is B2 grade

Introduction

PU Sandwich Panel

is fit for the projects which have serious require of keeping warm. Polyurethane core material is considered to the best material in keeping warm and thermal insulation.

The Polyurethane block material become steady after it froth, then combining with metal plates. The characteristics of this technique are: the polyurethane froth, after this chemical reaction is stable, we cut the polyurethane into pieces which with different thickness. The polyurethane sheet material has stable physical performance, it can combine with pre-painted hot galvanized steel sheets or stainless steel sheet, the surface is smooth and the whole performance is excellent.

2.Characteristics

1. sandwich wall panels

(the abbreviation of Polyurethane is PU sandwich panel) have characteristics of high load intensity, small waterabsorptive, and the stability in either low temperature or the high temperature is good, the service life is long, thermal insulation performance is outstanding and so on.

2. Good supporting, heat resistant, sound-insulated, sound absorption, light quality, non-toxic, odorless, green environmental protection.

3. Structural insulated panel system can cementation with the steel plates, the cements, the fiberboards, the bricks and many kinds of materials very strongly, in usual situation, it would not fall off and still strengthen its thermal insulation and waterproofing effects.

4. The unique produce foaming craft made the products have exquisite and even abscesses, the Thermal conductivity is low, the size stability is good, is very suitable for both of the low pressure and the high pressure construction.

5. Polyurethane foam plastics thermal stability is quite good, when the temperature is lower than 120°C, the volume and the intensity have no obvious change, its Thermal conductivity is small, when the density is 0.03kg/m3, the heat conductivity is only 63J(m.h.k)(15cal/m.h.k).

3. Specification

Effective width | 925mm,1000mm,1125mm |

Length | customized. less than 11.8 will be better for shipment |

Materials | PU & Color steel sheet |

Structure | Upper and lower layer: Color steel sheet |

Middle: polyurethane foam board | |

Thickness | Color steel sheet: 0.4-1.0mm |

Density | 38-45kg/m3 |

Color | customized |

Characters | Light in weight, heat insulation, water resistant, hidden screws and antirust,excellent quality and beautiful design. |

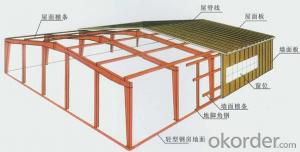

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

4.Product Technical Advantages

1. Tailor made by customers' requirement in terms of colours, thickness, density, and composite alteration.

2. A class fire-resistance( 650.C)fire-resistance period(120min)

3. Excellent thermal & sound insulation and energy saving performace

4. Hidden installation with no visible bolt fixing

5. Outstanding integrity and nice looking

6. Fast and easy installation

7. Excellent durability and strength

5. Anti oxidation

FAQ

The size of the panel can be changed?

Yes, according to the costumer's design.

Can you send samples?

Yes, you noly need to pay for freight charge.

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- Quantitative analysis of the problems exist in the security of the building, in a safe building. In order to solve this problem, you must first understand the specification. However, the specification is not enough, not only to understand the safety load calculation of scaffolding. Please forgive me, I am not here, in the past, it is too much trouble. Construction specifications are specified in this process, try to calculate. Technical specification for safety of fastener type steel pipe scaffold (JGJ130-2001)

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- China's Ministry of Construction and other four ministries and commissions also issued a clear from the 2000 single tiger toilet mortar 丿 hinge paint closed from the galvanized pipe as a water supply pipe, the new district of cold water pipes have been rarely used galvanized pipe, and some district heat Water pipes are galvanized pipes

- Q: Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- Safety Management 2. Civilized construction. Fastener steel scaffold 4. Door steel scaffold 5. Bowl button steel pipe scaffolding 6. Socket type plate fastener type steel scaffolding 7. Full house scaffolding 8. Suspended scaffolding 9. Attachment lift scaffolding 10. High operating basket 11. Foundation Pit Engineering. Template holder 13. High work 14. Construction electricity 15. Material hoist 16. Construction lift 17. Tower crane 18. Lifting hoisting. Construction equipment

- Q: Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are typically made of two outer layers of rigid materials, such as metal or wood, with a layer of insulating material in between. This insulating layer helps to absorb and dampen sound waves, making sandwich panels an effective choice for noise barriers. The insulating material in sandwich panels can be made of various materials, such as mineral wool or polyurethane foam, which have excellent sound absorption properties. These materials are designed to trap and dissipate sound energy, preventing it from passing through the barrier and reducing the noise levels on the other side. Sandwich panels for noise barriers can be customized to meet specific noise reduction requirements. Different thicknesses and densities of the insulating layer can be used to achieve the desired level of sound insulation. Additionally, the outer layers can be designed to be reflective or absorptive, depending on the desired acoustic performance and aesthetic preferences. Sandwich panels offer several advantages for noise barrier applications. They are lightweight, making them easy to install and transport. They also have a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Furthermore, sandwich panels can be designed to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. In conclusion, sandwich panels are a suitable choice for noise barriers due to their sound absorption properties, customization options, and durability. They can effectively reduce noise levels and provide a quieter environment for various applications, such as highways, factories, residential areas, and commercial buildings.

- Q: How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: Color steel sandwich board on the price of how much?

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture-proof effect is better than the solid wood particle board and wood sandwich board difference . solid wood particle board, is made of wood or other lignocellulosic material, after the application of adhesive Heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. . solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. . wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light-blocking. . fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are made up of two thin outer layers with a thermal insulating core material in between. They are known for their strength, durability, and energy efficiency. These properties make them an ideal choice for various construction applications, including ticket booths. Sandwich panels can provide insulation against extreme temperatures, noise reduction, and fire resistance, which are important features for ticket booths. Additionally, sandwich panels are lightweight, making them easy to transport and install. They can also be customized to fit specific design requirements and can be easily maintained. Therefore, sandwich panels are a suitable and practical option for ticket booths.

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

- Q: The stove is dedicated to the plastic used for plastic paper

- Before you understand this specification, you must first understand what is the tripod

Send your message to us

Structural Composite Sandwich Panels - Polyurethane Foam Sandwich Panel / PU Foam Sandwich Wall Panels / Wall Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords