Polyurethane (PU) Foam Sandwich Panel Composite with Aluminum Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

CMAX PU Foam Sandwich Panel for air conditioning

CFC HCFC Free Environment Freindly

Low thermal conductivity

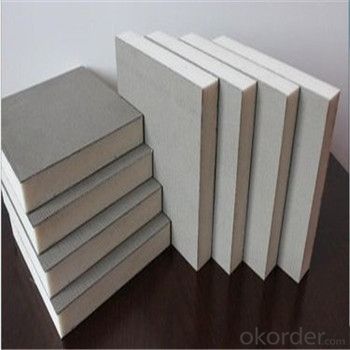

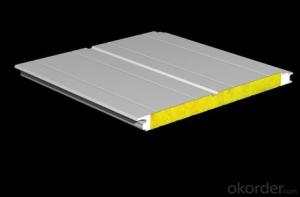

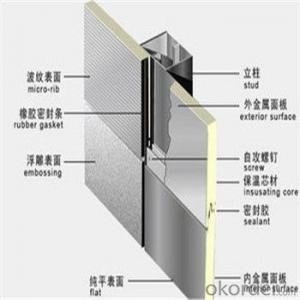

CMAX Polyurethane (PU) Foam Sandwich Panel for air conditioning is widely used for the air distribution of central air duct system, which is one of the most advanced and energy-saving air duct systems. The system is composed of CFC & HCFC free Polyurethane Foam Pre-insulated air duct panel and professional supporting accessories & tools. By taking the rigid insulation foam as the core material and covered with embossed/smooth Aluminum foil on both sides, PU Foam Pre-insulated air duct panel obtains excellent performances of low vapor permeability, thermal resistance and good toughness property, which is also environment Friendly.

Specification of Polyurethane (PU) Foam Pre-insulated Duct Panel:

Item | Unit | Specification |

Panel Structure | Alu./Foam/Alu. | |

Standard Panel Size | mm | 3950*1200*20 |

Alu. Foil Thickness | mm | 0.06 |

Alu. Foil Thickness | mm | 0.06 |

Foam Density | kg/m3 | 55 |

Thermal Conductivity | w/m.k | 0.021 |

Compressing Strength | Mpa | 0.2 |

Bending Strength | Mpa | 2 |

Water Absorption | % | ≤0.1 |

Dimension Change | % | 0.3 |

Working Temperature | °C | -100 to +80 |

Maximum Allowable Wind Velocity | m/s | ≤12 |

Continuous Running Maximum Temperature | °C | ≤70 |

Advantages of Polyurethane(PU) Pre-insulated HVAC Ductwork:

1. Lower heat conductivity, higher thermal efficiency

2. Low density, light weight

3. Foamed with CFC free materials, environment protective

4. Hermetic seal ensures little air leakage

5. With aluminum foil reinforced on both sides, its corrosion protective, hygeian, and has a beautiful appearance.

6. Foamed with closed-cell structure, its water-proof and sound-insulated.

7. Easy making, rapid installing and convenient maintenance saves cost.

8. No protrudent flange on the connections, it can save a lot of building space.

FAQ:

1. Could be changed the size of the panel?

Yes, according to your requirement.

2. What is the minimum production?

4000 m2 x 1day x 8 hours.

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Single row of scaffolding, that is, the entire frame by a row of pole composition; due to its small range (generally only used in decorative construction), poor stability, erection height is small, has gradually withdrawn from the construction market

- Q: Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Insulation, fire, noise, the most important fire performance, fire resistance, corrosion resistance, long service life!

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: General color steel foam sandwich panels. How much a square is flat

- Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement The outermost front panel is called a panel, and the back is called a backplane The inner board is called the core plate Ask the question? The They said that the use of the shoe cabinet, wardrobe with a sandwich panel answer:

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- . different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. . different insulation properties: the three polyurethane sandwich panels the best. . waterproof performance is different: the three polyurethane and EPS better than rock wool. . the density of different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally . polyurethane is generally 40. In short, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure, Have a number.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: Are sandwich panels suitable for retail outlets?

- Sandwich panels, consisting of two rigid layers and a core material, are ideal for retail outlets. With their strength and durability, the rigid layers ensure longevity, while the core material provides insulation and soundproofing. In a retail setting, sandwich panels serve various purposes. They can serve as sleek and modern exterior cladding, enhancing the building's appearance. Additionally, they can be utilized for interior walls and partitions, creating distinct areas within the store. The installation of sandwich panels is effortless, and they can be tailored to meet the specific requirements of the retail outlet. They can be painted or adorned to align with the store's branding and aesthetics. Moreover, their lightweight nature enables easy transportation and assembly, making them a cost-effective choice. The benefits of sandwich panels extend beyond aesthetics. They offer exceptional thermal insulation, ensuring a comfortable shopping experience regardless of the season. This leads to energy savings and a pleasant environment for customers. Ultimately, sandwich panels are a suitable option for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an appealing and functional solution for both the store's exterior and interior.

Send your message to us

Polyurethane (PU) Foam Sandwich Panel Composite with Aluminum Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords