Sandwich Panels in High Quality for Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

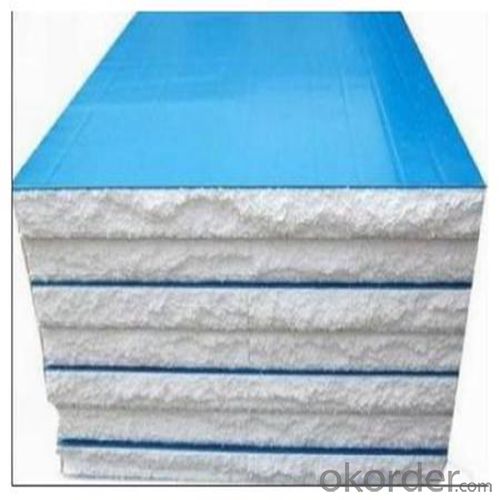

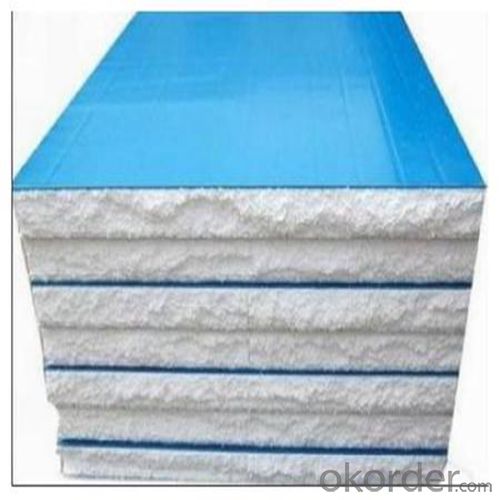

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

1) How to guarantee the quality of the products?

2) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) what policy for broken parts?

4)within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: What is the difference between a smooth and perforated stainless steel sheet?

- A smooth stainless steel sheet is one that possesses a uniform and flat surface, devoid of any visible texture or patterns. It finds its typical usage in scenarios where a sleek and polished appearance is sought after, like in architectural designs or decorative elements. In contrast, a perforated stainless steel sheet is characterized by the presence of small or large holes that have been punched or drilled into it, resulting in an arrangement of openings on its surface. These openings can take various shapes, such as round, square, or any other, depending on the desired aesthetic or functional requirements. Perforated sheets are commonly employed in situations where ventilation, filtration, or visibility is necessary, such as in industrial equipment, acoustic panels, or safety grating. The primary distinction between a smooth and perforated stainless steel sheet lies in the presence or absence of holes on the surface. While a smooth sheet offers a pristine and uninterrupted appearance, a perforated sheet offers several advantages, including improved airflow, enhanced visibility, and increased sound absorption. Furthermore, the choice between a smooth or perforated sheet hinges on the specific application and the desired functionality. Smooth sheets are ideal for situations that call for a seamless and polished look, while perforated sheets are well-suited for applications that necessitate functionality, such as filtering, screening, or facilitating airflow.

- Q: What are the different sheet metal piercing techniques for steel sheets?

- Steel sheets can be pierced using various techniques. These methods are employed to create holes or openings in the sheets based on specific requirements. Here are several different techniques for piercing: 1. Punching: Punching is a widely utilized technique that involves using a punch and die set to create holes in steel sheets. The punch is forced through the sheet, cutting out the desired hole shape or size. This technique is efficient and can be applied to a range of hole sizes and shapes. 2. Drilling: Drilling is another commonly employed technique for piercing steel sheets. It entails rotating a drill bit at high speed to create a hole in the sheet. Drilling is often used for smaller holes or when precision and accuracy are paramount. 3. Laser cutting: Laser cutting is a highly precise and versatile technique for piercing steel sheets. It employs a high-powered laser beam that is focused on the sheet, melting and vaporizing the material to create holes or shapes. Laser cutting offers high-speed production and can achieve complex designs with exceptional accuracy. 4. Notching: Notching is a technique used to create cutouts or grooves in steel sheets. It involves removing a portion of material from the edge or surface of the sheet, leaving behind a notch. Notching is frequently employed to produce tabs or slots that are useful for assembly purposes. 5. Stamping: Stamping is a technique where a die is pressed into the sheet metal to create a depression or raised feature. This method can be used to create holes, patterns, or embossed designs in steel sheets. Stamping is commonly used for decorative or functional purposes. 6. Shearing: Shearing is a process that employs a sharp blade to cut through the steel sheet, resulting in a straight-edge hole. This technique is typically used for larger holes or straight-line cuts. These are just a few of the numerous sheet metal piercing techniques available for steel sheets. The choice of technique depends on factors such as the desired hole size, shape, precision, speed, and cost-effectiveness.

- Q: What is the difference between a self-color and painted steel sheet?

- A steel sheet that has not been coated or treated with any additional colors or finishes is referred to as a self-color steel sheet. It maintains the steel surface's natural color and appearance, which is typically a metallic gray or silver. Conversely, a painted steel sheet is one that has been coated with a layer of paint or another protective finish. This coating serves multiple purposes, including enhancing the steel sheet's aesthetic appeal, providing additional protection against rust and corrosion, and increasing its durability. The primary distinction between a self-color and painted steel sheet lies in the presence or absence of a coating. While a self-color sheet preserves the raw and natural appearance of the steel, a painted sheet offers a wide array of color options, enabling customization and harmonization with various design schemes. Furthermore, the existence of a paint or protective coating on a steel sheet provides an extra layer of defense against environmental elements such as moisture, chemicals, and UV rays. This helps prevent the steel from corroding or deteriorating over time, thereby extending its lifespan and ensuring its performance in various applications. To summarize, the main contrast between a self-color and painted steel sheet is the presence or absence of a coating. While a self-color sheet retains the natural appearance of steel, a painted sheet offers added protection, customization options, and aesthetic appeal.

- Q: Can the steel sheets be used for outdoor furniture?

- Outdoor furniture can indeed utilize steel sheets. Steel, being a robust and weather-resistant substance, is well-suited for outdoor purposes. It can withstand diverse environmental conditions, including rain, wind, and sunlight, without rapid corrosion or deterioration. Moreover, steel sheets can be manipulated and formed into various furniture styles, offering both practicality and visual allure. Whether it's tables, chairs, benches, or even decorative accents, steel sheets prove to be an exceptional option for outdoor furniture due to their durability, longevity, and adaptability.

- Q: What is the difference between a smooth and expanded metal steel sheet?

- A smooth metal steel sheet has a flat surface with no perforations or raised patterns, while an expanded metal steel sheet has a textured surface with small diamond-shaped openings that are created by stretching the metal.

- Q: Are steel sheets suitable for architectural projects?

- Yes, steel sheets are suitable for architectural projects. Steel is a versatile and durable material that offers several advantages for architectural applications. Firstly, steel sheets are strong and can withstand heavy loads, making them suitable for structural elements in buildings. They have a high strength-to-weight ratio, which allows for the creation of large and open spaces without the need for excessive supporting columns or walls. This makes steel sheets ideal for constructing large atriums, stadiums, or other architectural projects that require expansive interior spaces. Secondly, steel sheets can be easily shaped and formed into various architectural designs. They can be curved, rolled, or bent to create unique and intricate structures. Steel's malleability allows architects and designers to push the boundaries of traditional building designs and create visually stunning and innovative structures. Additionally, steel sheets are resistant to corrosion, weathering, and fire. This makes them suitable for outdoor applications and ensures the longevity of the architectural project. Steel's durability also means that it requires minimal maintenance over its lifespan, resulting in cost savings in the long run. Furthermore, steel sheets are available in a wide range of finishes, textures, and colors, allowing for customization and aesthetic versatility in architectural projects. Whether it is a sleek and modern design or a rustic and industrial look, steel sheets can be tailored to meet the desired aesthetic requirements of the project. Overall, steel sheets are a suitable choice for architectural projects due to their strength, versatility, durability, and aesthetic appeal. Their ability to withstand heavy loads, be shaped into various designs, resist corrosion and fire, and offer customization options make them an excellent material for architects and designers to bring their visions to life.

- Q: What's the good way to connect two Q235 steel bolts? Why?

- A good plan, two plates have a drilled hole, connected by bolts, locking nut.

- Q: Are the steel sheets resistant to chemicals?

- Yes, steel sheets are generally resistant to chemicals due to their inherent durability and corrosion-resistant properties. However, the specific resistance can vary depending on the type of chemical and the grade of steel used. It is advisable to consult with manufacturers or experts to determine the suitability of steel sheets for specific chemical applications.

- Q: What is the typical yield strength of a steel sheet?

- The typical yield strength of a steel sheet can vary depending on the specific grade and thickness of the sheet. However, on average, the yield strength of a steel sheet is typically between 250 and 400 megapascals (MPa).

- Q: Steel plate pile length, adjacent two steel plate pile joints should be staggered what position?

- If the joint in the same position, such as 9+9m then need to stagger joint position,Avoid stress in one position that results in joint fracture and deformation risk.

Send your message to us

Sandwich Panels in High Quality for Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords