Steel Sandwich Color Panel in Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

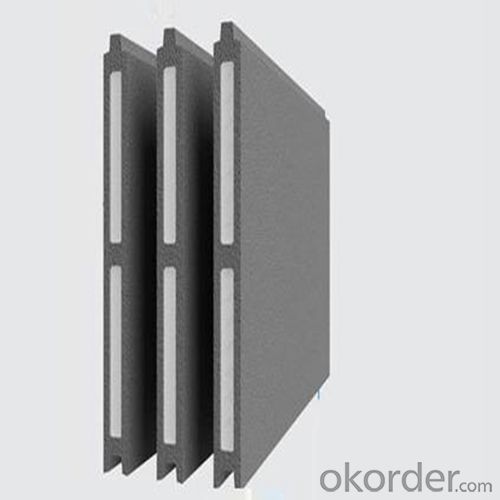

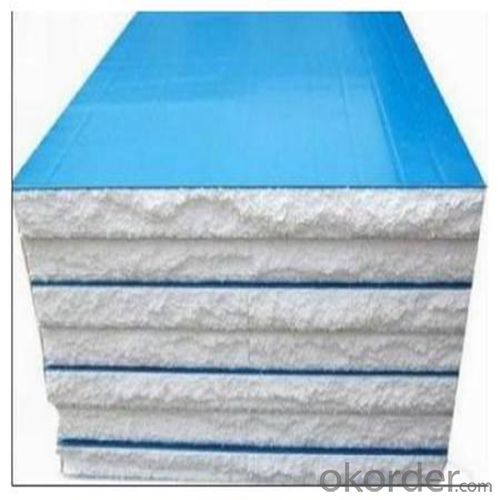

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How long can we receive the product after purchase?

4) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

5).what policy for broken parts?

6)within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: Polyurethane color steel sandwich panels can not be used

- Can be used, but the splicing will be hot and cold bridge phenomenon, the loss of temperature. The best way is to use the local polyurethane sprayer spray foam, so no seams, the best insulation effect.

- Q: Roof 100mmEPS sandwich board how much money a square

- 100MM look at the thickness of steel is generally around 60-85. Need to be able to stand letter me, my Jiangsu

- Q: There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. The burning performance of the material does not meet the requirements of Grade II refractory grade building. Replacement material ~ ~

- Q: Color plate and color steel sandwich panel difference?

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: I just got a polyurethane sandwich board production line, I would like to ask about making money!

- Soft surface or color steel? Color steel is now OK, soft surface of many areas do not let the country, B2 is not up to standard, B1 technology is not mature, and now do the wall decoration board quite fire

- Q: What is the grade of fire resistance of polystyrene sandwich color steel plate?

- This depends on what material is the color of the plate, the manual or mechanism, what is the sandwich

- Q: The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q: So here's the deal, I really need to run the oven cleaner, and I know how much smoke will come out of the oven, and I have a wired smoke alarm directly above the stove (landlord's design not mine). If I cover it with a sandwich bag, will that slow down the chance of it going off or increase the chance? Yes I know to remove the bag directly after the oven cleaner is done for obvious saftey reasons.

- it should slow it down

- Q: Color steel tile foam sandwich board model is how the classification

- Common sandwich panels: foam sandwich panels, rock wool sandwich panels, polyurethane sandwich panels. Common specifications: roof board 980, wall board 950. Common thickness: 50mm, 75mm, 100m.

- Q: Is the interior material of the rock wool sandwich panel fluffy or compact?

- This is related to bulk density. Big enough to be dense, you can knock to listen to its voice.

Send your message to us

Steel Sandwich Color Panel in Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords