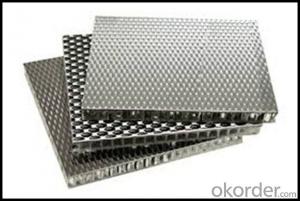

Aluminum Sandwich Panels - Rockwool Sandwich Panel with Color Steel Sheet for Wall and Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Rockwool Sandwich Panel

1.material:steel sheet,rock wool

2.effictive width:950mm

3.lenght:less12m

4.CE with ISO9001

Specifications of our sandwich panel:

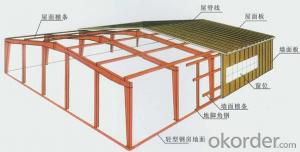

Rockwool sandwich panel is cold rolled into the required profiles from prepainted galvanized

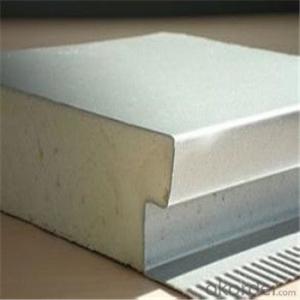

steel sheets or prepainted galvalume steel sheets, which is used as roofing panel in all kinds ofbuildings, such as industrial and civil buildings, warehouse, particular building, inner and outer decorative wall. And there are direct overlapped model, hidden screw model, selflocking model, steel tile sheet, as per your requirement.Itadopts fibrous rock wool as the core material, and color steel plate as its surface layers. The rock wool and two color steel plates are pressed together through the automation of a forming machine and then gluedtogether by a high strength adhesive. Since the color steel plate and the rock wool are noncombustible, the rock wool sandwich panelhas an excellent fireproof property. Our rock wool sandwich panels include roof panels and wall panels. Since they are fireproof, heat insulated and sound insulated, they are widely used to construct roofs and walls of industrial buildings and civil buildings,warehouse, particular building,inner and outer decorative wall. They are especially suitable for use in buildings that require ahigh degree of being fireproof.

Basic information of the rock wool sandwich panel

thickness of interlayer:50/75/100/150mm

thickness of steel sheet :0.3-0.6mm

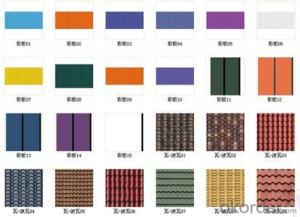

color of back steel:white,red,grey,blue

panel length:up to customers' requirement

effictive width:950mm

density of interlayer:90-150KG/CBM

aplication:widespread use in wall or roof of the factory,supermarkt,storage,etc.

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Or the whole building with the framework of the masonry, or steel structure with masonry Steel structure with the concrete in the economy is very optimistic Just the structure is at least 30% higher than the concrete structure, because at present our steel is relatively small

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- It should be, for example, naphthalene anthracene, and several rings are capable of forming a closed conjugate system. Generally speaking, more than four benzene rings are fused (for example, 1.2-benzo, 3-methyl Anthracene, etc.) are mostly carcinogenic substances, which are mostly anthracene derivatives, the relationship between the mechanism of carcinogenesis and structure is not yet fully understood ...

- Q: Reinforced concrete and metal sandwich board how much difference

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad.

- Q: Color steel sandwich panels and color steel plate What is the difference

- Galvanized steel pipe is divided into cold galvanized steel pipe, hot galvanized steel pipe, cold galvanized steel pipe has been banned, which is also the country to promote the temporary use

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- First, the electricity management: ⒈ temporary electricity must be "" construction site temporary electricity safety technical specifications "JGJ46-88" compilation of electricity construction organization design and development of safe electricity technical measures and electrical fire protection measures. ⒉ temporary electricity engineering drawings must be drawn solely by the electrical engineering and technical personnel, after the approval of the technical person as a temporary basis for construction. ⒊ temporary electricity construction organization design content and steps: ⑴ site exploration, to determine the power line into the total distribution box (cabinet), the distribution of electrical box location and line direction. ⑵ load calculation, select the wire cross-section and electrical type, specifications. ⑶ draw electrical plan, elevation and wiring system diagram.

- Q: Can sandwich panels be used for ticket booths?

- Ticket booths can indeed utilize sandwich panels. Composed of two slim outer layers and a thermal insulating core material, sandwich panels possess a reputation for their robustness, longevity, and energy efficiency. These characteristics render them an excellent selection for diverse construction purposes, including ticket booths. By offering insulation against extreme temperatures, reducing noise, and providing fire resistance, sandwich panels offer essential attributes for ticket booths. Furthermore, their lightweight nature allows for effortless transportation and installation. They can be tailor-made to accommodate specific design specifications and require minimal maintenance. Consequently, sandwich panels emerge as a fitting and pragmatic choice for ticket booths.

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: The stove is dedicated to the plastic used for plastic paper

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, maintenance-free features, has been widely used Caigang sandwich panels Is the current building materials in a common product, not only can be a good flame retardant and environmentally friendly and efficient. Caigang sandwich board has two layers of metal panels and the middle of the polymer core insulation from the suppression. With the installation is simple, light and efficient light and efficient features. And the filling system used to close the molecular structure of the closed, you can put an end to the condensation of water vapor. The tile is used for the panel for the wall

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- the bottom of each pole should be set at the bottom or pad

Send your message to us

Aluminum Sandwich Panels - Rockwool Sandwich Panel with Color Steel Sheet for Wall and Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords