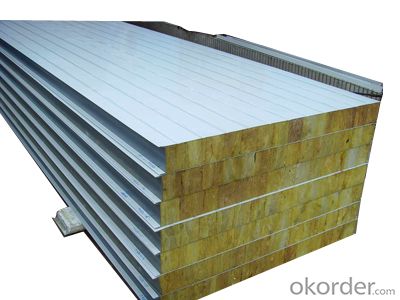

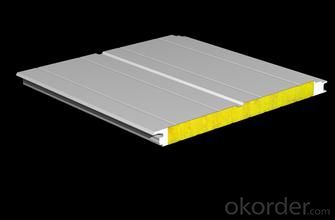

Fireproof Color Steel Glass Wool Sandwich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panel is a structure made of three layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

Specifications:

Light weight

Excellent sound insulation and heat insulation

Easy installation

Fireproof and water proof

Long life:10-15years

Beautiful appearance

Size:

Item Data

Effective Width: 1150MM/960MM/950MM

Length: Can be customized

Materials: Glass Wool, Color steel sheet

Structure: Upper and lower layer: Color steel sheet

Middle: Glass Wool

Thickness of color steel sheet: 0.3-0.8MM

Colors: Blue, white or according to your requirements

- Q: What is the typical thickness tolerance of a steel sheet?

- Depending on the specific industry and application requirements, the thickness tolerance of a steel sheet can vary. In general, a standard steel sheet may have a thickness tolerance ranging from +/- 0.001 inches to +/- 0.010 inches. This implies that the actual thickness of the sheet can fall within these tolerances. The determination of the tolerance level is influenced by factors including the manufacturing process, the intended use of the sheet, and the desired level of precision. It is worth mentioning that certain industries or applications may necessitate more precise tolerances, particularly when dimensional accuracy is of utmost importance.

- Q: Are steel sheets suitable for water storage tanks?

- Yes, steel sheets are suitable for water storage tanks. Steel is a durable and strong material that can withstand the weight and pressure of water. It is also resistant to corrosion when properly coated, ensuring the water remains safe and uncontaminated.

- Q: How do you cut a steel sheet?

- To cut a steel sheet, you will need to use the appropriate tools and techniques. Here are a few common methods: 1. Power tools: The most common power tool used for cutting steel sheets is an angle grinder equipped with a cutting disc. Make sure to wear safety goggles and gloves while operating the grinder. Mark the cutting line on the sheet using a marker or chalk, then slowly and steadily guide the grinder along the marked line to cut through the steel. 2. Shears: If you are cutting a thin steel sheet, you can use manual or electric shears. These tools have a scissor-like cutting mechanism specifically designed for cutting metal. Place the steel sheet between the blades of the shears, aligning the cutting line with the blades, and apply steady pressure to cut through the sheet. 3. Plasma cutting: This method is best suited for thicker steel sheets. Plasma cutting involves using a high-velocity jet of ionized gas (plasma) to melt and sever the metal. It requires specialized equipment, such as a plasma cutter, which uses an electric arc to create the plasma jet. 4. Waterjet cutting: Another effective method for cutting steel sheets is waterjet cutting. It uses a high-pressure jet of water mixed with an abrasive substance (such as garnet) to cut through the metal. This technique is ideal for complex shapes and precise cuts, but it requires specialized machinery. Before attempting to cut a steel sheet, always prioritize safety. Wear appropriate protective gear, such as safety glasses, gloves, and a face shield if necessary. Additionally, ensure that you are working in a well-ventilated area to avoid inhaling any fumes or particles generated during the cutting process.

- Q: Can steel sheets be used for agricultural equipment?

- Yes, steel sheets can be used for agricultural equipment. Steel is a durable and strong material that can withstand the harsh conditions and heavy use associated with agricultural activities. It is commonly used in the construction of farming equipment such as plows, harrows, and seeders. Steel sheets can also be shaped and welded into various forms to meet specific agricultural needs.

- Q: What is the average lifespan of a steel sheet roof?

- The average lifespan of a steel sheet roof can vary depending on various factors such as the quality of the steel, installation techniques, climate conditions, and maintenance. However, a well-maintained steel sheet roof can typically last between 30 to 50 years or even longer.

- Q: Can steel sheets be used for water treatment facilities?

- Yes, steel sheets can be used for water treatment facilities. Steel is a commonly used material in the construction of water treatment facilities due to its durability, strength, and resistance to corrosion. It is often employed in the fabrication of tanks, pipelines, and other infrastructure components used in water treatment processes.

- Q: Are steel sheets non-magnetic?

- No, steel sheets are generally magnetic.

- Q: Can steel sheets be used for elevator manufacturing?

- Indeed, elevator manufacturing can involve the utilization of steel sheets. Owing to its robustness, endurance, and ability to withstand fire and corrosion, steel serves as a frequently employed substance in the construction of elevators. For the fabrication of elevator cabin walls, floors, and doors, steel sheets are commonly employed. In addition, steel finds application in the structural framework and support constituents of the elevator system. The inclusion of steel sheets in elevator manufacturing ensures steadfastness, security, and durability, rendering it a trustworthy option for vertical transportation.

- Q: What is the difference between Q235A steel and Q235B steel?

- Secondly, in the tensile and impact experiments, the material is Q235A steel, no impact test, the material is Q235B steel to do the normal temperature impact test, V notch. Relatively speaking, the mechanical properties of materials Q235B steel is much better than the material of Q235A steel.

- Q: What are the different types of steel sheet finishes?

- Various purposes are served by several different types of steel sheet finishes, each providing unique aesthetics. Some common types include: 1. Hot Rolled: Achieved by heating the steel sheet above its recrystallization temperature and rolling it to the desired thickness. It has a rough and textured surface, suitable for applications where appearance is not a priority. 2. Cold Rolled: After hot rolling, the steel sheet is passed through rollers at room temperature to achieve a smooth and polished finish. Cold rolled finishes are often used in applications that require a superior surface finish, such as automotive panels or appliances. 3. Galvanized: In this process, the steel sheet is coated with a layer of zinc to provide corrosion resistance. The zinc coating also gives the sheet a shiny and reflective appearance. Galvanized finishes are commonly used in outdoor applications to protect against rust and harsh weather conditions. 4. Stainless Steel: Achieved by adding chromium to the steel sheet, providing excellent corrosion resistance and a sleek, reflective surface. Stainless steel finishes are widely used in kitchen appliances, architectural applications, and medical equipment, where hygiene and durability are essential. 5. Coated Finishes: Steel sheets can be coated with various materials, like paint, epoxy, or polymer, to enhance appearance or provide additional protection. Coated finishes can be customized to meet specific requirements, such as color or texture, and are often used in architectural and decorative applications. 6. Brushed: Obtained by brushing the steel sheet with abrasive material, creating a textured and matte surface. Brushed finishes are commonly used in interior design and furniture manufacturing, where a contemporary and stylish appearance is desired. These examples represent just a few of the available steel sheet finishes. The choice of finish depends on the specific requirements of the application, such as corrosion resistance, aesthetic appeal, or surface texture.

Send your message to us

Fireproof Color Steel Glass Wool Sandwich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords