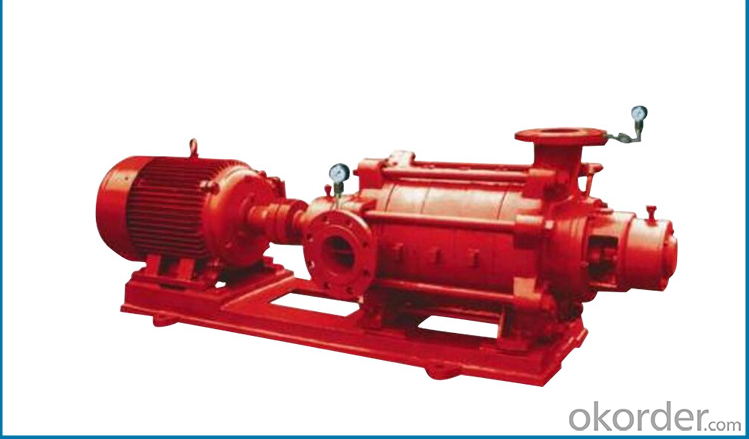

Fire Pump Cast Iron High Flow High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Introduction

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product specification

Electric water pump adopts special combination structure design. They are generally

applied to transport pure water or the liquids with physical and chemical properties similar to pure

water, and the maximum allowed medium temperature is 80°C. Especially suitable for

pressurization of water supply network. The advantages are small size, easy installation, no

vibration and low noise. The shaft sealing adopts mechanical seal.Pump can transport

liquids of Maximum 120°C. Type IHG pump could be used in chemical process.

Application

Mainly apply to delivery sewage water ,waster water and rain water contains solids and

fibres:

*municipal project

*building construction

*residential area

*industrial sewage treatment

*eviroment protect

*mining

Features

1. Hydraulic design with wide flow-path non-clogged structure ,allowed fibres(3 times

length of inlet diameter),particles(30% size of inlet diameter )

2. Excellent design,high efficiency and energy saving .

3. Double mechnical seals in series,made of hard alloy corrosive proof silicon

carbide,which is durable and .wearable ,that enable pump safely operation for more

than 8000 hours continous.

4. Compact structure, small volume, easy moved and conveniently mounted , no need build

pump house, greatly reduct the cost.

pump superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Pictures show

Transportation

- Q: Fire pump and spray pump requires a preparation, 2 sets of the same pump requires mutual investment, when the main pump failure of backup pump automatically put into use. 1: so what is the throwing device: 2: where is the device installed? It should be in the water pump control box. 3: what is the principle of mutual voting? Detailed description

- You can refer to the DCL and DCS microcomputer access control system, you can achieve the purpose of remote control. Specific installation methods can be found in local instrument engineering inquiries.

- Q: What is the function of open circulating water pump and shutdown in thermal power plant?

- According to the water quality difference, the purpose is to provide the corresponding cooling water, for the system oil cooler, machine seal and other cooling. Open water directly from the circulating water pipe to use, the pump is delivered to the host, the small machine oil cooler, water quality is not very high, the circulating water drainage to the back pipe, water through the water filter filter impurities. The closed water takes the self closing water tank, which is used for removing salt water. General supply pumps, water pumps, sealing cooling water, condensate pumps, sealing water, generator, hydrogen cooler and other requirements of good water quality system, closed water self circulation, and through the cooler and open water circulating water heat exchange.

- Q: Im changing my water pump and it has a pully that the belt gos on in front of it and the pully has 1 big bolt in the middle of it and like 4 small ones around it and when i try to undo the bolts the pully turns and im not quite the mechanic but i do know that the pully has to come off 1st so how do i take out the bolts without the pully turning???? and yes the belt is off and battery id disconnected and the car is not hot it hasnt ran in days. and it has a 3.4 v6

- For the best answers, search on this site https://shorturl.im/awNHT Did you hit up both bleeders? Run the car until the thermostat opens. You'll know when because the cooling fan will cycle on. With the car running, and the Rad cap off, start with the bleeder near the thermostat housing (RH side as you're looking at the motor from the front.) Leave it open until you have steady stream of coolant flowing. Close, and move to the bleeder on the left. It's on the metal tubing above the water pump. Same thing, open until coolant flows. Close bleeder, then run the engine up manually at the throttle body. Keep adding coolant to the radiator untill it's topped off with no bubbles coming out. Cap the radiator before letting off the gas. Fill the resevoir, to the full hot line or a little over. Any random small bubble with make their way to the res, being replaced by fluid.

- Q: I have taken off the fan, and radiator, and ect, and i'm down to this silver circle thing-the fan clutch i believe and black circualr piece that connects to the actual water pump. I need help getting the quot;fan clutchoff. I tried using a wrench and wrenching on this peice between that and the black piece, but i cant stop the black piece from moving. I tried this site called pelican or w.e, but they dont tell u how to do that. I'm stuck, plz help!

- Usually there is a notch, slot, or hole in the housing into which you can insert a screw driver or punch to prevent it from turning and then you can use the wrench on the bolts.

- Q: I found a small submersible water pump for pond decorations or birdbaths in my garage. It's about the size of three decks of cards stacked on top of each other. Would there be any harm/benefit of putting this into a 55 gal fw community tank?

- well it depends, do you have any small fish? and how is the water cycled in the pump? it needs to be protected so that fish dnt obviously get sucked. before you add it in tho need it submerged in a bucket of water and add several teaspoons of salt; that will kill all the bacteria that may have grown on and inside the pump. leave it in there for minimum 24 hours (just to be sure).

- Q: Water pump for 98 Venture?

- To replace the water pump on the 3.4L Venture calls for 1.3 hours labor (about $130) and the pump is about $30 and it is a good idea to replace the thermostat and flush the cooling system to get maximum life out of the pump and your cooling system about $100 so you would be looking at about $350

- Q: I'm going to be purchasing a laboratory distillation kit here pretty soon, the kit includes everything I need for the setup but the condenser requires a water pump to circulate cold water around the coils. What kind of pump would you recommend for this purpose?

- The only thing you might need a pump for is if you are distilling/refluxing something and it is not all condensing before it reaches the end/top of the tube, resulting in vapor escaping. In that case you would use a bucket of ice water with a submersible pump.

- Q: i dont think that the water pump is out. i have a 88 evinrude outboard and the other day i noticed that the water was barley trickling out the hose. then it just stopped coming out the hose. it still comes out of the exhaust just fine. the motor is not get hot. is it ok if it still comes out the exhaust/ i will attemp to run a wire up in the hose to see if it is clogged later today. what do yous think

- I think you might want to replace the water pump impeller.

- Q: I have two water well good water but not a lot of water .is it possible to hook two pumps up to one holding tank . if so how do I hook them up

- It should be possible, it would be best if both pumps were identical. They should be hooked up in parallel to increase flow rate.

- Q: I've never had overheating problems before, (although the heating itself never worked great) but today the gauge suddenly spiked while driving at about 50mph. I pulled over and steam was coming off the engine and the cooland tank was bubbling. The coolant was low, but not empty. I put some water in the coolant tank, let the engine cool and drove to a gas station where I got some coolant which I mixed with the water in the coolant tank. That didn't seem to help any. Even after letting the engine cool completely, it spikes after less than five minutes of driving. The radiator and both top and bottom hoses are equally hot. When I tried to start the engine with the radiator cap off, cooland shoots up out the top. The fans are working propely and there is no debris on the front of the radiator. So I'm sort of at a loss. Also, I've had some trouble starting since the problem.

- You need head gaskets. Compression from the cylinders is getting into the cooling system.

Send your message to us

Fire Pump Cast Iron High Flow High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords