Cast Iron Portable Fire Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

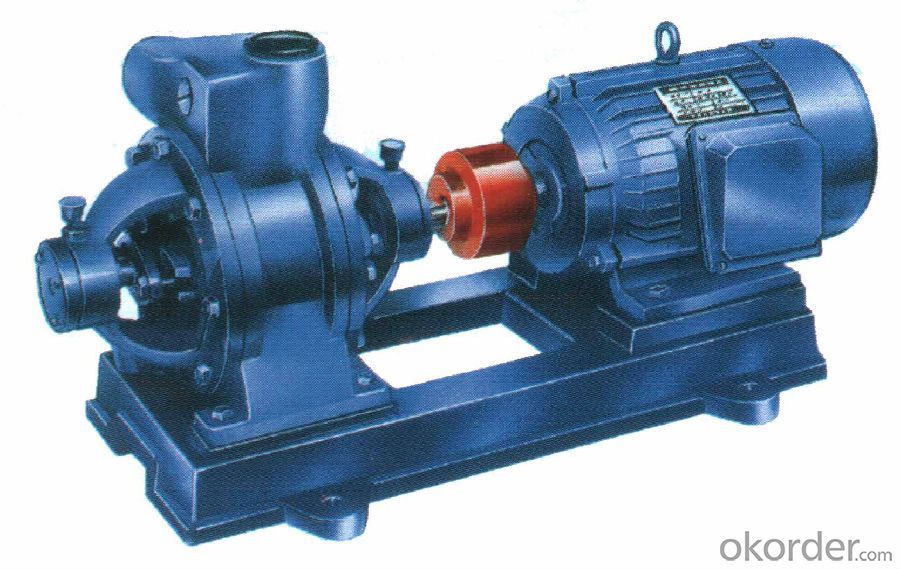

Cast Iron Portable Fire Pump High Quality

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Cast Iron Portable Fire Pump High Quality

| Capacity: | 20-200L/s |

| Head: | 0.3-1.28MPa |

| Speed: | 2900r/min、1450r/min |

| Power of fitted motor: | 0.75-250kW |

| Inler diameter: | 25-300mm(1"-12") |

Application Range of Cast Iron Portable Fire Pump High Quality

It is mainly used for the water supply for the fixed firefighting system of both industrial and civil building

fire hydrant fire-extinguishing system,

automatic spraying,

fire-extinguishing system.

Cast Iron Portable Fire Pump High Quality Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Picture Show

Why choose us

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: What does 'MCL' Unit stands for water pump. How can convert this Meter head of the pump. For example : 50 MCL to ------- MTR HEAD. What is the formula?

- This Site Might Help You. RE: What does 'MCL' Unit stands for water pump.? What does 'MCL' Unit stands for water pump. How can convert this Meter head of the pump. For example : 50 MCL to ------- MTR HEAD. What is the formula?

- Q: What is the water pump population pre rotation, what harm?

- Is the entrance of water flow in the formation of complex turbulent flow, flow direction, shock, vibration, easy to damage the front entrance device, such as vane impeller, shaft sleeve, sealing element.

- Q: 300M head of 11 stage centrifugal pump with 22KW motor, empty (not water) current of 13A, the water into the pump, current up to 44A, open the outlet valve of the current rising to 100A, immediately shut the gate current is up to 170A, the motor stop. Without any problems, not on the impeller pump shaft is not clean the shell the balance sheet, no wear, bearing normal.

- (1) the influence of the basic installation on the equipment.The quality of equipment foundation installation has great influence on the quality of equipment operation. Iron pad placed properly, causing around the foot bolt hanging device, in alignment and fastening process for iron pad hanging, tighten anchor bolts will cause deformation of crosshead slide in the crankcase, the cross head is blocked in the operation of reciprocating load increases when the chute.W5 type reciprocating vacuum pump in the structural design of the cylinder body is cylinder, and the piston, intake and exhaust valve after the heavy weight in the foundation design without considering the cylinder support or hanger, the cylinder will be in a suspended state, because the weight of the crankcase cylinder will cause deformation of the cylinder and slide and slide the concentric degree of difference, so that the cross head is blocked in the slideway and the piston reciprocating operation is blocked during the reciprocating motion in the cylinder caused by the increase of the load.According to the above analysis, inspection found that the vacuum pump end of the cylinder body is slightly lower than the end of the crankcase, cylinder pad iron is low, deformation of crosshead guide foot bolts, the cross head caused by load increases in the slideway and the piston in the cylinder reciprocating operation is blocked, this is one of the reasons causing motor overheating.(2) cylinder and valve coking;The influence of process, cylinder and valve of reciprocating pump is easy to coke, Coke will cause the piston cylinder and piston in reciprocating cylinder operation when the load increases the valve is blocked; coking will cause poor exhaust, the valve closed lax, increasing load, low vacuum degree; clearance at the cylinder piston striking the cylinder will cause coke it will increase the load of cylinder, valve has found the phenomenon of coking, which is mainly caused by the low degree of vacuum.

- Q: how do you change the water pump

- When you change the timing belt you as well change the water pump as well. If you take it to anyone for timing belt change they will ask you if you want to change water pump because its convenient to change it out at that time. But if you dont have any knowledge how to work with the timing dont mess with it take it to someone who is knows what there doing because paying couple hundred dollars is better then paying thousands for engine rebuild or new engine.

- Q: 2 pumps in parallel, lift the same, the pump head is not stacked; 2 pumps in series, the same flow, pump head is not superimposed?.

- 2 pumps parallel, lift the same, pump head is not stacked?;Answer: the head can not be superimposed, that is, a lift and a pump, but the pumping speed (flow) is two times a taiwan.2 pumps in series, the same flow, pump head is not stacked?.Answer: the head can be superimposed, that is, the pump head is two times as much as a pump, but the pump speed is the same as that of a pump.

- Q: What are the new regulations in the design of main and auxiliary water bin and water pump room in coal mine?

- The main water bin must have a main bin and an auxiliary warehouse. When a sump is cleaned, another water tank can be used normally.When the normal water inflow is below 1000m3/h, the effective capacity of the main water tank should be able to accommodate the normal discharge of 8h.The effective capacity of the main water bin can be calculated by pressing type in the mine where the normal water inflow is greater than 1000m3/h:V = 2 (Q+3000)Effective capacity of V-- main water bin in type m3;Q-- mine hourly normal water inflow, m3.However, the total effective capacity of the main water storage tanks shall not be less than the normal water inflow of 4h.The effective capacity of the water tank in the mining area shall be able to accommodate the normal water inflow in the 4H mining area.There is a big difference between the maximum water inflow and the normal water inflow in the mine. The drainage capacity and the water storage capacity should be specially designed.The water inlet chamber should be set up. A sedimentation tank shall be provided for the filling of water sand, hydraulic coal mining and other gushing water with a large amount of impurities. The water storage capacity of short positions must often remain above 50% of total capacity.

- Q: 22KW pump motor direct start circuit breaker and contactor size? Concrete calculation method

- Strictly speaking, eleven kilowatts or more is not allowed to start directly

- Q: Why does the water pump leak?

- The sealing ring is invalid

- Q: Do you need a stop valve for the pump at home?

- It is better to connect with the pump. If it is a self suction pump, it can not be connected, but when it is pumped, it does not immediately have water, and the submersible pump is not necessaryMy home is a self suction pump, fully automatic control, I took the check valve, in the pump suction port position is very good, as long as it has started, there will be water out

- Q: For a basement water pump that controls the toilet, shower and sink--- does it always have to stay plugged in and running??? I heard it make a weird noise and shut it off immediately.. Any help appreciated!!!

- Most of the time when you use water a large amount the pump will come but should shut off after a reasonable amount of time. When the set pressure is achieved it will shut off. And when the pressure drops it will turn on and the pressure will drop when using water.

Send your message to us

Cast Iron Portable Fire Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords