Cast Iron Control Panel Fire Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

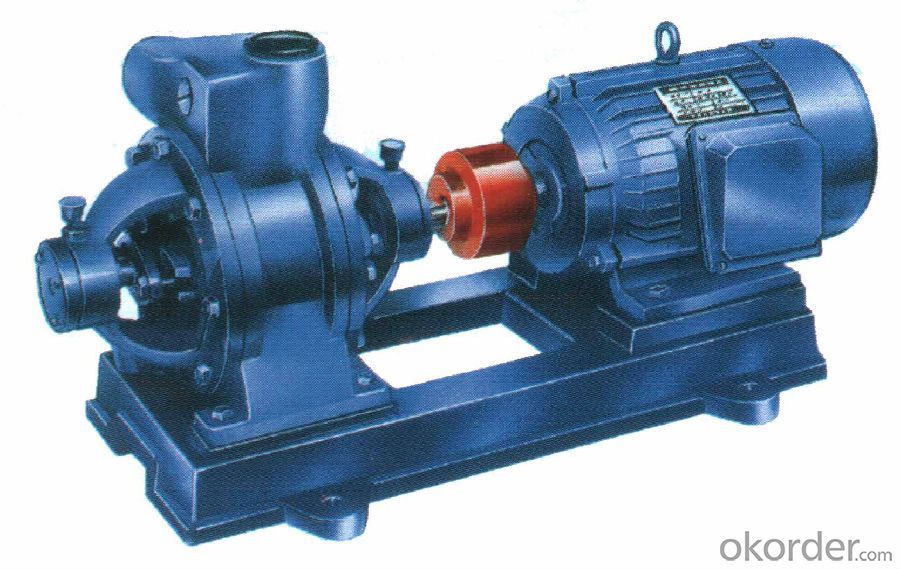

Cast Iron Control Panel Fire Pump High Quality

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Cast Iron Control Panel Fire Pump High Quality

| Capacity: | 20-200L/s |

| Head: | 0.3-1.28MPa |

| Speed: | 2900r/min、1450r/min |

| Power of fitted motor: | 0.75-250kW |

| Inler diameter: | 25-300mm(1"-12") |

Application Range of Cast Iron Control Panel Fire Pump High Quality

It is mainly used for the water supply for the fixed firefighting system of both industrial and civil building

fire hydrant fire-extinguishing system,

automatic spraying,

fire-extinguishing system.

Cast Iron Control Panel Fire Pump High Quality Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Picture Show

Why choose us

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: My water pump is losing pressure slowly even though no water is being used. Your help is appreciated. Thank you.

- Water Pump Loses Pressure

- Q: 1998 Honda civic water pump plastic or metal inside (OEM)?

- Water pumps are metal including the frame, the water pulley, and the fins on the other side. Plastic fins would not be ideal as it would spin constantly and come in contact with hot coolant for the duration your engine is on. Eventually, it would soften, bend and become insufficient in pushing and circulating coolant throughout your engine. Hope this helps!

- Q: I'm building a 79 SBC (old style) 350 and have a new stock water pump...what hose and where does it go from the top of the water pump to wherever? Heater hose? Or can I just leave it plugged. No A/C I just need a heater/defroster, etc...

- New thermostat, yet have you ever tried a decrease temp thermostat? Our RV 479 CI used to run a million/2 way up and three/4 in end/bypass and close to the pink line up mountain roads. I placed a decrease thermostat and it runs a million/4 and <a million/2 end/bypass. severe temps are dry out electric powered cord rubber insulators and that i have had to replace diverse the ignition wires. also it is frustrating to crank reason you have become vapor lock. The gas contained in the gas is so warm is turns to vapor and the gas pump can no longer longer suck gas because it isn't reliable adequate to suck vapor, in ordinary words liquid gas. if so, flooded start up tactics might want to artwork. floor the gas, shop it floored and crank the starter. Pump like loopy also, yet shop you foot in truth floored. it would want to start up.

- Q: water pump

- Flow? Head? suction pressure? Type of pump if that matters to you? You'll get better suggestions if you provide as much information as is relevant.

- Q: i have changed water pump,radiator and thermotast and it still overheat

- (In addition to the above suggestions) Are the hoses good? Old hoses can collapse, blocking water flow. They should have been changed with the radiator, but not everyone does. Has the radiator fan been checked out to be sure it's working properly? If the fan isn't working properly, enough air might not get through to cool it down properly. Is it actually boiling over, or is the temp gage just showing it hot? I ask because it could be a faulty temp sensor. I'll assume that there's no debris between the radiator and condenser since the radiator has been changed out already. This should also mean that nothing is in front of the condenser blocking airflow.

- Q: I know that the water pump is belt driven, so it would be easy to connect it to my bicycle. What I am wondering is if I can pedal fast enough to make it work. Does anyone know how fast I would need to pedal to operate the pump?

- Pretty fast. Engines operate at 600-6000 rpm and the pump pulley is a little smaller than the drive pulley, so it is spinning even faster. That said, 600 rpm is plenty fast enough. You can attain that easily by applying pulley to rear tire tread, raising tire off ground and pedaling. To apply bike chain to pulley would give a disappointing water flow.

- Q: I think the water pump in my Oceanic BioCube is going up. What is a good brand that would be compatible? It is 29 gallons. Thanks.

- If okorder or just your local pet store and see if you can't buy a pump with a similar/same output.

- Q: Trying to replace my water pump and was told labor would cost $90 for an 06 impala 3.9L I don't know if it's reasonable for the amount of work.

- way too cheap , they are obviously going to stack the price on extras and ancillaries, belts, coolant, thermostat etc

- Q: What is the reason that the water supply of pump is getting smaller?

- What kind of pump is it, home pump or factory pump? Single stage impeller or multistage impeller? Vertical or horizontal? Is it single suction or double suction? Different structure of the day pump has different causes of failure. But in general, there are several aspects: 1., the water inlet is small, the inlet pipe is blocked; 2., the blade is worn or broken; 3., the motor speed drops; 4., sealing serious leakage; 5., cavitation phenomenon.

- Q: i want to change the water pump on my on a 70 hp (70C) nissan outboard motor and i never pulled a lower unit, not sure what to expect thanks for any help

- ((( get a manual))) like has been said ..but here is some genneral proceedure::::// after loosening the gear case at the cavitation plate ,,,, pull it away from the leg about half an inch and acsess the gear linkage shift rod and undo the conecting nut,, then pull the gear housing away --- ((( when you reinstal it you will have to turn the propelor by hand to push the drive shaft spline into place ))) --<- then you will have the pump housing on the gear caseing .. just pull it off the shaft retaining the small key way that turns the impelor.. ::::::: replace the impelor and push the pump housing down over the impelor..,,,, as you push it down,, turn the propelor by hand so the shaft rotates and make the fins on the impellor bend away from the shaft ,,, make sure the shaft is turning the correct way ,,with the gear in foward ,, turn the propelor so it drives foward or if in reverse turn the propelor so its driving backwards ,,, there should be a gasket between the pump housing and the gear caseing,, if not ,, use some silastic ,,, ((check the manual)) <<<<<<<<<<<<

Send your message to us

Cast Iron Control Panel Fire Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords