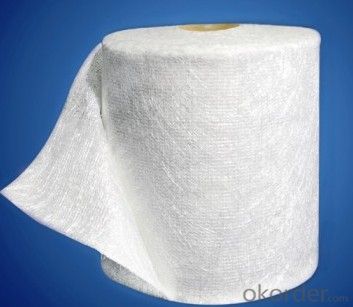

Fabric for Fiberglass Speaker Box - Fiber Glass Stitched Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

| (g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Are fiberglass fabrics resistant to solvents or cleaning agents?

- Yes, fiberglass fabrics are generally resistant to solvents and cleaning agents.

- Q: How does fiberglass fabric handle moisture?

- Fiberglass fabric has excellent resistance to moisture and is considered to be highly water-resistant. Due to its composition of woven glass fibers, it does not absorb water and is unaffected by moisture or humidity. This makes fiberglass fabric ideal for applications where exposure to moisture is expected, such as boat hulls, outdoor furniture, and building materials. Additionally, fiberglass fabric does not promote the growth of mold or mildew, further enhancing its ability to handle moisture.

- Q: How does fiberglass fabric perform in shear strength?

- Fiberglass fabric has excellent shear strength performance. Due to its composition of intertwined glass fibers, it possesses strong resistance to forces applied parallel to its surface. The interlocking fibers create a strong and rigid structure that allows it to withstand shear stresses and prevent deformation or failure. This makes fiberglass fabric highly suitable for applications where shear strength is important, such as in the construction of lightweight, high-strength composites, reinforcement of concrete, and the manufacturing of various industrial products. Additionally, fiberglass fabric's shear strength is not significantly affected by exposure to moisture, chemicals, or high temperatures, making it a durable and reliable material for a wide range of applications.

- Q: What is waterproof, one cloth, four coated?

- 4 times the coating (polyurethane or modified asphalt waterproof coating, etc.), in the middle of laying a matrix reinforced material (glass fiber cloth or polyester cloth).

- Q: Can fiberglass fabric be used for making gaskets or seals?

- Indeed, the utilization of fiberglass fabric is viable for the production of gaskets and seals. Renowned for its superior potency and durability, fiberglass fabric emerges as an optimal material selection for applications pertaining to gaskets and seals. Its capacity to endure elevated temperatures, withstand chemical substances, and provide insulation properties renders it suitable for deployment across a diverse range of sectors, encompassing automotive, aerospace, and manufacturing. Moreover, the versatility of fiberglass fabric permits effortless cutting and molding into various shapes and sizes, tailored to meet the specific requirements of individual gaskets or seals. Overall, fiberglass fabric showcases commendable sealing capabilities, thereby establishing itself as a dependable option for fabricating gaskets and seals.

- Q: How does fiberglass fabric handle UV exposure?

- Fiberglass fabric is known for its excellent resistance to UV exposure. The material is made by weaving together fine strands of glass, which are inherently resistant to damage from the sun's ultraviolet rays. This means that fiberglass fabric can withstand prolonged exposure to sunlight without experiencing significant degradation or weakening. The glass fibers in fiberglass fabric are typically coated with a protective layer, such as a resin or polymer, which further enhances its UV resistance. This coating acts as a barrier, shielding the glass fibers from direct contact with the UV rays and preventing any potential damage. Additionally, the coating helps to maintain the fabric's strength and integrity over time, even when exposed to harsh sunlight. As a result of its UV resistance, fiberglass fabric is commonly used in outdoor applications where exposure to sunlight is expected. It is often used in the construction industry for roofing, insulation, and cladding, as well as in the automotive sector for various exterior components. The fabric's ability to withstand UV exposure makes it a durable and long-lasting choice for these applications. However, it is important to note that while fiberglass fabric is highly resistant to UV rays, it is not completely immune to their effects. Prolonged and intense exposure to sunlight can eventually lead to some minor degradation, such as fading or discoloration. This is a natural process that occurs over an extended period of time and does not significantly impact the fabric's structural integrity or performance. To maintain the longevity of fiberglass fabric when exposed to UV rays, it is recommended to apply a protective coating or finish specifically designed for UV protection. Regular cleaning and maintenance can also help to prolong the fabric's lifespan and ensure its continued resistance to UV exposure.

- Q: Can fiberglass fabrics be used for insulation in pipelines?

- Yes, fiberglass fabrics can be used for insulation in pipelines. They are commonly used due to their excellent thermal insulation properties, high temperature resistance, and durability.

- Q: How is fiberglass fabric used in the production of electrical cables?

- Due to its exceptional insulation properties, fiberglass fabric is commonly incorporated in the manufacturing process of electrical cables. The fabric is composed of interwoven glass fibers, which possess remarkable electrical resistance. When utilized in electrical cables, fiberglass fabric functions as a protective insulating layer, shielding the conductive wires against adverse external elements such as moisture, heat, and physical harm. Throughout the production procedure of electrical cables, it is customary to saturate the fiberglass fabric with a resin or polymer. This infusion further heightens its insulation capabilities and guarantees its stability and endurance. Subsequently, the impregnated fabric is enveloped around the conductive wires, forming a safeguarding layer that aids in preventing electrical leakage and short circuits. Furthermore, fiberglass fabric exhibits exceptional resistance to fire, rendering it an optimal material for electrical cables. In the event of a fire outbreak, the fabric acts as a barricade, effectively impeding the propagation of flames along the cable, thereby diminishing the likelihood of additional harm or accidents. In conjunction with its insulation and fire-resistant properties, fiberglass fabric also imparts mechanical strength and flexibility to electrical cables. Its interlaced structure fortifies the cable's tensile strength, enabling it to endure tension and bending without succumbing to breakage or loss of functionality. All in all, the utilization of fiberglass fabric in the production of electrical cables ensures the dependable and secure transmission of electrical currents while concurrently safeguarding the cables and their surrounding environment from potential hazards.

- Q: What are the differences in the quality and performance of domestic glass fiber cloth and imported fiberglass fabric?

- Imported glass fiber: it is made up of two layers of non-woven fabric and a layer of glass fiber. The layers are clear and the filter layer is thin. It is easy to break the water in the oil, and the accuracy is generally 1 - 25 microns

- Q: Is fiberglass fabric resistant to rot and decay?

- Yes, fiberglass fabric is resistant to rot and decay.

Send your message to us

Fabric for Fiberglass Speaker Box - Fiber Glass Stitched Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords