Extra Clear Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

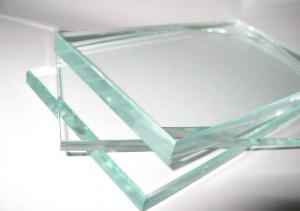

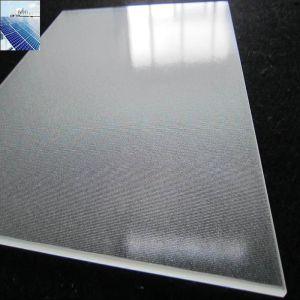

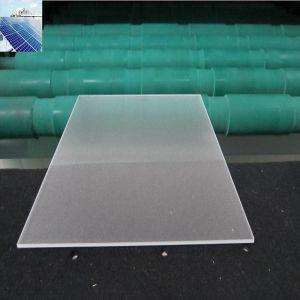

Extra Clear Glass is a kind of low iron and transparent glass with high light transmittance(>91%), also called low iron glass. It is a high-quality, multifunctional and newly high-end glass. Being crystal clear and elegant, it is crowned as "crystal prince" of the glass family.

Features of Extra Clear Glass:

1. High claity: 6% higher visible light transmittace than ordinary clear glass;

2. Nobility and elegance:with the unique lavender edges , it has the feeling of the the sapphire against the sunshine.

3. Safety: No detonating impurities/metallic and no spontaneous detonation.

4. Low UV transmittance and Environmentally friendly products: can effectively prevent UV radiation and protect interior items from fading and aging.

5. CE/SGS/REACH Certificates.

Specifications of Extra Clear Glass:

Thickness: 2- 25mm

Size:

920*1016mm

3660*18000mm

Customized Sizes

Applications of Extra Clear Glass:

Ultra Clear Glass has been widely used in various fields:

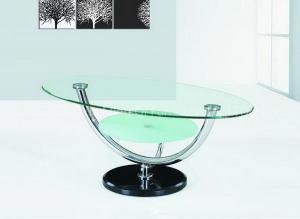

1. Interior and Exterior Decorations of Advanced Buildings: like curtain walls, glass doors of the lobby, transparent roof, glass ribs, glass suspended ceilings, partitions, walls, guard rails, stairs, etc.

2. Exhibition Hall and Showcase: in museum, exhibition hall, jewelry shop, clothing store, etc.

3. Home Appliances: as the screen protector of plasma TV, high-end visual refrigerator door, high-grade microwave oven panel, refrigerator cover, range hood cover, etc.

4. High-end Arts and Crafts, Lamps, etc.

5. Furniture and Bathroom Products.

- Q: What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q: The glass door in the shower room is too heavy. What material can be substituted, which is as transparent as glass but lighter than glass?

- You can use the transparent acrylic plate, acrylic plexiglass (acrylic) history in the early 20s, Solomon ha company first invented a new method of acrylic plate used for the polymerization of MMA, the board later called "Oroglas/Plexiglas"

- Q: What is the difference between acrylic board, lotus board, organic board and PVC board?

- PVC board is a kind of vacuum plastic film. It is used in the surface packing of various panels, so it is also called decorative film and adhesive film. It is applied to many fields such as building materials, packaging, medicine and so on. Among them, the building materials industry accounted for the largest proportion, 60%, followed by the packaging industry, as well as other small range of applications. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foaming board.

- Q: Aluminum alloy window glass tape, how fast loading?

- The inside mounting method is opposite to the outside installation method, that is, the operator stands on the indoor floor or indoor high stool to install the glass of the aluminum alloy door and window. In the first window in the fixed slot lateral seal, safety glass, positioning, and then fixed to the inside of the notch is injected in the cavity joint sealant fixed, which is dry and wet two kinds of material mixed use practices.

- Q: Is the price of glass raw material the biggest proportion of quartz?

- The main are: quartz sand. And soda ash.

- Q: Does fiberglass contain formaldehyde? I'm a hair salon. Buy a glass fiber reinforced plastic shampoo bed, there is always a pungent smell of the body, there is no harm to it, including formaldehyde free

- Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. The main raw materials of glass fiber reinforced plastics are resin, curing agent and glass fiber. Glass fiber is not toxic, but contact the skin will be itching. And resin and curing agent have certain harm to human body, especially curing agent, if it is the curing agent of aromatic amine, that is relatively harmful to human body.

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- The production of glass bottles industry, its raw materials are stone powder, quartz sand, soda ash, waste glass and coalA variety of materials used in the preparation of glass batch, collectively referred to as glass raw materials. In general by the 7-12 component, the main material is 4-6, such as quartz sand, limestone, feldspar, sodium carbonate, boric acid, lead compounds, barium compounds, according to the introduction of oxides in the glass structure effect, can be divided into glass forming oxide materials, intermediate oxide materials, network oxides materials, according to the the properties of oxide, can be divided into raw material, acid alkali metal oxide oxide materials. The glass batch is obtained some necessary properties and accelerate the melting process of raw materials, although less, but it is very important that these materials as clarifying agent, fluxing agent, coloring agent, bleaching agent, emulsifying agent, oxidizing agent and reducing agent etc..The same raw materials, different formulations, the same raw materials, different habitats and different indicators, will affect product quality and production costs. In the case of a small gap in raw material costs, the glass bottles produced are very different from each other in the comparison of small samples, and the difference can only be seen in batch production.

- Q: How is glass made? What material is it made of?.

- Bulletproof glass is the most important indicator of bullet proof ability. The target of bullet proof ability is measured from two aspects. On the one hand, it is the ability of security protection; on the other hand, it is the kill ability of the protective guns.

- Q: Will toughened glass break naturally?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- In the sun or under the light, look at the projection, float shadow is very weak, light transmission of good, lattice black lines, one by one

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1992 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Africa; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Extra Clear Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords