EPDM Waterproof Roofing Membrane for Environmental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Roofing Membrane for Environmental

Description Of EPDM Waterproof Roofing Membrane for Environmental:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Roofing Membrane for Environmental:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications of EPDM Waterproof Roofing Membrane for Environmental:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Roofing Membrane for Environmental:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

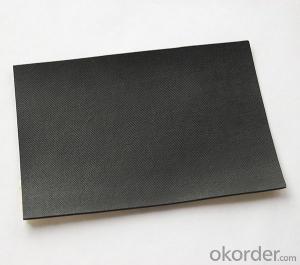

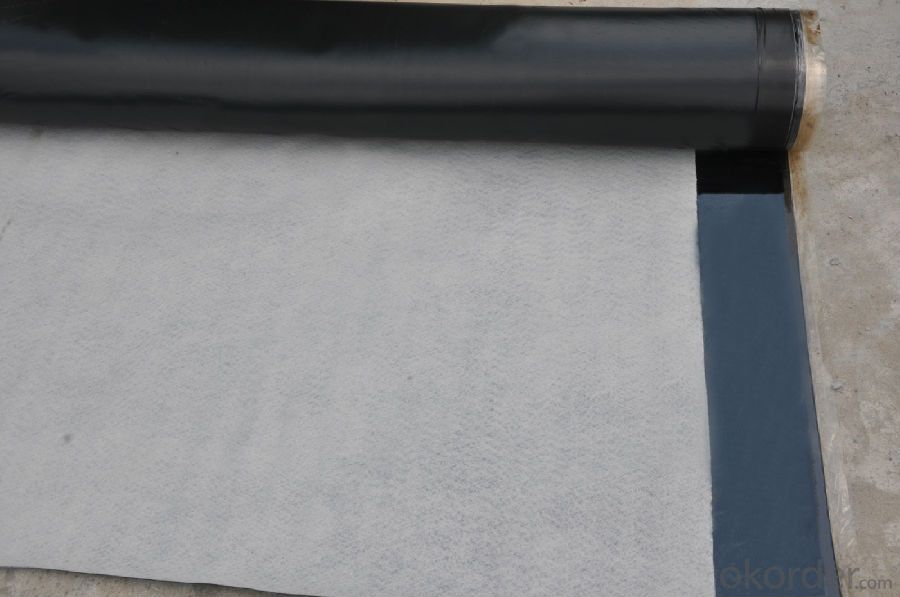

IMages of EPDM Waterproof Roofing Membrane for Environmental:

FAQ of EPDM Waterproof Roofing Membrane for Environmental:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be applied on curved surfaces?

- Yes, a waterproofing membrane can be applied on curved surfaces. In fact, waterproofing membranes are designed to be flexible and adaptable, making them suitable for application on various shapes and contours, including curved surfaces. These membranes are typically made from materials such as modified bitumen, polyurethane, or rubber, which have excellent elongation and flexibility properties. They can be easily molded and stretched to conform to curved surfaces without compromising their waterproofing capabilities. This allows for effective waterproofing of structures with curved components like roofs, balconies, tunnels, and tanks. Proper installation techniques and specialized tools may be required to ensure proper adherence and complete coverage on curved surfaces, but with the right expertise and materials, waterproofing membranes can be successfully applied on curved surfaces.

- Q: Can a waterproofing membrane be used on precast chrome surfaces?

- Yes, a waterproofing membrane can be used on precast chrome surfaces. The membrane will provide a protective barrier against water penetration, ensuring the durability and longevity of the precast chrome surfaces.

- Q: Can a waterproofing membrane be used on metal surfaces?

- Yes, a waterproofing membrane can be used on metal surfaces. Waterproofing membranes are designed to protect surfaces from water penetration and can be applied to a variety of materials, including metal. These membranes are typically made of materials such as modified bitumen, EPDM, PVC, or TPO, which provide a durable and watertight barrier. Applying a waterproofing membrane to a metal surface can help prevent corrosion, rust, and water damage, making it a suitable solution for protecting metal structures, roofs, or surfaces that are exposed to moisture or water. However, it is important to ensure that the specific waterproofing membrane being used is compatible with the type of metal surface and that proper installation guidelines are followed for optimal performance and longevity.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Certainly! Waterproofing membranes can be applied to tunnels that have emergency exits. It is strongly advised to utilize a waterproofing membrane in these tunnels to prevent water infiltration and safeguard the integrity of the exits. These membranes are specifically designed to establish a barrier against water and moisture, guaranteeing that the tunnels stay dry and unharmed by water. This is particularly crucial for emergency exits, as they must remain accessible and operational under all circumstances. By installing a waterproofing membrane, the tunnels can be adequately shielded from potential water ingress, thus ensuring the safety and functionality of the emergency exits.

- Q: Can a waterproofing membrane be used on precast copper surfaces?

- Precast copper surfaces can indeed utilize a waterproofing membrane. These membranes possess adaptability and can be utilized across a diverse range of surfaces, including copper. Their primary purpose is to establish a protective barrier that hinders water infiltration and safeguards the underlying structure from moisture-induced harm. With accurate application, a waterproofing membrane can proficiently seal precast copper surfaces, securing enduring defense against water intrusion. Nevertheless, it is vital to verify the compatibility of the membrane with copper and conduct thorough surface preparation to guarantee optimal adhesion and performance.

- Q: Can waterproofing membranes be used on concrete dams?

- Yes, waterproofing membranes can be used on concrete dams. These membranes are designed to provide a protective barrier against water penetration, helping to prevent leaks and ensure the structural integrity of the dam. By applying the waterproofing membrane to the concrete surface, it can effectively seal the pores and cracks, making the dam more resistant to water damage.

- Q: How does a waterproofing membrane handle joint movement?

- To prevent water infiltration and maintain its effectiveness, a waterproofing membrane is specially crafted to handle joint movement. It accomplishes this by exhibiting flexibility and the ability to adapt to the expansion and contraction of joints. When joints experience movement due to factors like temperature fluctuations or settling of the structure, a waterproofing membrane must have the capability to stretch and compress without tearing or compromising its waterproofing properties. This is typically achieved through the utilization of elastomeric materials, such as rubber or synthetic polymers, which boast exceptional elongation and recovery properties. Moreover, waterproofing membranes may incorporate reinforcing materials, such as fabric or mesh, to enhance their tensile strength and their capacity to withstand joint movement. These reinforcements assist in distributing the stresses caused by joint movement, thus preventing localized damage and preserving the integrity of the membrane. Furthermore, certain waterproofing membranes possess special adhesive properties that enable them to tightly bond to the surfaces they are applied to, including the edges of joints. This adhesive bond plays a crucial role in establishing a continuous barrier against water penetration, even in the presence of joint movement. In summary, a waterproofing membrane is designed to exhibit flexibility and durability, ensuring effective management of joint movement, long-term protection against water intrusion, and the preservation of the structural integrity of the building or structure.

- Q: Can a waterproofing membrane be used on nickel surfaces?

- Indeed, nickel surfaces can benefit from the use of a waterproofing membrane. These membranes are frequently employed in construction and building ventures to safeguard surfaces against water damage and moisture infiltration. They serve as a barrier, preventing water from seeping through the surface and causing harm. Like any other metal surfaces, nickel surfaces can be vulnerable to corrosion and water-induced damage. By applying a waterproofing membrane, the nickel surface can be effectively shielded from water and moisture, thereby prolonging its lifespan and preserving its integrity. However, it is crucial to guarantee that the chosen waterproofing membrane is suitable for use on nickel surfaces. Different membranes may have distinct compatibility requirements, which is why it is advisable to consult the manufacturer or a professional for guidance on proper application and compatibility.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They can effectively prevent water intrusion and protect homes from moisture damage, making them an ideal solution for basements, foundations, roofs, and other areas prone to water leakage.

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, bridge decks and roadways can benefit from the use of a waterproofing membrane. This protective layer prevents water infiltration and increases the lifespan of the structure. Given the harsh weather conditions and heavy traffic that bridge decks and roadways face, a waterproofing membrane is essential. Water penetration can cause damage to bridge decks and roadways, including corrosion of steel reinforcements and deterioration of concrete. By applying a waterproofing membrane, a barrier is created to prevent water from seeping into the structural elements. This reduces the risk of corrosion and extends the durability of the bridge or roadway. Additionally, a waterproofing membrane can help prevent the formation of cracks and potholes, which are often caused by the freeze-thaw cycle and water penetration. By keeping the surface of the bridge deck or roadway dry, the membrane maintains its structural integrity and avoids costly repairs or premature replacement. It is important to consider factors such as material selection, installation techniques, and maintenance when using a waterproofing membrane in bridge decks or roadways. The chosen membrane should be compatible with the construction materials, and the installation process must be done correctly to ensure a watertight seal. Regular maintenance and inspections should also be done to identify any issues or damage to the membrane. This allows for timely repairs and ensures its effectiveness over time. Overall, using a waterproofing membrane in bridge decks or roadways is an efficient solution to protect against water damage and extend the lifespan of these critical infrastructure elements.

Send your message to us

EPDM Waterproof Roofing Membrane for Environmental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords