Steel Plate of Color Coated Gi Corrugation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Details

Basic Info.

Type:Steel Plate

Standard:ASTM, GB, JIS

Certification:ISO, SGS

Surface Treatment:Coated

Technique:Cold Rolled

Application:Ship Plate

Special Use:High-strength Steel Plate

Stock:Stock

MOQ:25 Tons

Material:SGCC,Sgch.Full Hard/Soft

Spangle:Regular/Big/Small/Zero

Zn Coated:60-120G/M2

Width:760-1250 Mm

Length:Under 5 Meter

Bundle Weight:2-3 Tons

Export Markets:South America, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Standard Export Package

Standard:SGS, ISO9001

Origin:Boxing County, Shandong Province

HS Code:72107010

Production Capacity:60000 Tons/Year

Product Description

corrugation of hdgi for roofing :

| With the professional produce line, we can manufacture the best quality with competitive price as below: | |

| Thickness: | 0.18-0.80 mm |

| Sheet Width: | 760-1075 mm |

| Bundle weight: | 2.0-3.0 MT |

| Surface finish : | 60-120g/m2 zinc coating and the customers requirment! |

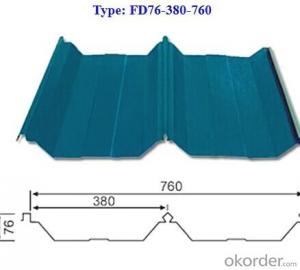

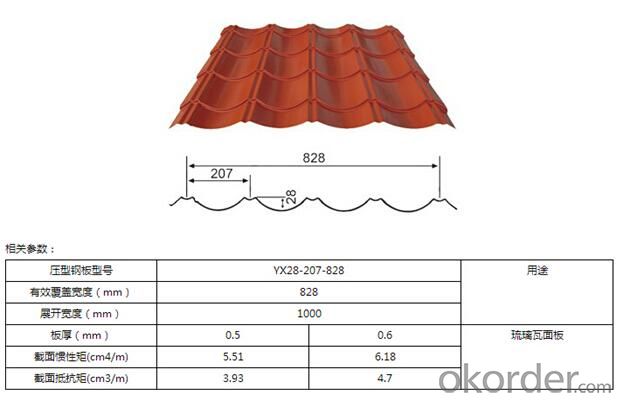

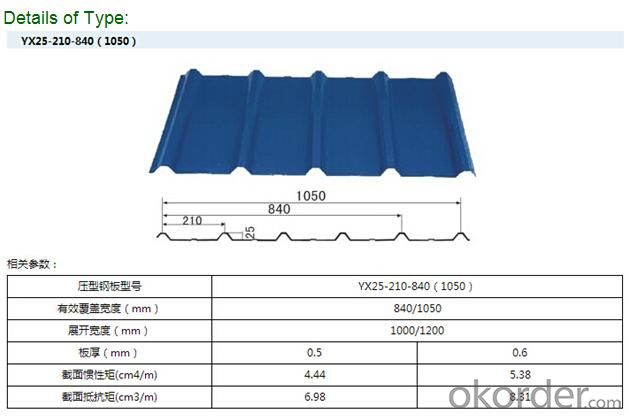

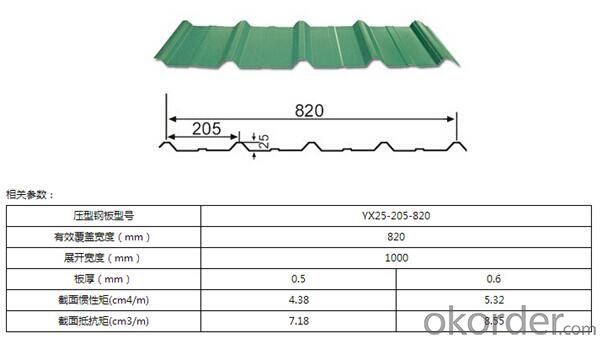

| Type: | YX28-207-828, YX14-63.5-850, YX15-225-900, YX35-125-750 , YX76-380-760, YX12-110-880, YX10-130-910, YX25-205-820/1025, YX25-210-840/1050, YX20-215-860/1075. |

| Standard: | JIS G3302, JIS G3313, ASTM A653, GB/T2518-88, GB11253-89,ASTM A1008- 2000,BS,ETC. |

| Packing: | wrapped by plastic film and waterproof paper, and then fastened on wooden pallet. Used in building material field,Pipe making, furniture making,others |

| MOQ: | 25 tons |

| Delivery times : | 20 days after received T/T or L/C |

| Payment terms : | T/T or L/C ( or as your demand) |

| Supply ability : | 6,000 ton per month |

| County we ever exported: Indonesia, Georgia, Mozambique, Somalia, Myanmar, Argentina,India,Dubai, and Turkmenistan. we can supply you the products you need with most competitive price and high quality. special size and standard can be accepted! | |

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q:How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they are a crucial raw material for manufacturing various components such as frames, beams, plates, and structural parts. These coils are processed through cutting, bending, and welding techniques to form the required shapes and structures used in the construction industry.

- Q:I made a wood crossbow body but all I need is a bow which I want to be metal. I've used a thin steel sheet that I cut to appropriate size but when it bent with the string strung, it never went to original shape after being shot. I used a slightly thicker and it wouldn't bend at all. Anybody know what thickness and type to use? Any real answers are very appreciated. Thanks.

- You are trying to use plain carbon steel which only can be bent a little bit if it is to return to its original shape. You have to use spring steel or high carbon steel that is intended to be bent a lot and still recover to its original shape. Most people making crossbows with metal bows get a piece of steel from a leaf spring of a vehicle and grind it to shape. A steel bow cross bow almost always needs a very strong trigger mechanism and a miniature wench to pull the steel bow string into position. You might be better off making the bow of wood.

- Q:Are steel buildings or homes better then wooden buildings? Why?

- Steel is better than wood. Steel can support more weight than wood. Steel is also much more durable than wood. Termites and rot are not a problem, which results in lower maintenance cost later. Also, wood can rot and warp whereas steel will not. Steel is also more economical than wood. The construction requires less labor, and as a result the labor cost is much lower. Steel is fire resistant, which will lower insurance costs.

- Q:Is steel cut really better? The nutritional profiles are nealy identical. Which one has the best flavor??Thanks!

- Miss Anthrope There is some added nutritional advantage to using steel cut oats , but that is because they are less processed . However they will take longer to cook If you are planning to make oatmeal for breakfast or something . Place the steel cut oats in your crock pot the night before and when you wake up you have oat meal. Rolled oats are equally good for you . I use them in many recipes . I use them to make crusts for many desert bars . Or just plain oatmeal or in pancakes . Just stay away from quick oats and instant oats . All the nutrition is processed out of them . You are essentially eating empty calories with no value.

- Q:What are the main applications of steel coils?

- The main applications of steel coils include manufacturing of automobiles, construction materials, appliances, machinery, and various industrial sectors. They are also used in the production of pipes, tubes, roofing, and packaging materials.

- Q:What are the different types of steel coil surface treatment options?

- There are several different types of steel coil surface treatment options available, each serving a specific purpose and providing various benefits. Some of the common surface treatment options include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, which forms a protective zinc coating on the surface. Galvanizing provides excellent corrosion resistance and helps in extending the lifespan of the steel coil. 2. Electro-galvanizing: Similar to hot-dip galvanizing, but instead of immersing the coil in molten zinc, an electric current is used to deposit a thin layer of zinc onto the steel surface. Electro-galvanizing provides a smoother and thinner zinc coating, making it suitable for applications that require a more aesthetic finish. 3. Pre-painted or coated: Steel coils can be coated with a layer of paint or other protective coatings before they are formed into various products. This type of treatment provides additional protection against corrosion and enhances the aesthetic appearance of the steel coil. 4. Organic coating: Organic coatings are typically applied to steel coils to provide protection against corrosion and improve the overall durability of the product. These coatings can be in the form of epoxy, polyurethane, or other types of polymer-based materials. 5. Pickling: Pickling is a surface treatment process that involves removing impurities and scale from the steel coil by immersing it in an acid solution. This treatment helps in improving the adhesion of subsequent coatings and prepares the surface for further processing or finishing. 6. Oil coating: Steel coils can be coated with a thin layer of oil to protect the surface from oxidation and rust during storage or transportation. This coating is typically used as a temporary measure and is usually removed before further processing. 7. Shot blasting: Shot blasting involves propelling small metal particles at high velocity onto the steel coil surface. This process helps in removing rust, scale, and other contaminants, providing a clean and roughened surface for better adhesion of subsequent coatings. These are some of the commonly used steel coil surface treatment options. The choice of treatment depends on the specific requirements of the application, such as corrosion resistance, aesthetic appearance, or improved adhesion.

- Q:How are steel coils cleaned?

- Steel coils are typically cleaned using a combination of chemical and mechanical processes. The coils are first treated with a degreasing agent to remove any oil or grease present on the surface. Then, high-pressure water jets or brushes are used to scrub away any remaining dirt or contaminants. The coils may also undergo a rinsing process to ensure all cleaning agents are removed. Additionally, some manufacturers may use acid cleaning or pickling techniques to remove scale or rust from the surface of the coils.

- Q:In construction, what types of stress require steel to be placed in footings?

- Bending moment , shear stress and punching stresses

- Q:Is the product of mild steel environmentally friendly? does it produce any emissions?The same question for leather aswell.

- Steel just rusts, it doesn't produce any emissions just sitting there. They even make architectural steel called Corten to rust to a nice patina. If you consider how the steel was made in the first place, a great big NO! Steel making requires massive amounts of electricity plus it gives off some nasty fumes in the liquid state. Leather itself doesn't emit much of anything, but the dyes might. Again though, if you look at how it's made, tanning leather is right up there with steel mills and paper mills for pollution, some of the worst.

- Q:What are the common applications of galvanized steel coils?

- Galvanized steel coils are commonly used in a variety of applications, including construction, automotive manufacturing, electrical appliances, and agricultural equipment. They are particularly useful for roofing and siding materials, as well as for creating durable and corrosion-resistant components in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Plate of Color Coated Gi Corrugation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords