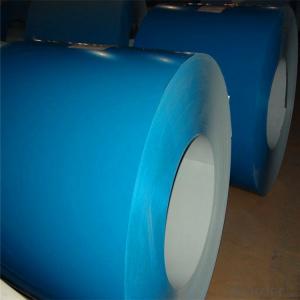

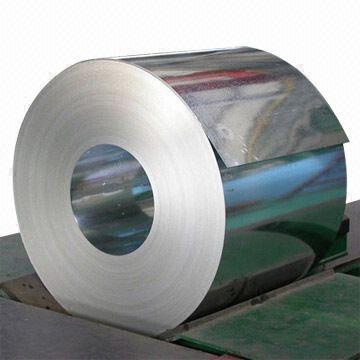

Hot dip galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION:

Standard | JIS G 3302, ASTM A653, EN10327,10143,GB/T 2518 |

Grade | SPCC, DX51D+Z,CS Type A.B.C |

Zinc Coating | galvanized(GI) |

Zinc Weight | 40~140/m2 |

Thickness | 0.18mm~1.2mm |

Width | 762mm-1,250mm |

Coil weight | 3-20 tons |

Surface processing | Zero Spangle |

Coil Chemical Processing | Skin Pass,chromate,dry,oiled |

packing | waterproof paper and galvanized steel protection cover and steel strip packed Or as you request. |

Application | Construction, hardware, home appliances, interior decoration... |

Advantages | 1. Good experience producing and trading on PPGI/galvanized steel coil /steel sheet. With quality assurance and certification . 2.With technology strength and powerful. 3. Shortest delivery time . 4. authentication service and Sincere Caring Services. 5. We strive to be NO.1 of the same trade |

If you have any need of GI or PPGI Coil,please feel free to contact me.

- Q: How are steel coils used in the manufacturing of building materials?

- Steel coils are used in the manufacturing of building materials as they provide a strong and durable base for various products. These coils are typically unrolled and shaped into different forms, such as sheets or beams, which are then used to create structures like roofing, siding, and framing. The flexibility and strength of steel make it an ideal material for construction purposes, ensuring buildings are sturdy and long-lasting.

- Q: What are the common methods of forming steel coils?

- The common methods of forming steel coils include hot rolling, cold rolling, and strip casting.

- Q: How are steel coils used in the production of infrastructure materials?

- The durability, versatility, and strength of steel coils make them widely used in the production of infrastructure materials. Typically, these coils are made from hot-rolled steel, forming large rolls or coils that are easily transported and handled. One common application of steel coils in infrastructure materials involves producing steel sheets and plates. These coils can be further processed to create flat sheets of steel, which are then utilized in various construction purposes. For instance, steel sheets are frequently employed in manufacturing bridges, highways, and buildings due to their ability to withstand heavy loads and adverse weather conditions. Another important use of steel coils in infrastructure materials is manufacturing pipes and tubes. Steel coils are often processed into seamless or welded pipes that find usage in water and gas pipelines, as well as the transportation of liquids and gases. Infrastructure projects prefer steel pipes and tubes due to their high strength, corrosion resistance, and ability to endure high-pressure environments. Moreover, steel coils are also employed in the production of reinforcing bars or rebars, crucial components in the construction of reinforced concrete structures. These rebars, made from coiled steel, are embedded within concrete to provide tensile strength and enhance the structural integrity of buildings, bridges, and other infrastructure projects. Steel coils enable efficient production of rebars, ensuring consistent quality and size for reinforced concrete constructions. In conclusion, the use of steel coils is essential in the production of infrastructure materials. Their contribution to manufacturing steel sheets, pipes, and rebars ensures the durability, strength, and reliability of infrastructure projects. By providing a versatile and robust material, steel coils contribute to the development of safe and long-lasting structures in our built environment.

- Q: How are steel coils made?

- Steel coils are made through a process called hot rolling, where a large slab of steel is heated and passed through a series of rolling mills to gradually reduce its thickness and shape it into a coil.

- Q: What are the different types of steel coil coating materials?

- There exist various steel coil coating materials utilized in diverse industries and applications. Some frequently encountered types encompass: 1. Polyester: Renowned for their resilience and ability to withstand weathering, polyester coil coating materials find frequent application in outdoor settings like roofing and cladding. They offer exceptional protection against fading, chalking, and corrosion. 2. Polyvinylidene Fluoride (PVDF): PVDF coil coating materials exhibit remarkable resistance to chemicals, UV radiation, and weathering. They are commonly employed in architectural contexts, providing prolonged color retention and excellent defense against harsh environmental conditions. 3. Polyurethane: Possessing a high degree of flexibility and adhesion, polyurethane coil coating materials prove ideal for scenarios necessitating resistance to abrasion, impact, and bending. The automotive and appliance industries commonly rely on them. 4. Epoxy: Epoxy coil coating materials are celebrated for their remarkable adhesion and corrosion resistance. Industries such as metal furniture, storage tanks, and machinery frequently utilize them to ensure long-lasting protection against chemicals and abrasion. 5. Silicone Modified Polyester (SMP): SMP coil coating materials combine the robustness of polyester with the flexibility of silicone. They are prevalent in agricultural and industrial settings, offering outstanding resistance to chipping, cracking, and peeling. These merely serve as a few instances of the diverse array of steel coil coating materials currently available in the market. The selection of a coating material hinges upon the specific requirements of an application, including durability, weather resistance, chemical resistance, and aesthetics.

- Q: What types of steel are used in steel coils?

- There are various types of steel used in steel coils, including carbon steel, stainless steel, galvanized steel, and high-strength low-alloy steel.

- Q: They say it's some six times stronger than steel. need some explanation.

- Lol I dont know where you heard that, there probably saying for small insects like for instence a small instect in a spider web is like us( humans ) in steel but no I could break through a web with my soft hair or finger, like not an ant because there extremely strong but like a flea

- Q: How are steel coils inspected for straightness?

- To ensure compliance with quality standards, steel coils undergo a variety of methods to inspect their straightness. Among these, visual inspection is commonly employed, wherein trained inspectors meticulously examine the coil's edges, surface, and overall shape for any visible flaws or irregularities that might indicate a lack of straightness. An alternative approach involves measuring the coil's straightness using precise instruments. This entails taking measurements at different points along the coil's length and comparing them to specified tolerances. Accurate assessment of the deviation from the desired straightness is achieved using techniques like laser measurements or straightness gauges. Moreover, certain coils undergo non-destructive testing, such as magnetic particle inspection or ultrasonic testing, to uncover any internal defects or stresses that may impact their straightness. These tests are capable of identifying hidden flaws that visual inspection alone may fail to detect. Additionally, some manufacturers employ automated inspection systems that leverage advanced technologies like computer vision or artificial intelligence. These systems swiftly scan the coil's surface and analyze it for any deviations from straightness, generating precise measurements and ensuring consistent quality. In summary, the inspection of steel coils to verify their straightness involves a combination of visual inspection, precise measurements, non-destructive testing, and advanced technologies. These methods work together to identify any deviations from the specified straightness, ensuring that only coils meeting the required standards are utilized in various applications.

- Q: What are the common coil defects and their causes?

- Common coil defects can include misshapen coils, coil breaks, and coil slippage. Misshapen coils can be caused by improper winding tension or uneven material thickness. Coil breaks may occur due to excessive tension during winding, inadequate material strength, or improper handling. Coil slippage can result from insufficient binding or improper tension control. These defects can affect the performance and integrity of the coil, leading to potential issues in its functionality.

- Q: How are steel coils used in the production of agricultural fencing?

- Steel coils are used in the production of agricultural fencing as they serve as the primary material for creating strong and durable fence wires. These coils are processed and cut into specific lengths, then woven or welded together to form the fencing panels. The high tensile strength of steel ensures that the fencing can withstand the pressure from animals, weather conditions, and other external factors, making it an ideal choice for securing agricultural areas.

Send your message to us

Hot dip galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords