parallel flange channel steel in U shaped

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Products Information:

| 1.Products size | Size : 5#--40# | ||||

| 2.Products length | Lengths : 6m--12m | ||||

| 3.Product standard | Standard : GB, ASTM, JIS, DIN | ||||

| 4.Product Grade | Grades : Q235B, Q345B, SS400 | ||||

| 5.Application | Used or building structures, vehicle | ||||

| manufacturing and other industrial structures | |||||

| 6.Customized requirement | Can produce special specification products | ||||

| as per our customers' requirement | |||||

| 7.Delivery Time | 15-30 days after recieve the LC or pre-paid | ||||

| 8.Detail Package | Bundles, seaworthy wooden cases with or without | ||||

| edge protector, steel hoop and seals, or as per | |||||

| customers' requirements | |||||

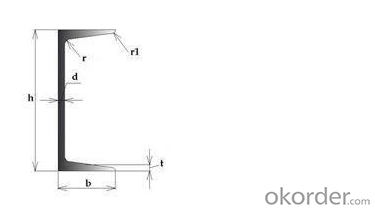

Drawings and Datas (for know more about the structure and size)

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

- Q:Can stainless steel angles be used in chemical storage tanks?

- Yes, stainless steel angles can be used in chemical storage tanks. Stainless steel is known for its excellent corrosion resistance and durability, making it an ideal material for storing chemicals. The use of stainless steel angles in the construction of the tank provides structural support and stability. Additionally, stainless steel is non-reactive to most chemicals, ensuring that the stored substances will not be contaminated. It is important, however, to select the appropriate grade of stainless steel that is compatible with the specific chemicals being stored in order to ensure optimal performance and longevity of the tank.

- Q:Are stainless steel angles suitable for outdoor railing systems?

- Yes, stainless steel angles are suitable for outdoor railing systems. Stainless steel is highly resistant to corrosion, making it a durable and long-lasting material for outdoor applications. It can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or rusting. Additionally, stainless steel angles provide structural strength and stability, ensuring the safety and security of the railing system.

- Q:Are stainless steel angles suitable for HVAC systems?

- Yes, stainless steel angles are suitable for HVAC systems. Stainless steel is highly resistant to corrosion, making it ideal for use in HVAC systems where exposure to moisture and other environmental factors is common. Additionally, stainless steel angles provide structural support and are known for their durability, ensuring a long-lasting and reliable solution for HVAC installations.

- Q:What is the weight calculation formula for stainless steel angles?

- The weight calculation formula for stainless steel angles is: weight = (side A + side B - thickness) x thickness x 0.00793.

- Q:Can stainless steel angles be welded?

- Yes, stainless steel angles can be welded. Stainless steel is a commonly used material in the welding industry due to its high corrosion resistance, strength, and durability. Welding stainless steel angles requires the use of specialized welding techniques and equipment, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. These methods allow for a strong and clean weld joint, ensuring the integrity and longevity of the stainless steel angles. However, it is important to note that proper preparation and cleaning of the stainless steel surfaces, as well as the use of appropriate filler materials, are crucial for achieving a successful weld.

- Q:How are stainless steel angles measured?

- When measuring stainless steel angles, two main dimensions are commonly used: the length of each leg and the thickness of the material. The length of each leg represents the distance from the intersection point to the end of the leg, while the thickness refers to the measurement from one edge to the other. These dimensions are typically expressed in inches or millimeters. Moreover, the angle itself is often identified by its nominal size, which is determined by the length of the legs. For instance, a stainless steel angle with equal leg lengths of 2 inches would be called a 2-inch angle. In conclusion, measuring stainless steel angles involves considering the leg length, material thickness, and nominal angle size.

- Q:Are stainless steel angles suitable for the production of street signs?

- Yes, stainless steel angles are suitable for the production of street signs. Stainless steel is a durable and corrosion-resistant material that can withstand harsh weather conditions and the wear and tear of outdoor environments. The use of stainless steel angles ensures that the street signs are strong and stable, with the ability to withstand impacts and remain in place for a long time. Additionally, stainless steel is easy to clean and maintain, which is important for keeping street signs visible and legible. Overall, stainless steel angles are a reliable choice for the production of street signs due to their durability, resistance to corrosion, and low maintenance requirements.

- Q:Can stainless steel angle be used in electrical or electronic applications?

- Indeed, electrical or electronic applications can make use of stainless steel angle. Renowned for its remarkable resistance to corrosion and its durability, stainless steel emerges as an appropriate material for diverse industries, including electrical and electronic applications. In the construction of electrical enclosures, junction boxes, and control panels, where shielding against moisture, chemical exposure, and physical harm becomes essential, stainless steel is extensively employed. Moreover, stainless steel angle frequently finds application in the production of brackets, supports, and frames for electronic equipment, ensuring robustness and stability.

- Q:What are the standard finishes available for stainless steel angles?

- The standard finishes available for stainless steel angles include mill finish, brushed finish, and polished finish.

- Q:What are the weight limits for stainless steel angles?

- The weight limits for stainless steel angles can vary depending on various factors such as the dimensions of the angle, the grade of stainless steel used, and the specific application it is being used for. In general, stainless steel angles are designed to support a certain amount of weight based on their structural integrity and load-bearing capacity. It is recommended to consult engineering specifications or contact the manufacturer for accurate weight limits specific to the stainless steel angle being used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

parallel flange channel steel in U shaped

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords