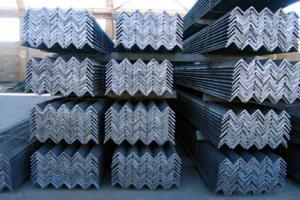

GALVANIZED STEEL ENGLE BAR EQUAL STEEL BAR UNEQUAL STEEL BAR JIS GB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Galvanized Angle Steel

Galvanized Angle Steel Zinc Thickness: 15--80μ

Hot Galvanized Angle Steel ss400

Sizes: 25*25~250*250mm

Grades: SS400,SS540,A36

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m

3. Sizes:

HOT DIPPED GALVANIZED EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M |

30 | 30 | 2.5---4.0 | 6M |

38 | 38 | 2.5 | 6M |

38 | 38 | 3.0---5.0 | 6M |

40 | 40 | 3.0---6.0 | 6M |

50 | 50 | 3 | 6M |

50 | 50 | 3.7---6.0 | 6M |

60 | 60 | 5.0---6.0 | 6M |

63 | 63 | 6.0---8.0 | 6M |

65 | 65 | 5.0---8.0 | 6M |

70 | 70 | 6.0---7.0 | 6M |

75 | 75 | 5.0---10.0 | 6M |

80 | 80 | 6.0---10.0 | 6M |

90 | 90 | 6.0---10.0 | 6M |

100 | 100 | 6.0---12.0 | 6M |

120 | 120 | 8.0-12.0 | 6M |

125 | 125 | 8.0---12.0 | 6M |

130 | 130 | 9.0-12.0 | 6M |

140 | 140 | 10.0-16.0 | 6M |

150 | 150 | 10---15 | 6M |

160 | 160 | 10---16 | 6M |

180 | 180 | 12---18 | 6M |

200 | 200 | 14---20 | 6M |

5. PROCESS: HOT-DIP GALVANIZATION of Galvanized Angle Steel

Hot-dip galvanization is a form of galvanization. It is the process of coating iron, steel or aluminium with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 860 °F (460 °C). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements. Galvanized steel is widely used in applications where corrosion resistance is needed, and can be identified by the crystallization patterning on the surface (often called a "spangle").

Usage & Applications of Galvanized Angle Steel

Galvanized steel can be welded; however, one must exercise caution around the resulting zinc fumes. Galvanized steel is suitable for high-temperature applications of up to 392 °F (200 °C). The use of galvanized steel at temperatures above this will result in peeling of the zinc at the inter metallic layer. Electrogalvanized sheet steel is often used in automotive manufacturing to enhance the corrosion performance of exterior body panels; this is, however, a completely different process which tends to achieve lower coating thicknesses of zinc.

Like all other corrosion protection systems, galvanizing protects steel by acting as a barrier between steel and the atmosphere. However, zinc is a more electronegative metal in comparison to steel, this is a unique characteristic for galvanizing which means that when a galvanized coating is damaged and steel is exposed to the atmosphere, zinc can continue to protect steel (often within an annulus of 5 mm above which electron transfer rate decreases)..

Packaging & Delivery of Galvanized Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

- Q: Are stainless steel angles suitable for the production of street signs?

- Yes, stainless steel angles are suitable for the production of street signs. Stainless steel is highly durable, resistant to corrosion, and can withstand harsh weather conditions, making it an ideal material for outdoor applications like street signs. Additionally, stainless steel angles provide structural stability and can be easily fabricated to form the desired shape for street signs.

- Q: Can stainless steel angles be used in chemical storage tanks?

- Indeed, chemical storage tanks can make use of stainless steel angles. Stainless steel possesses outstanding corrosion resistance and durability, rendering it an ideal substance for chemical storage. By incorporating stainless steel angles into the tank's construction, structural support and stability are provided. Moreover, stainless steel exhibits non-reactivity towards the majority of chemicals, guaranteeing the preservation of stored substances without contamination. Nonetheless, it is crucial to carefully choose the appropriate grade of stainless steel that is compatible with the specific chemicals being stored, as this will guarantee optimal performance and longevity of the tank.

- Q: Can stainless steel angles be used in the construction of solar panel frames?

- Indeed, the utilization of stainless steel angles is feasible in the fabrication of solar panel frames. Renowned for its sturdiness and resistance to corrosion, stainless steel emerges as an appropriate substance for outdoor purposes, including solar panel frames. By offering structural reinforcement and steadiness, stainless steel angles guarantee that the solar panels can endure diverse atmospheric conditions and persist undamaged for extended durations. Furthermore, stainless steel possesses an impressive strength-to-weight ratio, rendering it a perfect selection for constructing frames that are lightweight yet sturdy enough to sustain the weight of the solar panels. In conclusion, stainless steel angles present themselves as a reliable and enduring alternative for the construction of solar panel frames.

- Q: What is the difference between hot-rolled and cold-rolled stainless steel angles?

- Hot-rolled and cold-rolled stainless steel angles are two different manufacturing processes used to produce stainless steel angles with distinct characteristics. Hot-rolled stainless steel angles are formed by heating a stainless steel billet or slab above its recrystallization temperature and then rolling it into the desired shape. This process results in a larger grain structure and a rougher surface finish. Hot-rolled angles often have rounded edges and are generally less precise in terms of dimensions and tolerances. However, they tend to be more cost-effective and are commonly used in structural applications where aesthetics are not a primary concern. On the other hand, cold-rolled stainless steel angles are formed by passing hot-rolled angles through a series of rollers at room temperature. This process results in a smoother surface finish and a more precise shape with sharper edges. Cold-rolled angles have a smaller grain structure, which enhances their strength and overall quality. These angles are often used in applications where appearance and dimensional accuracy are critical, such as architectural designs, decorative trim, or precision engineering. In summary, the main differences between hot-rolled and cold-rolled stainless steel angles lie in their manufacturing processes, surface finish, dimensional accuracy, and intended applications. Hot-rolled angles are more cost-effective, have a rougher surface finish, and are commonly used in structural applications. Cold-rolled angles, on the other hand, have a smoother surface finish, sharper edges, and are preferred for applications where appearance and precision are important.

- Q: How do you calculate the bending stress of a stainless steel angle?

- To calculate the bending stress of a stainless steel angle, you need to consider the moment of inertia, the distance from the neutral axis, and the applied bending moment. By using the formula for bending stress, which is stress = (M * y) / I, where M represents the bending moment, y is the distance from the neutral axis to the outermost fiber, and I is the moment of inertia, you can determine the bending stress on the stainless steel angle.

- Q: What are the tolerances for stainless steel angles?

- The tolerances for stainless steel angles typically depend on the specific industry or application requirements. However, common tolerances for stainless steel angles are usually specified in terms of dimensional accuracy, straightness, and surface finish. These tolerances ensure that the angles meet the desired specifications and can vary from a few thousandths of an inch to a few hundredths of an inch. It is important to consult the relevant standards or specifications for accurate information on tolerances for stainless steel angles.

- Q: What are the advantages of using stainless steel angles in marine applications?

- There are several advantages of using stainless steel angles in marine applications. Firstly, stainless steel is highly resistant to corrosion, making it ideal for use in marine environments where exposure to saltwater, humidity, and other harsh conditions is common. This corrosion resistance ensures that the angles will maintain their structural integrity and aesthetic appearance over time, reducing the need for frequent maintenance and replacement. Secondly, stainless steel angles offer excellent strength and durability. They can withstand heavy loads, impacts, and vibrations, making them suitable for various marine applications such as boat hulls, deck structures, and support systems. This strength and durability ensure the safety and reliability of the structures built with stainless steel angles. Additionally, stainless steel angles have a high melting point, making them resistant to fire and heat. This is crucial in marine applications as it provides an added level of safety by preventing the angles from warping or melting in extreme temperatures. Moreover, stainless steel angles have a sleek and modern appearance, which is desirable in many marine applications. They can be easily fabricated and customized to fit specific design requirements, enhancing the overall aesthetics of the marine structures. Furthermore, stainless steel is environmentally friendly. It is 100% recyclable, reducing waste and minimizing the impact on the environment. This sustainability aspect is highly valued in the marine industry, where there is a growing emphasis on eco-friendly practices. In conclusion, the advantages of using stainless steel angles in marine applications include corrosion resistance, strength and durability, resistance to fire and heat, aesthetic appeal, and environmental sustainability. These qualities make stainless steel angles a reliable and cost-effective choice for various marine structures.

- Q: How do stainless steel angles compare to other types of angles?

- Stainless steel angles are highly regarded for their superior strength, durability, and corrosion resistance, making them a preferred choice in various industries. When comparing stainless steel angles to other types of angles, such as aluminum or carbon steel angles, several key differences become apparent. One significant advantage of stainless steel angles is their exceptional resistance to corrosion. This property makes stainless steel angles ideal for applications that involve exposure to moisture, chemicals, or other corrosive elements. Unlike aluminum angles, which may corrode or develop oxidation over time, stainless steel angles maintain their integrity and appearance even in demanding environments. Furthermore, stainless steel angles exhibit remarkable strength and durability. Compared to aluminum angles, stainless steel angles have a higher tensile strength, allowing them to withstand heavier loads and more rigorous conditions. This strength also translates into excellent structural stability, making stainless steel angles a reliable choice for construction and engineering projects. In terms of aesthetics, stainless steel angles offer a sleek and modern appearance. They can be easily polished or brushed to achieve a desired finish, adding an attractive and professional touch to architectural designs or interior applications. Conversely, aluminum angles may have a less refined appearance and are often used in applications where weight reduction is a priority. Although stainless steel angles tend to be more expensive than aluminum angles, they provide a longer service life and reduced maintenance costs due to their corrosion-resistant properties. Additionally, stainless steel angles are recyclable, making them an environmentally friendly choice. In summary, stainless steel angles surpass other types of angles in terms of corrosion resistance, strength, durability, and aesthetic appeal. While aluminum angles may be lighter and more cost-effective, stainless steel angles offer unmatched performance and reliability, making them the preferred choice for a wide range of applications.

- Q: What is stainless steel angle?

- Stainless steel angle, crafted from stainless steel, represents a metal profile. Its distinguishing feature lies in its L-shaped configuration, consisting of two legs of equal length that stand perpendicular to each other. This angle is formed by skillfully bending a stainless steel sheet or plate at a particular degree, typically 90 degrees, although alternative angles can also be achieved. This particular structural shape imparts remarkable strength and endurance, rendering stainless steel angle suitable for a wide array of applications across diverse industries, such as construction, manufacturing, and engineering. Moreover, the inherent corrosion-resistant qualities of stainless steel further enhance its aptness for outdoor and high-moisture settings. Stainless steel angle is frequently employed for purposes of structural support, framework establishment, bracing, and also for decorative motives. It is obtainable in various dimensions, thicknesses, and surface finishes, ensuring that specific requirements can be met effectively.

- Q: Can stainless steel angles be used in sports equipment manufacturing?

- Stainless steel angles are indeed applicable in the manufacturing of sports equipment. With its desirable properties such as high strength, corrosion resistance, and durability, stainless steel has become a favored option in various industries, including sports equipment manufacturing. In constructing different sporting equipment like goal posts, basketball hoops, tennis rackets, golf club heads, and gym equipment, stainless steel angles serve as reliable structural support capable of enduring the demanding requirements of sports activities. Moreover, stainless steel's easy maintenance and cleaning are crucial factors for sports equipment frequently exposed to sweat, dirt, and moisture. In conclusion, the strength, corrosion resistance, and longevity of stainless steel angles make them an appropriate material choice for producing sports equipment.

Send your message to us

GALVANIZED STEEL ENGLE BAR EQUAL STEEL BAR UNEQUAL STEEL BAR JIS GB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords