Aluminium Checkered Plate for Auto Trailers Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminium Checkered Plate for Auto Trailers Supply

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Checkered Plate for Auto Trailers Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Checkered Plate for Auto Trailers Supply

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

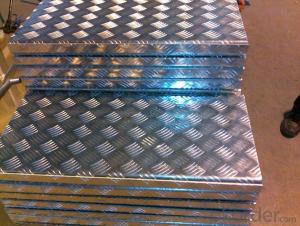

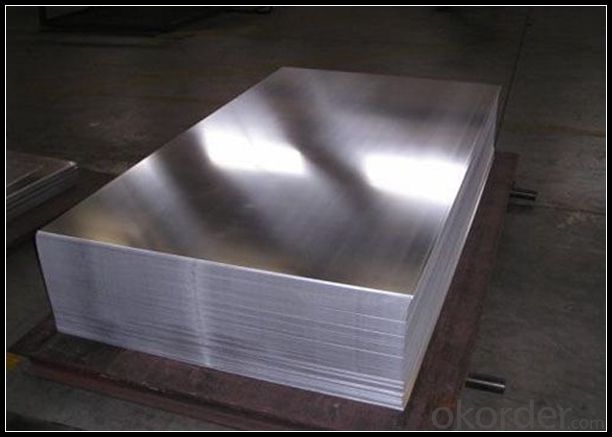

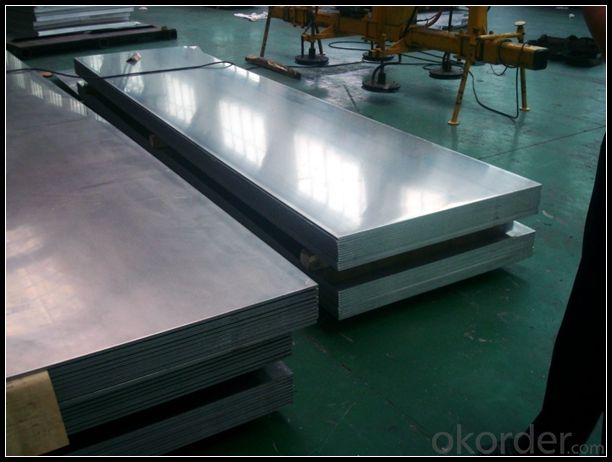

5. Image of Aluminium Checkered Plate for Auto Trailers Supply

6. Package and shipping of Aluminium Checkered Plate for Auto Trailers Supply

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What is the thermal conductivity of 101 aluminum sheets?

- The thermal conductivity of 101 aluminum sheets is influenced by several factors, including sheet thickness, aluminum purity, and measurement temperature. Typically, aluminum exhibits a significant thermal conductivity, varying from 205 to 250 watts per meter kelvin (W/mK). Nevertheless, it is recommended to consult specific technical data or liaise with a manufacturer for precise information regarding the thermal conductivity of 101 aluminum sheets.

- Q:How are aluminum sheets cleaned and maintained?

- Aluminum sheets can be cleaned and maintained by following a few simple steps. Firstly, they should be wiped down regularly with a soft cloth or sponge and mild detergent to remove any dirt or grime. Avoid using abrasive materials or cleaners that contain bleach or ammonia, as they can damage the surface. After cleaning, it is recommended to rinse the sheets thoroughly with clean water and dry them with a soft cloth to prevent water spots. To maintain their shine, applying a coat of aluminum polish or a mixture of vinegar and water can help remove any oxidation or dullness. Additionally, it is important to protect aluminum sheets from harsh elements by storing them in a dry and clean environment and avoiding contact with corrosive substances.

- Q:What are the different cutting tools used for aluminum sheets?

- There are several cutting tools that can be used for aluminum sheets, including power shears, hacksaws, circular saws with carbide-tipped blades, and plasma cutters. Each tool has its own advantages and is suitable for different applications depending on the thickness and size of the aluminum sheet.

- Q:What is the maximum temperature aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand depends on several factors, including the alloy composition and thickness of the sheet, as well as the specific application and environment in which it is being used. Generally, pure aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), but it begins to lose strength and stiffness at much lower temperatures. Most commercial aluminum alloys have higher melting points and can withstand higher temperatures. For example, 6061 aluminum alloy has a melting point of around 580 degrees Celsius (1076 degrees Fahrenheit), while 7075 aluminum alloy has a slightly higher melting point of around 640 degrees Celsius (1184 degrees Fahrenheit). However, it is important to note that the maximum temperature a sheet of aluminum can withstand without significant deformation or structural damage may be lower than its melting point. This is because aluminum's strength and mechanical properties degrade at elevated temperatures. In applications where aluminum sheets are subjected to high temperatures, it is crucial to consider the specific alloy and its thermal properties, as well as any potential changes in strength, hardness, or other relevant characteristics that may occur at elevated temperatures. Consulting material specifications, engineering guidelines, or seeking professional advice from metallurgical experts can provide more accurate and specific information regarding the maximum temperature capabilities of aluminum sheets for a particular application.

- Q:Hey.How come iron rust and aluminium does not?DETAILED ANSWER PLEASE.I want to understand this...THANKS.

- Aluminum DOES rust..... It oxidizes just like iron does..... Leave a piece of aluminum outside for a few months.... It will get a nice white powder on it which of course is aluminum oxide

- Q:What is the melting point of 101 aluminum sheets?

- Approximately 660 degrees Celsius or 1220 degrees Fahrenheit is the melting point of 101 aluminum sheets.

- Q:Can aluminum sheets be used for insulation?

- Yes, aluminum sheets can be used for insulation. Aluminum is a good conductor of heat and electricity, so it can effectively reflect and block thermal energy. Aluminum foil, for example, is commonly used as a radiant barrier in insulation systems. It helps to prevent heat transfer by reflecting radiant heat away from the building, thus reducing the amount of heat that enters or escapes through the insulated areas. Additionally, aluminum sheets can also be used as a vapor barrier to prevent moisture from penetrating into the insulation, which helps to maintain its effectiveness. Overall, aluminum sheets can be a cost-effective and efficient option for insulation purposes.

- Q:Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

- Q:What are the different methods for engraving aluminum sheets?

- There are several different methods for engraving aluminum sheets, each with its own advantages and applications. 1. Laser engraving: This is one of the most popular methods for engraving aluminum sheets. It uses a laser beam to vaporize the aluminum surface, creating a permanent and precise engraving. Laser engraving offers high precision, speed, and versatility, making it suitable for a wide range of applications. 2. Mechanical engraving: This method involves using a mechanical tool, such as a rotary cutter or diamond-tipped tool, to physically remove material from the aluminum surface. Mechanical engraving can achieve deep and detailed engravings, making it suitable for applications where durability and depth are important. 3. Chemical etching: Chemical etching involves using chemicals to selectively remove material from the aluminum surface. It is a highly precise method that can create intricate and detailed designs. Chemical etching is often used in industries such as electronics and aerospace, where precision and high-quality finishes are required. 4. CNC milling: Computer Numerical Control (CNC) milling is a method that uses a computer-controlled machine to remove material from the aluminum sheet. It can achieve precise and complex engravings, making it suitable for applications that require intricate designs or 3D engravings. 5. Hand engraving: Hand engraving involves using handheld tools, such as gravers or chisels, to manually create engravings on the aluminum surface. While it may not offer the same level of precision as other methods, hand engraving allows for artistic freedom and customization. Each method has its own advantages and limitations, so the choice of engraving method depends on factors such as the desired design, level of detail, production volume, and budget.

- Q:Are aluminum sheets suitable for chemical reactors?

- Yes, aluminum sheets can be suitable for chemical reactors depending on the specific application and conditions. Aluminum is known for its excellent corrosion resistance, especially when exposed to air or water, due to the formation of a protective oxide layer. This makes it suitable for many chemical reactions that involve non-aggressive substances. However, it is important to note that aluminum may not be suitable for reactors that handle highly acidic or alkaline solutions, as these can corrode the oxide layer and lead to degradation of the metal. Additionally, aluminum may react with certain chemicals, such as strong oxidizers, halogens, or strong bases, which could compromise the integrity of the reactor. In cases where aluminum is used in chemical reactors, it is common to employ protective coatings or linings to enhance its resistance to corrosion and chemical reactions. These coatings can provide an additional barrier between the aluminum and the reactants, ensuring a safe and effective operation. Ultimately, the suitability of aluminum sheets for chemical reactors depends on the specific chemical reactions, operating conditions, and the necessary level of corrosion resistance. It is always advisable to consult with experts and consider the compatibility of materials before selecting aluminum for such applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Checkered Plate for Auto Trailers Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords