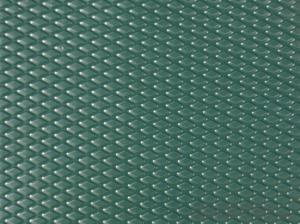

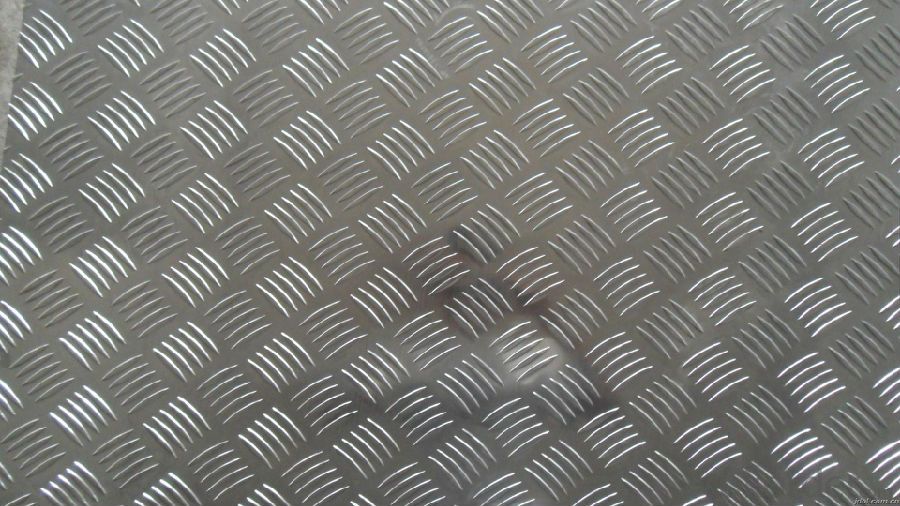

Hot/Cold Rolled Stucco Embossed Aluminium Checker Plate 5 bars /3 Bars /1 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Diamond Embossed Aluminium Plate/Sheet Alloy 5082 H12

Description

Aluminium sheet | |||||

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 18MT | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 15-30 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

According to the composition of alloy, it can be divided into 5 items.

1) High purity aluminum plate (rolling by the content above 99.9 high purity aluminum)

2) Pure aluminum plate (rolled by pure aluminum)

3) Alloy aluminum plate (composition of aluminum and other alloy material, usually alu-copper, alu-manganese, alu-silicon, alu-magnesium, and so on)

4) Composite aluminum plate or brazing plate (made by a variety of composite materials)

5) Alclad aluminum (coated aluminium sheet outside of aluminium sheet used for special purposes)

According to the thickness, it can be divided into 4 items.

1) Thin plate (aluminum sheet) 0.15-2.0mm

2) The conventional plate (aluminum sheet) 2.0-6.0mm

3) Medium plate (aluminum plate) 6.0-25.0mm

4) Thick plate (aluminum plate) 25-200mm

5) More than 200 super- thick plate

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q:Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q:Can aluminum sheet be used in marine environments?

- Yes, aluminum sheet can be used in marine environments. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which helps to prevent further corrosion even in saltwater environments. Additionally, aluminum is lightweight, which makes it an ideal choice for marine applications where weight reduction is crucial. Aluminum sheet is commonly used in boat hulls, decks, and other marine structures due to its durability, strength, and resistance to corrosion.

- Q:Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q:What is the price range of 101 aluminum sheets?

- The price range of 101 aluminum sheets can vary depending on factors such as size, quantity, and supplier. However, generally speaking, the price range for 101 aluminum sheets can be anywhere from $50 to $150 per sheet.

- Q:What are the different methods of surface finishing for aluminum sheets?

- There are several methods of surface finishing for aluminum sheets, each with its own advantages and applications. Some of the common methods include: 1. Anodizing: This process involves immersing the aluminum sheet in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. Anodizing provides excellent corrosion resistance, durability, and can be colored or dyed for aesthetic purposes. 2. Polishing: Polishing is a mechanical process that involves buffing the aluminum sheet to create a smooth and reflective surface. It is commonly used for decorative applications and to enhance the appearance of the metal. 3. Brushing: Brushing involves using abrasive materials or brushes to create a directional grain pattern on the aluminum sheet's surface. This method is often used for architectural applications or to achieve a distinctive textured finish. 4. Powder coating: Powder coating involves applying a dry powder paint to the aluminum sheet's surface and then curing it under heat. This process provides a durable and vibrant finish, offering excellent resistance to weathering, chemicals, and UV rays. 5. Chemical etching: Chemical etching involves using acidic or alkaline solutions to selectively remove the aluminum from the sheet's surface, creating a textured or patterned design. This method is commonly used for decorative purposes or to enhance adhesion for subsequent coatings. 6. Laminating: Laminating involves bonding a protective film or layer onto the aluminum sheet's surface. This method provides added protection against scratches, stains, and other physical damage while also allowing for customization through different film finishes. 7. Sandblasting: Sandblasting uses high-pressure air or water to propel abrasive particles onto the aluminum sheet's surface, creating a textured or matte finish. It is often used to remove impurities, improve paint adhesion, or create a distinctive appearance. These are just a few of the many methods available for surface finishing aluminum sheets. The choice of method depends on the desired appearance, functionality, and specific requirements of the application.

- Q:Can aluminum sheet be used for heat sinks?

- Yes, aluminum sheet can be used for heat sinks. Aluminum has excellent thermal conductivity, making it a suitable material for dissipating heat. The sheet can be designed and fabricated into various shapes and sizes to effectively transfer and dissipate heat from electronic components or other heat-generating devices.

- Q:What is the typical creep resistance of aluminum sheets?

- The typical creep resistance of aluminum sheets varies depending on the specific alloy and temper. Aluminum alloys typically have good creep resistance compared to other metals, especially at lower temperatures. However, the creep resistance of aluminum decreases significantly at higher temperatures. Aluminum sheets with higher alloying elements like copper, magnesium, or zinc tend to have better creep resistance than pure aluminum. Additionally, heat treatment processes such as cold rolling, annealing, or precipitation hardening can enhance the creep resistance of aluminum sheets. In general, aluminum sheets are known for their relatively low creep rates, making them suitable for various applications that require good dimensional stability over extended periods. However, it is important to note that the exact creep resistance of aluminum sheets can vary depending on the specific composition, processing, and operating conditions. Therefore, it is advisable to consult material specifications or conduct specific tests to determine the creep resistance of a particular aluminum sheet.

- Q:Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion. Aluminum is known for its durability and strength, making it resistant to scratches or damage caused by abrasion. However, the level of resistance may vary depending on the specific alloy and thickness of the aluminum sheet. Thicker sheets with higher alloy content tend to provide better resistance against abrasion. Additionally, the surface finish of the aluminum sheet can also play a role in its resistance to abrasion. Overall, aluminum sheets are a reliable choice when it comes to withstanding abrasion in various applications.

- Q:What are the different methods of surface coloring aluminum sheets?

- There are several different methods to surface color aluminum sheets, each with its own advantages and limitations. Some of the most common methods include anodizing, powder coating, and painting. 1. Anodizing: Anodizing is a popular method for coloring aluminum sheets. It involves creating a controlled oxide layer on the surface of the aluminum through an electrochemical process. This oxide layer can be dyed in various colors, providing a durable and long-lasting finish. Anodized aluminum is resistant to corrosion, UV rays, and scratching, making it ideal for outdoor applications. 2. Powder coating: Powder coating is another widely used method for coloring aluminum sheets. It involves applying a dry powder coating to the surface of the sheet, which is then cured in an oven. The powder melts and forms a protective layer that adheres to the aluminum. Powder coating offers a wide range of colors and finishes, and it provides excellent durability, resistance to fading, and protection against scratches. 3. Painting: Painting is a traditional method of coloring aluminum sheets. It involves applying a liquid paint to the surface, which then dries and forms a protective layer. Painting offers a vast array of color options and can be used to achieve different finishes, such as matte, gloss, or metallic. However, painted aluminum sheets may require additional protective coatings to enhance durability and resistance to fading. 4. Cladding: Cladding is a technique that involves applying a thin layer of colored material, such as stainless steel, copper, or composite panels, to the surface of the aluminum sheet. This method allows for a wide range of colors and finishes, and it provides additional protection to the aluminum. Cladding can be used to achieve a unique aesthetic or to enhance the durability of the aluminum sheet. 5. Dye sublimation: Dye sublimation is a specialized method of coloring aluminum sheets that involves transferring designs or images onto the surface using heat and pressure. This process allows for high-resolution prints and vibrant colors, making it popular for decorative and signage applications. Each method of surface coloring aluminum sheets has its own advantages and considerations, such as durability, aesthetics, cost, and application requirements. It is important to carefully evaluate these factors to determine the most suitable method for a specific project.

- Q:how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot/Cold Rolled Stucco Embossed Aluminium Checker Plate 5 bars /3 Bars /1 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords