Wholesale Anodized Aluminum Extrusion Profiles in Color RAL from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Anodized Aluminum Perfile in Color RAL from China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Anodized Aluminum Perfile in Color RAL from China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Anodized Aluminum Perfile in Color RAL from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

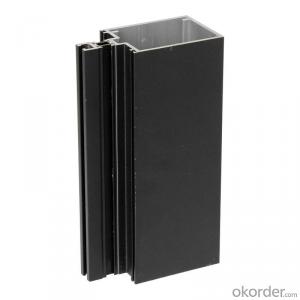

5. Image of Anodized Aluminum Perfile in Color RAL from China

6. Package and shipping of

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles within the construction industry.

- <p>Aluminum profiles offer several advantages in construction, including high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures and facilitates easier installation. Their resistance to corrosion means they require less maintenance and have a longer lifespan compared to steel. Additionally, aluminum profiles can be easily cut, bent, and joined, making them versatile for various applications. However, they have some disadvantages, such as lower thermal conductivity, which can be a concern in temperature-sensitive environments. They are also more expensive than some traditional materials like steel. Lastly, aluminum profiles can dent or deform under heavy loads, which may limit their use in certain structural applications.</p>

- Q: What are the different machining techniques used on aluminum profiles?

- Some of the different machining techniques used on aluminum profiles include milling, drilling, turning, grinding, and tapping. These processes help shape and refine the aluminum profiles to meet specific design requirements and achieve desired dimensions and surface finishes.

- Q: How can the aluminum profile T6 and T5 be distinguished?

- Hardness is generally measured by a Brinell hardness tester. T5 is subjected to high temperature molding and air cooling quenching in the shortest possible time. The T6 is treated with solid solution after artificial aging. So there is a difference between the two. But from the appearance of it is difficult to judge, experienced hands can be used to swing aluminum, roughly judged

- Q: How do aluminum profiles contribute to the reduction of noise pollution?

- Aluminum profiles contribute to the reduction of noise pollution through their inherent properties of sound insulation and dampening. The use of aluminum profiles in various applications, such as windows, doors, and façades, helps to create a barrier against external noise sources. The material's high density and rigidity effectively absorb and block sound waves, minimizing their transmission into indoor spaces. Additionally, aluminum profiles can be combined with sealing and gasketing systems to further enhance their noise reduction capabilities.

- Q: What are the different surface sandblasting options for aluminum profiles?

- Aluminum profiles offer various options for surface sandblasting, each with its own distinctive finish and level of abrasiveness. 1. For a polished or satin appearance, fine sandblasting delicately eliminates surface imperfections, creating a smooth finish on the aluminum profile. This method employs fine-grain sand or abrasive materials. 2. To achieve a rugged texture, coarse sandblasting employs larger-grain sand or abrasives, providing a matte or textured finish on the aluminum surface. This option effectively conceals scratches and blemishes. 3. Glass bead blasting involves propelling small glass beads at high speed onto the aluminum profile's surface. This technique ensures a uniform and visually pleasing matte finish, often desired for its reflectivity. 4. Walnut shell blasting, a gentler approach compared to traditional sandblasting, utilizes ground walnut shells as the blasting media. This technique is suitable for delicate aluminum profiles, effectively removing contaminants and providing a clean, smooth finish. 5. Shot peening is a specialized sandblasting process that involves bombarding the aluminum profile with small metal shots or pellets. Primarily utilized to enhance strength and resistance to fatigue, shot peening focuses on improving the aluminum surface's durability rather than altering its appearance. Considering the specific requirements and desired outcome is crucial when selecting a surface sandblasting option for aluminum profiles. Consulting with professionals in the field can help determine the most suitable method based on the desired finish, level of abrasiveness, and the properties of the aluminum profile.

- Q: Are aluminum profiles capable of being tailored to fit unique design specifications?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements. This customization includes altering dimensions, surface treatments, and shapes to fit the needs of various applications. Manufacturers can cut, bend, and machine aluminum profiles to precise specifications, allowing for a high degree of flexibility in design and functionality. Customization is often possible through processes like extrusion, which allows for the creation of complex profiles that can be tailored to exacting standards.</p>

- Q: Are aluminum profiles suitable for use in electronics manufacturing?

- Yes, aluminum profiles are suitable for use in electronics manufacturing. Aluminum is a lightweight and durable material with excellent thermal conductivity, making it ideal for use in electronic components and enclosures. It also offers good electromagnetic shielding properties. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, making them a popular choice in the electronics industry.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the manufacturing and construction of windows and doors.

- <p>Aluminum profiles for windows and doors come in various types, each serving specific functions and designs. Common types include: 1) Casement profiles, used for side frames and meeting stiles in casement windows; 2) Mullion profiles, for vertical and horizontal structural members in window walls; 3) Transom profiles, used in the top or bottom of windows to support glazing; 4) Sash profiles, forming the main frame of the window sash; 5) Threshold profiles, used at the bottom of doors for weather sealing; 6) Header profiles, supporting the top of a door or window opening; and 7) Specialty profiles, designed for specific architectural needs like corner posts or decorative elements. Each profile is engineered for strength, durability, and compatibility with glazing and浜旈噾閰嶄欢.</p>

- Q: What are the different types of corner connectors used with aluminum profiles?

- There are several different types of corner connectors that are commonly used with aluminum profiles. These connectors are designed to join two or more aluminum profiles together at a corner, allowing for the creation of various structures such as frames, enclosures, and shelving units. One common type of corner connector is the 90-degree angle bracket. This type of connector features a right angle shape, with holes on each side to accommodate screws or bolts for fastening the profiles together. The 90-degree angle bracket is versatile and can be used for a wide range of applications. Another type of corner connector is the 45-degree angle bracket. This connector is similar to the 90-degree angle bracket but is designed to create a 45-degree angle joint between two profiles. It is commonly used in applications where a slanted or angled structure is desired. T-slot corner connectors are another popular choice. These connectors feature a T-shaped slot that allows for easy insertion of the profiles. They are typically used in applications where adjustability and flexibility are important, as they allow for easy repositioning and modification of the structure. Some corner connectors are designed specifically for certain types of profiles, such as the end cap connector. This type of connector is used to cap off the end of a profile, providing a finished look and protecting the profile from damage. In addition to these, there are various other corner connectors available, such as corner gussets, angle plates, and corner brackets. Each type of connector has its own unique features and advantages, making them suitable for different applications and requirements. Overall, the different types of corner connectors used with aluminum profiles provide a wide range of options for joining and assembling structures. These connectors offer strength, stability, and versatility, making them essential components in the construction of various aluminum profile-based projects.

Send your message to us

Wholesale Anodized Aluminum Extrusion Profiles in Color RAL from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords