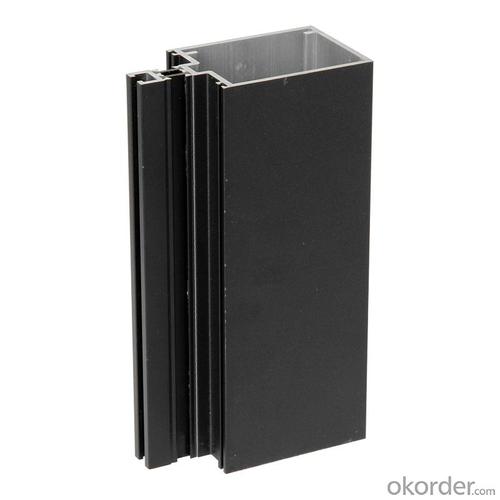

China Made Extruded Aluminum Profiles:Best Selling and Most Welcomed Colorful Anodizing Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: What are the methods to reduce waste from aluminum profiles in construction?

- <p>To minimize waste generated from using aluminum profiles in building construction, consider the following strategies: 1) Accurate planning and design to reduce offcuts. 2) Utilize modular designs to maximize material usage. 3) Implement recycling programs to repurpose leftover profiles. 4) Opt for suppliers that provide aluminum profiles cut to exact specifications. 5) Educate workers on proper handling and waste reduction techniques. 6) Use digital tools for precise cutting to minimize material waste. 7) Encourage the use of aluminum due to its high recyclability and low energy consumption in the recycling process.</p>

- Q: Are aluminum profiles suitable for protective enclosures?

- Yes, aluminum profiles are suitable for protective enclosures. Aluminum is a lightweight yet strong and durable material, making it ideal for constructing protective enclosures. It offers excellent resistance to corrosion, UV rays, and extreme weather conditions, making it suitable for both indoor and outdoor applications. Aluminum profiles can be easily customized and fabricated to meet specific enclosure requirements, such as size, shape, and design. Additionally, aluminum is a non-magnetic material, which can be advantageous in certain applications where magnetic interference needs to be minimized. Overall, aluminum profiles provide a reliable and cost-effective solution for building protective enclosures in various industries, including electronics, telecommunications, automotive, and more.

- Q: Top 10 ranking enterprises of aluminum profiles in China

- 1, aluminum, aluminum (China Aluminum Group, China's aluminum profile ten enterprises, the central management of large state-owned enterprises)2 Asia - South Asia (China well-known trademark, China famous brand, China aluminum enterprise ten, Guangdong Asia Aluminum Factory Co., Ltd.)3 Jianmei aluminum (A Well-Known Trademark in China, Chinese brand, China aluminum enterprise ten, Guangdong Jianmei Aluminum Profile Factory Co., Ltd.)4 Fenglv aluminum material (A Well-Known Trademark in China Chinese, famous brand, famous brand in Guangdong Province, Guangdong famous brand, Guangdong Feng Aluminum Co. Ltd.)5 Zhong Wang aluminum (China famous brand, China well-known trademark, Liaoning famous brand products, China Zhong Wang Holdings Limited)6 (China Hing Fat aluminum brand, A Well-Known Trademark in China, China aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7 Nanshan aluminum (China famous brand, China well-known trademark, China aluminum enterprise ten, Shandong Nanshan aluminum Limited by Share Ltd)8 Zhensheng aluminum (famous brand, China aluminum top ten enterprises, Changsha Shinn Plastic Group Co. Ltd.)9, the court aluminum (China well-known trademarks, China aluminum profile ten enterprises, the court aluminum Polytron Technologies Inc)10 pillars of new materials (China famous brand, China Aluminum ten, Zhejiang pillars, new material Limited by Share Ltd)

- Q: Can aluminum profiles be used for solar power systems?

- Indeed, solar power systems can utilize aluminum profiles. The utilization of aluminum is widespread in the fabrication of solar panels and their supporting frameworks. Its lightweight characteristic, remarkable strength-to-weight ratio, and superior resistance to corrosion make it a favored material. Frequently employed for the framing and installation of solar panels, aluminum profiles offer both structural stability and enduring qualities. Notably, aluminum is effortlessly recyclable, rendering it an environmentally-conscious option for solar power systems.

- Q: Are aluminum profiles recyclable at the end of their useful life?

- <p>Yes, aluminum profiles can be recycled at the end of their lifespan. Aluminum is one of the most recycled materials in the world due to its durability and the energy efficiency of recycling it. The recycling process involves melting the aluminum, which requires significantly less energy than producing aluminum from raw materials. This makes recycling aluminum profiles not only environmentally friendly but also economically viable. The recycled aluminum can be used to produce new aluminum products, contributing to a circular economy.</p>

- Q: What are the minimum thickness specifications for aluminum alloy door and window profiles?

- The main force member without the minimum wall thickness of aluminum profile measured door surface treatment not less than 2, the window is not less than 1.4, piecing material, horizontal and vertical should be determined through calculation, please refer to the specific GB8478:2008 Aluminum Alloy "window"

- Q: Inquire if aluminum profiles can be recycled locally or regionally and how to find more information about it.

- <p>Yes, aluminum profiles can be recycled both locally and regionally. Recycling aluminum is an efficient process that conserves resources and energy. To find out more about local recycling options for aluminum profiles, you can: 1) Contact your local waste management or recycling center to inquire about their services. 2) Search online for recycling facilities in your region that specialize in aluminum. 3) Reach out to local metal scrapyards, as they often accept aluminum for recycling. 4) Check with local environmental agencies or non-profit organizations focused on recycling for guidance and resources.</p>

- Q: What are the bending capabilities of aluminum profiles?

- Due to their inherent properties, aluminum profiles possess exceptional bending capabilities. Aluminum, being a highly malleable metal, can effortlessly assume various shapes without fracturing or breaking, making it an ideal choice for applications that necessitate complex bending or curving. The bending capabilities of aluminum profiles are predominantly influenced by the alloy employed and the specific shape or design being bent. Certain aluminum alloys, such as 6061 or 6063, are commonly utilized for extruded profiles due to their excellent bending properties. These alloys strike a good balance between strength and formability, making them well-suited for bending applications. To bend aluminum profiles, specialized machinery, like a bending machine or a press brake, is typically employed. The profile is meticulously positioned and clamped before pressure is applied to achieve the desired shape. The process can involve multiple passes to accomplish tight or gradual bends. Aluminum profiles can be bent to various angles, ranging from sharp bends to gentle curves, contingent upon the requirements of the application. The bending radius, denoting the minimum radius at which the profile can be bent without causing deformation, is dependent on the profile's thickness, alloy, and temper. Thinner profiles generally possess smaller bending radii compared to thicker ones. It is crucial to note that excessive bending or surpassing the material's capabilities can result in cracking or permanent deformation. Consequently, it is imperative to consider the specific bending requirements and seek guidance from experts or manufacturers to ensure adherence to proper bending techniques and limitations. In conclusion, aluminum profiles exhibit exceptional bending capabilities, facilitating the creation of intricate and customized shapes. Their versatility and formability have made them a favored option in industries such as construction, automotive, aerospace, and furniture manufacturing.

- Q: Are aluminum profiles suitable for use in aerospace structural components?

- Indeed, aerospace structural components can indeed benefit from the utilization of aluminum profiles. Aluminum, given its lightweight and robust nature, proves to be an optimal selection for aerospace applications that prioritize weight reduction. Moreover, it boasts a commendable strength-to-weight ratio, exceptional resistance to corrosion, and remarkable malleability, thereby enabling the construction of intricate shapes and structures. Furthermore, the versatility of aluminum profiles is evident in their effortless integration through diverse methods such as welding, riveting, or adhesive bonding, thereby enabling their adaptability in the assembly of aerospace structural components. In summary, the amalgamation of its exceptional properties and ease of manufacturing renders aluminum profiles an apt choice for aerospace structural components.

- Q: Are aluminum profiles suitable for medical equipment and devices?

- Certainly, medical equipment and devices can indeed benefit from the use of aluminum profiles. Aluminum, being a versatile material, offers numerous advantages in the field of medical applications. Firstly, its lightweight nature renders it highly suitable for portable medical devices, thereby facilitating easy transportation, particularly in urgent situations. Moreover, the corrosion-resistant properties of aluminum are of utmost importance in maintaining the sterility and cleanliness of medical equipment. Furthermore, the material's durability allows it to withstand harsh environments and endure regular cleaning and sterilization procedures. Additionally, the adaptability of aluminum profiles enables effortless customization and fabrication into various shapes and sizes, thereby catering to diverse medical device designs. In conclusion, the exceptional characteristics of aluminum make it a dependable and appropriate choice for medical equipment and devices.

Send your message to us

China Made Extruded Aluminum Profiles:Best Selling and Most Welcomed Colorful Anodizing Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords