Decorative Aluminum Metal Sheets AA1060 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA1060 D.C Quality Used for Construction Description

Aluminum Sheets AA1060 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA1060 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

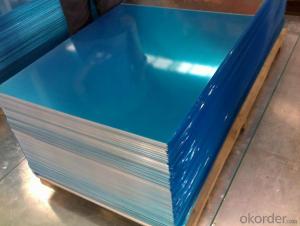

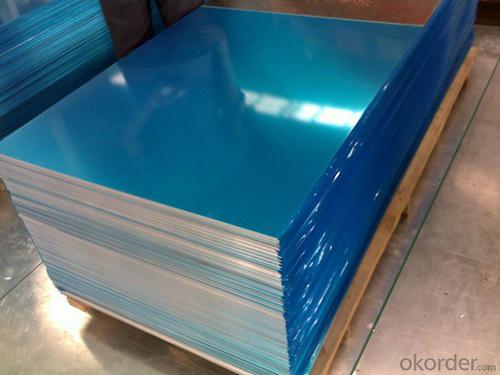

3.Aluminum Sheets AA1060 D.C Quality Used for Construction Images

4.Aluminum Sheets AA1060 D.C Quality Used for Construction Specification

Alloy | AA1060 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1060 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1060 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1060 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum sheet be painted?

- Yes, aluminum sheet can be painted. However, it is important to properly prepare the surface by cleaning, sanding, and priming it before applying any paint. This will ensure better adhesion and durability of the paint on the aluminum sheet.

- Q: Can aluminum sheets be used for solar panels?

- Solar panels can indeed utilize aluminum sheets. Aluminum is widely employed in the manufacturing of solar panels due to its exceptional properties. Its lightweight nature, durability, and resistance to corrosion make it well-suited for enduring diverse weather conditions. Moreover, aluminum boasts excellent electrical conductivity, a crucial element for efficient energy generation in solar panels. By incorporating aluminum sheets, solar panels can guarantee longevity and optimal performance, all while diminishing the panels' overall weight and cost.

- Q: Can aluminum sheets be used for electrical conductors?

- Aluminum sheets have the capability to function as electrical conductors. Despite being less efficient than copper, aluminum demonstrates good electrical conductivity. Nevertheless, owing to its lightweight properties, affordability, and resistance to corrosion, aluminum is frequently employed in various electrical applications. It finds extensive use in power distribution lines, wiring systems, and electrical equipment.

- Q: Can aluminum sheets be embossed or engraved?

- Yes, aluminum sheets can be embossed or engraved.

- Q: Can aluminum sheets be perforated for ventilation purposes?

- Indeed, ventilation purposes can be accomplished by perforating aluminum sheets. The process of perforating involves the creation of minute holes or designs on the sheet to facilitate the flow of air and ventilation. This method finds widespread usage in diverse industries like construction, automotive, and manufacturing. Perforated aluminum sheets provide numerous advantages for ventilation objectives, including improved air circulation, temperature regulation, and moisture management. The size, shape, and arrangement of the perforations can be tailored to meet specific ventilation needs. Furthermore, perforated aluminum sheets possess attributes such as lightness, robustness, and resistance to corrosion, rendering them highly suitable for applications that demand both ventilation and structural integrity.

- Q: Can the aluminum sheets be used for manufacturing solar panel frames?

- Yes, aluminum sheets can be used for manufacturing solar panel frames. Aluminum is a commonly used material in the solar industry due to its lightweight, durability, and corrosion resistance. It is an ideal choice for solar panel frames as it provides structural support while being able to withstand various weather conditions. Additionally, aluminum is easily recyclable, making it an environmentally friendly option for solar panel manufacturers. Overall, aluminum sheets are a suitable material for manufacturing solar panel frames.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- white glue will work if you dilute it 50% with water... they also sell an adhesive in craft stores for gluing down gold leaf... and of course Bare-Metal sells foil with an adhesive backing.... at one time they also sold a foil adhesive...

- Q: Are aluminum sheets suitable for chemical filtration applications?

- Yes, aluminum sheets are suitable for chemical filtration applications. Aluminum is resistant to corrosion, making it an ideal material for filtering chemicals. It is also lightweight and has high thermal conductivity, allowing for efficient heat transfer during filtration processes.

- Q: What are the aluminum plates for?

- Defense (cover containing polyethylene moistureproof layer of kraft paper embossing aluminum alloy), special mould. The tensile aluminum alloy aluminum coated aluminum. Special stamping. Electronic gasket aluminum, alloy aluminum alloy electric radiator. Special aluminum curtain wall coating. (fluorocarbon, polyester) aluminum coil, aluminum coil, special signs aluminum plate, color coated aluminum sheet, aluminum ceiling coating, aluminum plate, aluminum plate pattern, embossing aluminum / aluminum (pointer type, orange peel pattern, diamond, five ribs, aluminum strip). Aluminum wire and cable, transformer Using aluminum strip, aluminum foil, pressure type aluminum corrugated corrugated aluminum plate. Color coating, special aluminum plate, aluminum plate cable tray, material: 1100.1200.1050A.1060.1070.1080.1145.2A11.3003.3A21.3004.3005.3104.3105.LF21.5A02.5A05.5005.5754.5052.5083.5082.5A03.6061.6063.6082.8011. material; H111.H112.H18.H26.H16.H22.H32.H34.H36.H14.H24.H12.T4.T5.T6.O.F state can meet the requirements of customers

Send your message to us

Decorative Aluminum Metal Sheets AA1060 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords