Sheets of Aluminum AA1050 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA1050 D.C Quality Used for Construction Description

Aluminum Sheets AA1050 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA1050 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

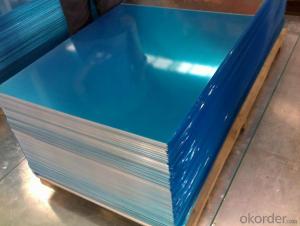

3.Aluminum Sheets AA1050 D.C Quality Used for Construction Images

4.Aluminum Sheets AA1050 D.C Quality Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1050 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1050 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1050 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: How do you join aluminum sheets together?

- There are several methods to join aluminum sheets together, depending on the specific application and desired strength of the joint. Here are some common techniques: 1. Welding: Aluminum can be welded using various methods such as gas tungsten arc welding (GTAW or TIG), gas metal arc welding (GMAW or MIG), or even laser welding. These processes involve melting the aluminum at the joint and adding a filler material to create a strong bond. Welding offers excellent strength and durability but requires skill and appropriate equipment. 2. Riveting: Rivets can be used to fasten aluminum sheets together. This method involves drilling holes through the sheets and using a rivet gun to insert and deform a rivet, creating a secure joint. Riveting is relatively simple and quick, but it may not provide the same strength as welding. 3. Adhesive bonding: Industrial adhesive bonding is a popular method to join aluminum sheets. Specialized adhesives formulated for aluminum bonding are applied to the surfaces, which then cure and form a strong bond. Adhesive bonding is advantageous as it distributes stress evenly and can join dissimilar materials. However, it may not be suitable for high-temperature or high-stress applications. 4. Mechanical fasteners: Screws, bolts, or nuts can be used to fasten aluminum sheets together. This method involves drilling holes and using fasteners to secure the sheets. Mechanical fasteners provide good strength and allow for disassembly if needed. However, they may require additional maintenance and can cause stress concentrations around the holes. 5. Clinching: Clinching is a cold joining method where aluminum sheets are pressed together using a punch and die. The process deforms the materials and creates a mechanical interlock, forming a strong joint. Clinching is a quick and cost-effective method, but it may not be suitable for thin or highly rigid sheets. Ultimately, the choice of joining method depends on factors such as the required strength, aesthetics, cost, and ease of fabrication. It is recommended to consult with a qualified professional or follow specific guidelines to ensure a successful and reliable joint.

- Q: Describe the steps involved in installing aluminum sheets on a roof.

- <p>Installing aluminum sheets on a roof involves several key steps: 1) Inspect the roof structure to ensure it can support the new material. 2) Remove any existing roofing material. 3) Install roof underlayment to protect against moisture. 4) Position the first aluminum sheet at the lowest point of the roof, aligning it with the eaves. 5) Secure the sheet using clips or screws, ensuring a watertight seal. 6) Continue installing sheets up the roof, overlapping each by at least 2 inches for a secure fit. 7) Cut and fit sheets around vents, pipes, and other roof protrusions. 8) Install flashing and trim to finish edges and seal the roof. 9) Check for proper alignment and secure all fasteners. 10) Clean up debris and inspect the installation for any gaps or leaks.</p>

- Q: Can aluminum be either conductive or magnitized?

- Aluminum is conductive. In fact at one point in time it was used as an alternative to copper wiring for home electrical wiring. (There were problems, so it is no longer used).

- Q: Can aluminum sheets be used for electrical busbars?

- Yes, aluminum sheets can be used for electrical busbars. Aluminum is a highly conductive material that has good electrical and thermal conductivity properties. It is also lightweight and cost-effective compared to other metals like copper. However, there are certain considerations when using aluminum sheets for busbars. Aluminum has higher resistance compared to copper, so larger cross-sectional areas may be required to compensate for this. Additionally, proper insulation and joint connections must be implemented to prevent any potential galvanic corrosion issues between the aluminum busbars and other metals in the electrical system. Overall, aluminum sheets can be a suitable choice for electrical busbars, but the specific application requirements and design considerations should be carefully evaluated to ensure optimal performance and safety.

- Q: only aluminum source i have is mountain dew cans any way to turn them quickly into a powder?or any other ideas?

- www.okorder sells both iron oxide and aluminum powder. Their CH0174 aluminum makes a great thermite. Way easier to just buy the stuff by the pound than than grinding aluminum cans or breaking apart etchasketches.

- Q: What is the typical tensile strength of aluminum sheets?

- The typical tensile strength of aluminum sheets can vary depending on the specific grade or alloy being used. Generally, the tensile strength of aluminum sheets ranges from 20,000 to 50,000 pounds per square inch (psi). However, it is important to note that this is a broad range, and the exact tensile strength can be influenced by factors such as the thickness of the sheet, the manufacturing process, and any additional treatments or coatings applied to the aluminum. Therefore, it is recommended to consult the specifications provided by the manufacturer or supplier for accurate information on the tensile strength of a specific aluminum sheet.

- Q: Is it possible to incorporate recycled aluminum windows into a construction or renovation project?

- <p>Yes, you can use recycled aluminum windows in your project. Recycled aluminum windows are not only environmentally friendly but also offer similar performance to new aluminum windows. They are durable, lightweight, and maintain good thermal efficiency. When selecting recycled aluminum windows, ensure they meet the required quality standards and are suitable for your project's specifications. It's also important to consider the condition of the windows and any necessary refurbishment or maintenance they might require.</p>

- Q: 1995 s10 I took this whole thing apart and marked and labled everything. Now i have an aluminum head sitting on a bucket that was spraying water right from the head gasket but the head gasket is in perfect shape, and there are no cracks i can see on the head. One more thing, the truck would not start up with water in it, but it would when it was drained, like it was blocking the spark or something. yes it did overheat has this ever happened to anyone else, and any ideas? Thank you.

- its not the head gasket, thats what i had thought too. its actually the intake manifold gasket. GM did not design them to resist DEXCOOL, so they disintegrate in a few years. Gm had a lawsuit concerning this. You need to remove the intake manifold if you haven't already and replace the gaskets with quality gaskets from autozone. You will need to remove the distributor, so be sure to mark it. good Luck might be a good idea to replace all hoses, and water pump while your at it

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: How does the surface treatment affect the corrosion resistance of aluminum sheet?

- Surface treatment can significantly enhance the corrosion resistance of aluminum sheets. Processes such as anodizing, chemical conversion coating, and painting create protective layers on the surface, which act as barriers against corrosive agents. These treatments not only improve the durability and lifespan of the aluminum sheet but also enhance its ability to withstand harsh environmental conditions and prevent the occurrence of corrosion.

Send your message to us

Sheets of Aluminum AA1050 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords