Aircraft Grade Aluminum Sheets AA8006 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA8006 D.C Quality Used for Construction Description

Aluminum Sheets AA8006 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA8006 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

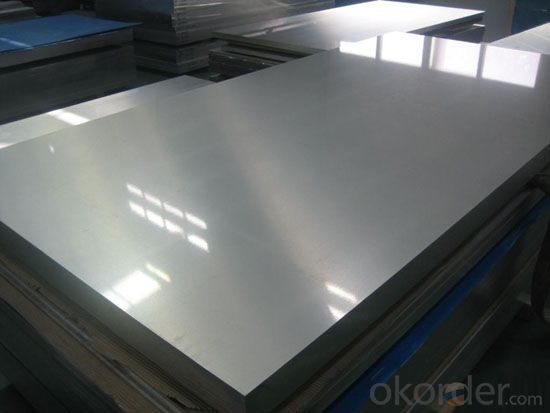

3.Aluminum Sheets AA8006 D.C Quality Used for Construction Images

4.Aluminum Sheets AA8006 D.C Quality Used for Construction Specification

Alloy | AA8006 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA8006 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA8006 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA8006 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What is the density of aluminum plate?

- The density of aluminum plate is: 2.7 * 10^3Aluminium plate is usually divided according to the following two kinds:1., according to the alloy composition is divided into:High pure aluminium plate (rolled by high purity aluminium with more than 99.9 content)Pure aluminium plate (basically rolled from pure aluminium)Aluminum alloy (composed by aluminum and alloy auxiliary usually aluminum copper, aluminum manganese, silicon aluminum, aluminum and magnesium, etc.)Composite aluminum brazing sheet (or special purpose aluminum material composite material through a variety of means)Aluminum aluminum (aluminum coated outside the thin aluminum sheet used for special purposes)

- Q: I am using Reeves Acrylic Colour Set and I plan on painting on Heavy Duty Ralphs Brand Aluminum Foil. Will the paint be able to go on the foil well? Tips? Thank you.

- i use aluminum foil to mix colors on and when it dries it DOES stick, however, it will scratch off really easy. just try experimenting. what do u need the foil for? maybe you can try the aluminum foil leaves? the flakes that you put ontop on the art instead of under it. that way you can glue it on and dont have to worry about it scratching off. foil looks beautiful on paintings :) how it turns out great

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets differs based on the specific alloy employed. On average, aluminum exhibits a coefficient of thermal expansion of around 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). Consequently, with each degree rise in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It should be emphasized that this figure might vary slightly among diverse grades and alloys of aluminum.

- Q: What type of aluminum plate does it contain?

- 1 * * * series aluminum sheet: stands for 1050, 1060, 1100. In all series, the 1 x x series belongs to a series with the largest amount of aluminum. Purity can reach more than 99%.2 * * * series aluminum sheet: 2A16 (LY16) and 2A06 (LY6). The characteristics of 2 * * * series of aluminum is high hardness, which belongs to the copper content is the highest, about 3-5%.

- Q: How to mix solid aluminium sheet with solid copper sheet (using heat?) to make a compound.

- I'm not sure if I correctly understand your question - that is, whether you're asking how to physically fasten copper and aluminum pieces together, or of you're asking how to make intermetallic compounds of copper and aluminum. Since you did mention a compound, though, I'm guessing the latter. Copper and aluminum do react to form a number of intermetallic compounds. Among these are Al4Cu9, AlCu, and Al2Cu (see first reference below). These are referred to as aluminides of copper, and may be prepared by melting the two metals together in the proper ratio by weight and cooling slowly. For example, Al2Cu (also called CuAl2) may be prepared by melting a mixture containing 96% aluminum and 4% copper (see second reference below). Note that a protective inert atmosphere is desirable for any work of this sort to prevent oxidation. CORRECTION: The compound CuAl2 contains about 54% copper and 46% aluminum (NOT as above). It's the 2000 series aluminum alloys which contain around 4% copper, and it is the precipitation of CuAl2 during heat treatment which makes them hardenable. The final sentence in the second paragraph above should read: For example, Al2Cu (also called CuAl2) may be prepared by melting a mixture containing 46% aluminum and 54% copper (see second reference below).

- Q: 4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The square and the thickness are multiplied, and then multiplied by the density is the weight, and then by weight conversion on it

- Q: Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed. Embossing is a process that creates a raised or sunken design on a material's surface. Aluminum is a versatile material that can be easily manipulated, including being embossed. Embossing aluminum sheets can be done using various methods, such as heat embossing or using embossing tools and machines. The embossing process adds texture and dimension to the aluminum sheets, enhancing their appearance and making them suitable for various applications such as decorative purposes, signage, nameplates, or even for adding texture to automotive or architectural accents.

- Q: Is it feasible to use aluminum sheets for constructing exteriors of buildings in regions susceptible to earthquakes?

- <p>Aluminum sheets can be used for building exteriors in earthquake-prone areas, but they must be properly engineered and installed. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it's crucial to ensure that the aluminum is reinforced with a robust structural system that can distribute the forces during an earthquake. The design must also comply with local building codes and seismic regulations. It's recommended to consult with structural engineers and architects experienced in earthquake-resistant design to ensure the safety and durability of the construction.</p>

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- 7075 T6 hardness in 150HB, hardness is highestUsually 6061 and 6063 can be common

- Q: What is the typical fatigue life of aluminum sheets?

- The typical fatigue life of aluminum sheets can vary depending on various factors such as the alloy used, the thickness of the sheet, the loading conditions, and the manufacturing process. However, aluminum sheets generally have a relatively high fatigue life compared to other materials, typically ranging from 10^5 to 10^7 cycles.

Send your message to us

Aircraft Grade Aluminum Sheets AA8006 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords