Aluminum Decorative Metal Sheets AA3005 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA3005 Used for Constrcution Description

Aluminum Sheets AA3005 Used for Constrcution has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA3005 Used for Constrcution is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA3005 Used for Constrcution

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

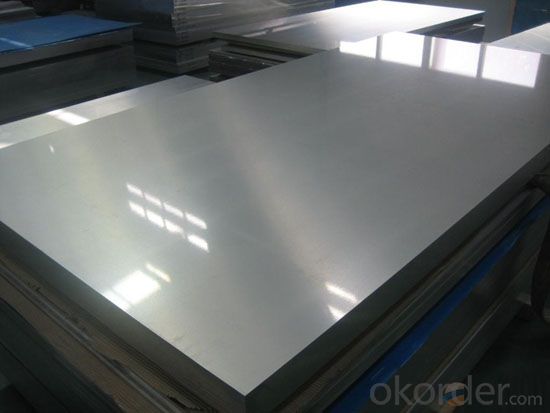

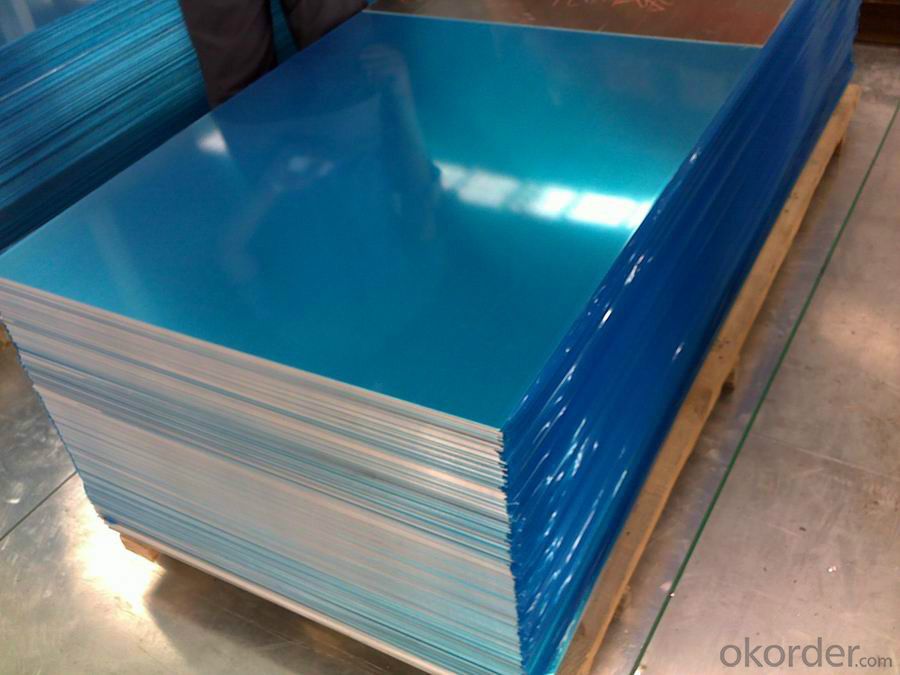

3.Aluminum Sheets AA3005 Used for Constrcution Images

4.Aluminum Sheets AA3005 Used for Constrcution Specification

Alloy | AA3005 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA3005 Used for Constrcution

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA3005 Used for Constrcution.

B.When will you deliver the products?

Aluminum Sheets AA3005 Used for Constrcution will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: For my chem class that I just barely started taking, we're making bohr models. Even though my teacher explained it, I still dont get the concept of it all, like how the protons are lined up in their inner circle and the outer circles. I get everythign else about atoms except how they're actually made up lol. Maybe someone on here can explain it to me? I hope so because i have to make a model for it for friday.The element I'm asigned is aluminum btwYour help is greatly appreciated!

- An atom is made up of protons. electrons and neutrons. The protrons and neutrons are located in the nucleus, while the electrons are located on the shells outside the nucleus. Think of the shells as orbits, orbits which can only hold a certain amount of electrons. In the Bohr's model of Aluminum there will be 2 elctrons on the first shell, 8 electrons on the second shell, and 3 electrons on the last shell.

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength of 101 aluminum sheets can vary depending on various factors such as manufacturing process, heat treatment, and specific alloy composition. However, generally speaking, 101 aluminum sheets have a tensile strength of approximately 27,000 to 42,000 pounds per square inch (psi). It is important to note that this range is an approximation and actual tensile strength values may differ slightly. It is recommended to refer to the specific manufacturer's data sheet or conduct further testing to determine the precise tensile strength of 101 aluminum sheets.

- Q: Are aluminum sheets resistant to impact and vibration?

- Yes, aluminum sheets are generally resistant to impact and vibration. Aluminum is known for its high strength-to-weight ratio, making it a durable and lightweight material. It has good mechanical properties, including excellent resistance to impact and vibration. Aluminum sheets are often used in applications that require protection against impact and vibrations, such as automotive parts, aircraft structures, and building facades. Additionally, aluminum can be alloyed with other elements to enhance its impact resistance and reduce vibrations. Overall, aluminum sheets are a reliable choice for withstanding impact and vibration forces.

- Q: What are the distinctions among various grades of aluminum sheets?

- <p>Yes, there are differences between different grades of aluminum sheets. These differences are primarily based on the alloy composition, which affects properties such as strength, formability, and corrosion resistance. For instance, 1000 series aluminum is pure and soft, making it ideal for general purposes. 2000 series is harder and stronger, often used in aerospace applications. 3000 series is known for its high resistance to corrosion and is used in marine applications. 5000 series offers good strength-to-weight ratio and is used in structural applications. 6000 series is known for its strength and is used in construction and industrial applications. Each grade has specific uses based on its unique characteristics.</p>

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a safe and commonly used material for food packaging and cooking utensils due to its non-toxic properties, resistance to corrosion, and ability to maintain food quality and freshness.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: i added aluminum sulfate to the soil from the bag with out mixing it with water and my hydrangeas look very sad. It burned them i guess... What is best thing to do to take some of it out or all if i can? will adding large amounts of water to the soil help it clear or will it make it worse? please before they die!!!10points!!!

- Aluminum sulfate lowers the pH of soil (increases the acidity). To increase the pH, you need to add lime. The ideal pH for most plants is around neutrality, or pH = 7. I can't tell you how much lime to add, since I don't know how much aluminum sulfate you added. Try to add roughly the same amount as the aluminum sulfate and see if that helps. Overwatering may help some, as it will leach out some of the acid.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum... airplanes are not chrome plated... weight and the difficulty of electro-plating an entire aircraft are the reasons Could likely get some dissimilar metal corrsosion problems as well... Polished aluminum airplanes are absolutely beautiful, but it takes an incredible amount of work to get it that way, and a nearly equal amount of work to keep it up... plan on spending lots of time, money or both...

- Q: Can aluminum plate protect against radiation?

- Two. A brief introduction to radiation:Radiation refers to electromagnetic energy from the source part from the field source and transmitted, then return to the source, energy by electromagnetic waves or particles (such as the Alfa particle, beta particle) in the form of outward diffusion. All objects in nature, as long as the temperature is above zero degrees of absolute temperature, send the heat continuously in the form of electromagnetic waves and particles. This way of transmitting energy is called radiation. The radiation energy radiates straight from the source outward in all directions. The energy emitted by an object through radiation is called radiant energy. The radiation was calculated by roentgen / hour (R). One important feature of radiation is that it is "peer"". A body can radiate radiation to a second object, and at the same time a radiation to a target, regardless of the temperature of the object (gas). The term is commonly used in ionizing radiation. Radiation itself is a neutral term, but radiation from certain substances can be harmful.

- Q: How do you bend aluminum sheets?

- To bend aluminum sheets, you will need a few tools and the right technique. Here is a step-by-step guide on how to bend aluminum sheets: 1. Gather the necessary tools: You will need a metal brake, which is a specialized tool used for bending metal sheets, and a straight edge, such as a ruler or a piece of wood. 2. Measure and mark the bending line: Determine where you want to make the bend on the aluminum sheet and use a measuring tape to mark the line. Make sure the line is straight and accurate. 3. Position the aluminum sheet: Place the aluminum sheet on the metal brake, aligning the marked bending line with the edge of the brake. Ensure the sheet is secure and won't move during the bending process. 4. Adjust the metal brake: Depending on the thickness of the aluminum sheet, adjust the metal brake to the appropriate bending angle. This can typically be done by loosening or tightening the clamps or screws on the brake. 5. Bend the aluminum sheet: Apply pressure on the metal brake, slowly bending the aluminum sheet along the marked bending line. Start from one end and work your way towards the other, ensuring a smooth and even bend. 6. Check the bend: After bending, double-check the angle and alignment to ensure it matches your desired specifications. If necessary, make any adjustments before proceeding. 7. Repeat if needed: If you need to make multiple bends on the aluminum sheet, repeat the process for each one. Take your time and be patient to achieve the desired results. It's important to note that the thickness and type of aluminum sheet may require adjustments to the bending technique. Thicker sheets may need more pressure or multiple passes to achieve the desired bend. Always refer to the specific instructions and recommendations provided by the manufacturer of your metal brake for best results.

Send your message to us

Aluminum Decorative Metal Sheets AA3005 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords