Aluminum Extrusion Profiles Los Angeles for Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

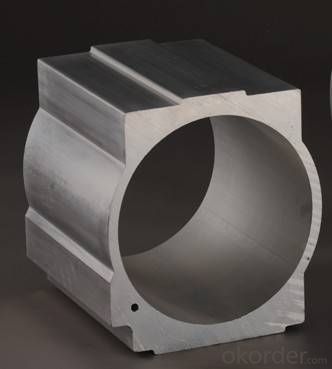

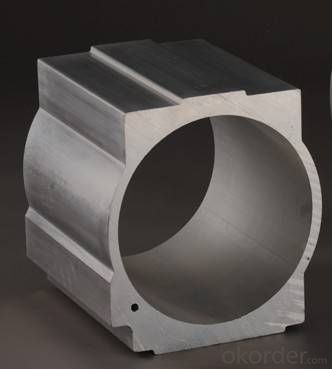

1. Structure of Aluminium Extrusion Profiles For Motor Cylinder Shell Description

Aluminium Extrusion Profiles For Motor Cylinder Shell is one semi-finished aluminium material. It is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Extrusion Profiles For Motor Cylinder Shell

Aluminium Extrusion Profiles For Motor Cylinder Shell | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Extrusion Profiles For Motor Cylinder Shell

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Extrusion Profiles For Motor Cylinder Shell

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Extrusion Profiles For Motor Cylinder Shell

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Aluminium Extrusion Profiles For Motor Cylinder Shell

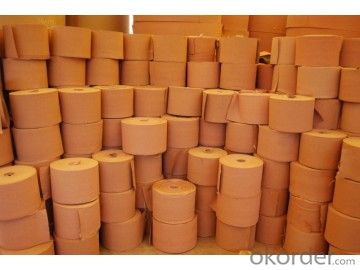

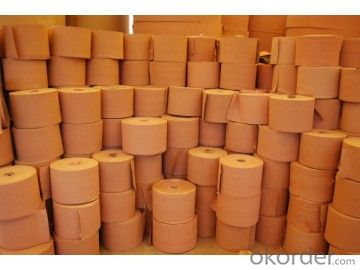

7. Package and shipping of Aluminium Extrusion Profiles For Motor Cylinder Shell

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What specific coatings or finishes are necessary for aluminum profiles to withstand cold weather conditions?

- <p>In cold climates, aluminum profiles may require special coatings or finishes to enhance durability and resistance to corrosion. These can include anodizing, which forms a protective oxide layer on the aluminum surface, or powder coating, which provides a hard, durable finish. Additionally, thermal breaks may be incorporated into the design to reduce heat transfer and prevent condensation. It's crucial to select the right finish based on the specific environmental conditions and the intended use of the aluminum profile.</p>

- Q: What are the fire safety regulations for aluminum profiles?

- The fire safety regulations for aluminum profiles vary depending on the specific application and building codes in each jurisdiction. However, in general, aluminum profiles used in construction must meet certain fire resistance standards to ensure safety. This may include factors such as the thickness and composition of the aluminum, the use of fire-resistant coatings or insulation, and compliance with international fire safety standards like ASTM E119 or EN 13501. It is important to consult local building codes and regulations to determine the specific fire safety requirements for aluminum profiles in a particular area.

- Q: What are the noise reduction properties of aluminum profiles?

- Due to their inherent characteristics, aluminum profiles exhibit outstanding noise reduction properties. The effective material for reducing noise transmission is aluminum, thanks to its high density and rigidity. When utilized in structural applications, aluminum profiles have the ability to dampen and absorb sound waves, thereby limiting their propagation and decreasing noise levels. The incorporation of additional noise-reducing features is made possible by the versatility of aluminum profiles. To further enhance their noise reduction properties, aluminum profiles can be combined with insulating materials such as foam or rubber. This combination creates a barrier that absorbs sound waves, preventing their passage and minimizing noise transmission. Furthermore, the reduction of noise is aided by the ability of aluminum profiles to be designed with intricate shapes and structures. By employing innovative designs like ribbing or perforations, the profiles can effectively scatter and disrupt sound waves, resulting in reduced noise levels. Additionally, the noise reduction capabilities of aluminum profiles can be enhanced by anodizing or coating the surfaces with sound-absorbing materials. These surface treatments contribute to the absorption and dissipation of sound energy, leading to a reduction in noise resonance and an improvement in overall acoustic performance. In conclusion, due to their density, rigidity, and versatility, aluminum profiles possess excellent noise reduction properties. When combined with insulating materials, innovative designs, and surface treatments, aluminum profiles are capable of effectively reducing noise transmission, making them a suitable choice for applications where noise control is of utmost importance.

- Q: Can aluminum profiles be used in exhibition or trade show displays?

- Exhibition or trade show displays can incorporate aluminum profiles, which are lightweight, durable, and versatile. These profiles are an excellent option for constructing exhibition displays due to their ability to be easily assembled and disassembled, enabling swift setup and dismantling at trade shows. Furthermore, aluminum profiles can be tailored to produce diverse shapes and sizes to accommodate various exhibition booth designs. They can also be effortlessly combined with other materials like fabric, glass, or acrylic panels to create visually appealing and professional displays. Ultimately, aluminum profiles present a practical and cost-effective solution for exhibition or trade show displays.

- Q: Can aluminum profiles be used for swimming pool covers?

- Indeed, swimming pool covers can indeed utilize aluminum profiles. Aluminum, being both lightweight and long-lasting, is impervious to corrosion and can endure exposure to water and a range of weather conditions. Aluminum profiles can be employed to build the structure of swimming pool covers, granting them stability and reinforcement. Moreover, they can be used to fabricate sliding or folding mechanisms, allowing for effortless opening and closing of the covers. Furthermore, these aluminum profiles can be enhanced in terms of appearance and safeguarded against corrosion through powder coating or anodization. In summary, owing to their robustness, endurance, and adaptability, aluminum profiles are widely favored when it comes to swimming pool covers.

- Q: What are the surface finishes available for aluminum profiles?

- Some common surface finishes available for aluminum profiles include anodizing, powder coating, polishing, brushing, and chemical etching.

- Q: How are the aluminum and aluminum sections joined?

- Method for connecting aluminum section and aluminium section bar:The use of aluminum connecting piece.Welding: aluminum can be welded, and can be realized by argon arc welding or MIG welding. What welding process is adopted, depending on the specific workpiece.Cementation: bonding (bonding) is a method of making two adhesive joints by utilizing mechanical binding force, physical adsorption force and chemical bonding force produced on the join surface.

- Q: This question asks whether aluminum profiles can be utilized for creating interior partitions and seeks reasons for their suitability.

- <p>Yes, aluminum profiles can be used for interior partitions. They are favored for several reasons: they are lightweight yet strong, offering durability and stability. Aluminum profiles are also resistant to corrosion, which makes them suitable for various environments. Their ease of installation and low maintenance requirements make them cost-effective. Additionally, they can be easily customized to fit various design needs, and their recyclability makes them an environmentally friendly choice.</p>

- Q: This question asks about the characteristics of aluminum profiles, specifically whether they are lightweight and easy to handle.

- <p>Yes, aluminum profiles are known for their lightweight nature and ease of handling. They are made from aluminum, which is a lightweight metal with a low density. This makes aluminum profiles ideal for applications where weight is a concern, such as in construction, automotive, and aerospace industries. Additionally, their lightweight characteristic also contributes to their ease of handling, as they can be easily maneuvered and installed without requiring heavy machinery or excessive manpower.</p>

- Q: Can aluminum profiles be used for creating display systems?

- Display systems can indeed be created using aluminum profiles. Aluminum, a versatile and lightweight material, finds extensive application across various industries, including the display and signage sector. When it comes to constructing display systems, aluminum profiles offer numerous advantages. To begin with, aluminum boasts exceptional durability and resistance to corrosion, rendering it suitable for both indoor and outdoor display purposes. It can withstand diverse environmental conditions, ensuring the display system's long-lasting nature. Furthermore, aluminum profiles allow for easy customization. They can be extruded into various shapes and sizes, providing flexibility in design. This facilitates the creation of distinctive and attention-grabbing display systems that cater to specific requirements. Moreover, the assembly and disassembly of aluminum profiles are effortless, which proves advantageous for display systems that necessitate frequent adjustments or transportation. Typically, they come equipped with a straightforward slot and groove system or other connecting mechanisms, simplifying installation and maintenance. Additionally, aluminum profiles can be anodized or powder-coated to attain decorative or protective finishes. This permits customization in terms of color and texture, elevating the aesthetics of the display system. Lastly, aluminum profiles deliver structural stability while remaining lightweight. This makes them ideal for extensive displays or installations where weight becomes a concern. To summarize, aluminum profiles stand as an exceptional choice for creating display systems due to their durability, customizability, ease of assembly, and aesthetic appeal.

Send your message to us

Aluminum Extrusion Profiles Los Angeles for Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords