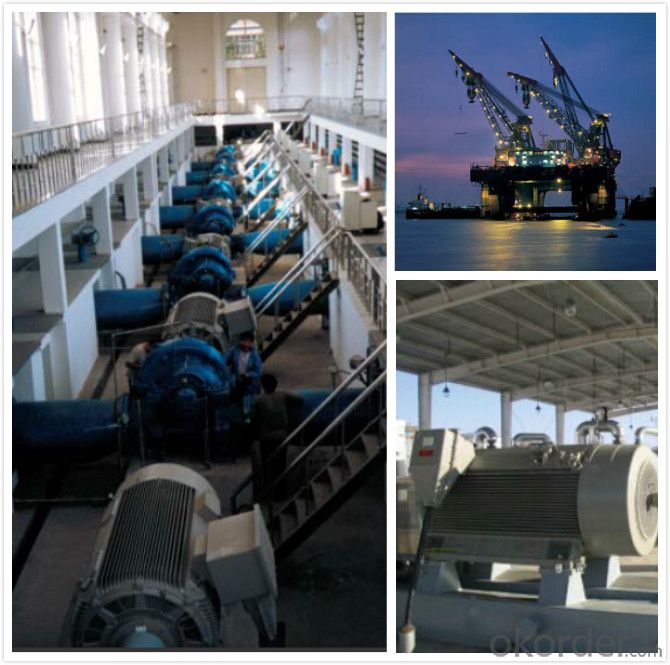

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q:and act as a brake or actuator? I realize an electric motor can act as a brake but can its position be locked solid?

- Stepping motors have a holding torque. Otherwise you are hoping for the gears (think worm gear) to do it. There are motors with a brake operated by a solenoid. Take note of some electric wheel chairs, but also gear drives with solenoid brake are in the industrial market. Some speed controllers have an output to operate this brake.

- Q:What cable is used to connect 3 phase Ac motor to Variable drive?

- Various okorder /

- Q:fan motor on our ac central unit went out we replaced it but now it wont throw cold air and seems as it wants to cut of or pick up speed .what could it be..

- could is not spelled like that

- Q:I have a 98 BMW 7 series. The AC Blower needs to be replaced. Does the mechanic have to remove the dashboard to install a new one? Or can the replacement motor be installed through the front engine bay?

- It is not easy, but the AC blower motor should be accessible without removing the dashboard. You may have to stand on your head to do, it, but work at it until you get the old AC blower out.

- Q:i need to use an electric motor and i need to know how to change it to dc

- Hold on a minute. If you're thinking of running an AC electric motor on DC, forget it. It won't work. If the power available is DC, you need a DC motor that runs on the voltage you have available. Most common, single-phase, AC motors require 120 volts. You'd better regroup and reconsider your strategy.

- Q:ok, it is a 1977 old motor home, the kind that looks like a van in the front but has a over cab bed area. so it is about 15' long and about 7' wide. It sits in the Arizona sun all day long and right now it is close to 110 degrees. so how much per month does this raise my electric bill?it is not very insulated and is being lived in so it is running alot.

- I doubt a AC that size will keep the home cool in that climate, so it will run continuously. Look up the current or wattage of the unit. It will be about 600 watts or 5 amps. The next thing you need is the cost of electricity in your area. Guessing at 10? per kW-hr.. 600 watts x 24 hours/day x 30days/month = 432000 watt hours or 432 kW-hrs/month 432 kW-hrs/month x $0.10 per kw-hr = $43 per month. .

- Q:How heavy is a 20 amp motor and what is it rated at in horsepower?

- Motors tend to have nameplates that give you the HP. This will be the output power. You have given an input current but not even mentioned the voltage. With the voltage and current, you could estimate the output if you guess at the efficiency.

- Q:What voltage does it run on? And if I used a motor to spin it, what is the voltage it will produce at it's max RPM?

- It means that the motor will run on voltage in the range of 208 to 230 volts. It also means that by changing some internal connections under the cover plate, the motor will run on 460 volts instead. Chances are it is an induction run motor without any electrical access to the rotor. As such it will not produce a voltage like an alternator or generator would. Don

- Q:I have an auger that is triggered every 5 seconds for 4 seconds. It spins at 1 rpm. brushless 120 VAC at .5 amp. It can handle about 100 inch pounds of torque. I don't have the ability to change the programming on the motherboard. That would be too easy. lolI want to decrease the rpm in half when I want to without burning up the coils of the motor in the mean time. Could I put a dimmer switch in series with the motor until it puts out 60VAC? I just figured it might get stuck trying to push the load and burn up. It is an expensive little motor to experiment on.Any ideas is appreciated

- Could I put a dimmer switch in series with the motor until it puts out 60VAC? it depends on the exact type of motor. universal or ac/dc motors can be speed controlled, but synchronous motors spin at a rate determined by the supply FREQUENCY so changing the voltage would do no good. Could I put a dimmer switch in series with the motor? no, dimmer switches produce spikes which would do your motor lots of no good, and produce catastrophic interference. And since its an inductive load you would also blow the dimmer.

- Q:It's a 1kW single phase AC pump motor with a 100v supply. This is for a theory question btw. :)

- Depending on what type of motor you have, you can either adjust the amplitude of the AC sine wave or adjust the frequency of the AC sine wave.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords