Siemens High Low Voltage Motor 1PQ Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q:The difference between DC motor and AC motor

- Master formulas n1=60f/P, S= (N1-N), /n1, n= (1-S), 60f/P, and understand their meaning (very important), and be able to flexibly use these formulas for calculations. Also remember: the slip rate of the motor at normal load is approximately SN, 0.01-0.06. The examples in the book should be emphasized.

- Q:how do you calculate the start up current on a 3 phase ac motor?

- i don't know how you would calculate it but the NEC has tables in article 430 that give standard values for different types of motors. perhaps that could help you.

- Q:Provide the difference between basic working and mechanical differences of these both types.And if you can then please also provide good online resources for diagram and mechanism. Thanks

- DC motors have brushes, and AC motors do not.

- Q:fan motor on our ac central unit went out we replaced it but now it wont throw cold air and seems as it wants to cut of or pick up speed .what could it be..

- Either your replacement fain is broken, you replaced it with the wrong fan or you hooked it up wrong.

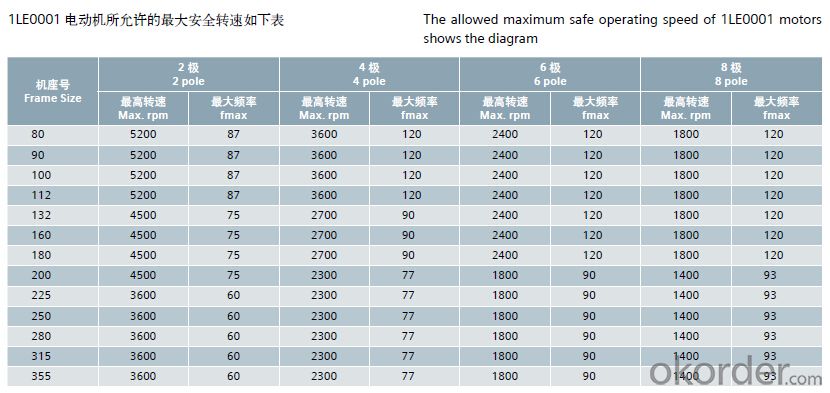

- Q:What is the maximum speed of a three-phase AC motor?

- This motor is divided into pole number, 2 pole motor synchronous speed 3000RPM; 4 pole motor synchronous speed 1500RPM; go down and so on

- Q:a motor that runs on ac and dc?

- Mostly, if they have a lot of power in a small package (especially for rotary speed), but are used only sporadically. They often are a bit noisy. If they have a speed control, then they could be universal.

- Q:AC or DC motors for rolling gate motors?

- Roll gate, also known as "rolling door", is a lot of joint activities of the doors and pieces connected together, in a fixed slide, with the center of the scroll above the center of the rotating door up and down.Roll gate (gate) is suitable for commercial appearance, garage, shopping malls, hospitals, factories and mines, enterprises and other public places or houses.

- Q:I am working on building an automatic cat food feeder out of an alarm clock. When the alarm goes off it triggers a geared motor with a pulley system to pull the lid off a container until a kill switch is struck. I would like to know how to wire the motor to go in the reverse direction after the power is cut, any ideas?Thanks in Advance!

- I believe it is an AC motor not DC. You have both a running winding and a starting winding. If you remove the capacitor from the start winding and put it on the running winding the motor might be able to run backwards.

- Q:Their advantages,disadvantages comparison table?

- V/f control is simply the control of the voltage and frequency applied to an AC motor such that the relationship between voltage and frequency is that the ratio of voltage to frequency is a constant. V/f control is often enhanced by adding “boost,” increasing the V/f ratio at the low end of the frequency range. V/f control would not be considered to be torque control although some protective torque limiting method is often included. Control methods that emulate the armature current regulation control strategy of a DC motor are called flux vector control, field orientation control, or direct torque control. These control strategies mathematically model the motor and estimate its performance by measuring the motor current and the instantaneous vector relationship between the applied voltage and the current. A motor shaft speed and position sensor may be used to determine the instantaneous rotor speed and position. Vector control systems are often called “sensorless vector” when a shaft speed and position sensor is not used. Vector control can provide torque control that allows a torque reference to be set and the delivered torque to be held at the set value with the motor being determined by the torque delivered and the characteristics of the load as long as the drive is within rated limits. The details of the control implementation are generally not fully disclosed by the manufacturers. Since drive performance is affected by the characteristics of the load, manufacturers do not generally provide specific performance information. However, there is a lot of application information available form drive manufacturers. Detailed technical papers are published by the IEEE, but it not always possible to determine which products, if any, implement techniques discussed in IEEE papers.

- Q:again after it sits 3 to 4 hours. What could be causing this?

- Motor Windings are Shot, Replace the Motor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens High Low Voltage Motor 1PQ Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords