Horizontal Maching Center Model HMC630/800 with Siemens/Fanuc/Mitsubishi System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

The horizontal machining center has inverted T structure, high spindle speed, strong rigidity and large torque. This series of machine tools has

perfect performance, stable accuracy, and reciprocating exchange of worktables. It is suitable for processing various types of box parts and two-

dimensional and three-dimensional surfaces. It is the key equipment for processing box parts in machinery, automobile, ship, textile machinery,

printing machinery, agricultural machinery and other industries.

System option:Siemens / Mitsubishi / Fanuc

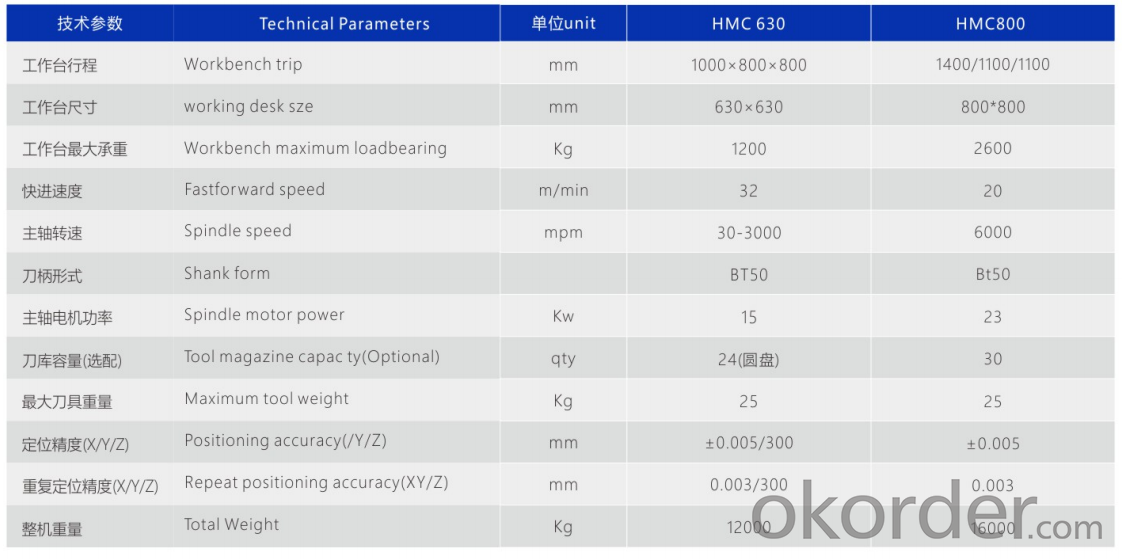

Technical Parameter

Package

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q:What is the difference between CNC lathes and CNC machining centers?

- CNC machine tools, the word is too strong, CNC lathes, CNC milling machines, all CNC can be called CNC machine tools.

- Q:The difference between the heart and the milling machine, I feel like almost! Is not the diameter of the processing machine to be smaller?

- Turning and milling machining center is the turret drive tool movement, the spindle and the workpiece does not move or just rotate.

- Q:Machining center with an end mill milling side of the surface when the collapse is caused by what causes.

- Machining center with the end mill milling side of the surface should be a shock pattern, the main may be too long tool clamping length, or processing margin is too large, or the accuracy of the tool or spindle, when using the end mill Note the following:

- Q:What is the meaning of CNC machining center?

- CNC machining center is a tool with a knife and can automatically replace the tool, the workpiece can be a certain range of a variety of processing operations CNC machine tools.

- Q:Machining center milling depth of 10 mm for planar programming

- Fagordnc software. If you want a computer to communicate with multiple CNC machines at the same time, use http://www.multi-dnc /trial/m-disk.exe.

- Q:Japan vertical processing center Makino, Sen fine, Mazak, brother ....... Which brand of the best? Which is the most expensive price? Comparison of the various brands!

- Now a lot of domestic processing centers have embarked on the machine tool market, the processing effect is no less than foreign processing center, with its high price to buy foreign processing center is better to focus on domestic processing center.

- Q:What is a few axes? Like the XYZ three-axis machining center?

- CNC lathes, turning centers, is a high-precision, high-efficiency automated machine tools.

- Q:What is the machining center? The

- 4, the processing of high precision, stable and reliable processing quality, numerical control device pulse equivalent is generally 0.001mm, high-precision CNC system up to 0.1μm, in addition, CNC machining also avoid the operator's operational errors;

- Q:Is there a need for a tooling center?

- However, due to the current productivity of our country as well as the neglect of human life and health, resulting in most of the processing center did not use the knife or not equipped with knife.

- Q:Processing area of the processing center

- complex surface class parts complex surface can generally use the ball head cutter for coordinate processing, processing accuracy is higher, but the efficiency is low. If the workpiece exists in the processing of interference area or processing dead zone, we must consider the use of four coordinates or five coordinate linkage of the machine. Such as aircraft, car shape, impeller, propeller, all kinds of molding die.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Horizontal Maching Center Model HMC630/800 with Siemens/Fanuc/Mitsubishi System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products