Bar Rod Wire Mill Rolls Spheroidal Graphite Iron Rolls Bainitic Ductile Iron Rolls HSS Rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bar Rod Wire Rolls For Metal Rolling Mills

The Role of Bar, Rod and Wire Rolls in Steel Manufacturing

Bar, rod, and wire mill rolls play a crucial role in the steel manufacturing process, specifically in the production of bars, rods, and wire products. These rolls are an essential component of rolling mills designed to shape and reduce the cross-sectional area of steel billets or ingots into long, slender products like bars, rods, and wires.

Quality Matters: The quality of Bar & Rod Mill Rolls is paramount to achieving the desired product characteristics. These rolls are engineered from materials known for their exceptional hardness and wear resistance, ensuring they withstand the demanding rolling process.

Wide Applications: The products emerging from milling mills, namely bars and wires, find diverse applications across industries. They serve as vital components in construction for concrete reinforcement, in manufacturing for producing various fasteners such as bolts, nails, and screws, and in the automotive sector for crafting components like springs and spokes.

Classification

Nodular Cast Iron Mill Rolls

Bainitic Nodular Iron Mill Rolls

High-Speed-Steel, Semi High-Speed-Steel Mill Rolls

Improved Semi-High-Speed Steel Mill Rolls

As a professional supplier of mill rolls in China, we offer wire & rod rolls crafted the above four distinct materials. This diversity enables us to cater to a wide spectrum of customer needs and budgets, ensuring optimal performance and value for each application.

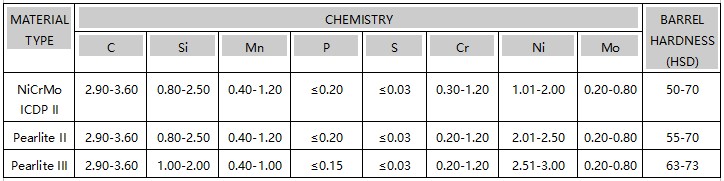

1. Nodular Cast Iron Mill Rolls (Ductile Iron Mill Rolls, Spheroidal Graphite Iron Mill Rolls)

Classification

NiCrMo ICDP II

Pearlite II

Pearlite III

Chemistry and Surface Hardness

Metallographic Structure

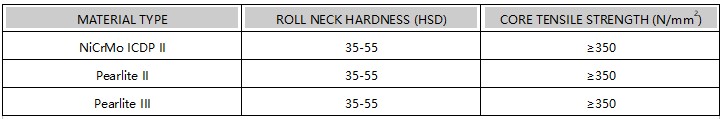

Mechanical Properties

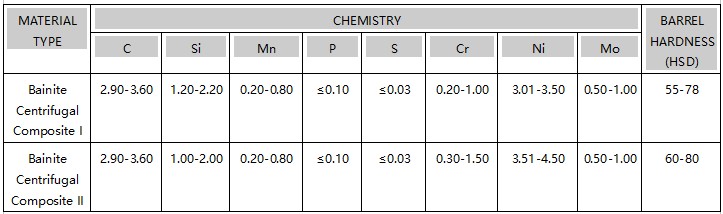

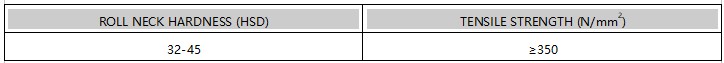

2. Bainite Nodular Cast Iron Mill Rolls (Bainitic Ductile Iron Mill Rolls)

Classification

Bainite Nodular Cast Iron Composite Centrifugal I

Bainite Nodular Cast Iron Composite Centrifugal II

Chemistry and Surface Hardness

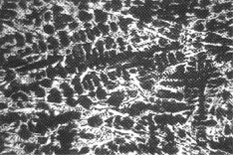

Metallographic Structure

Mechanical Properties

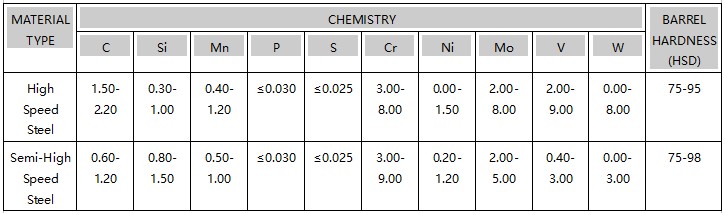

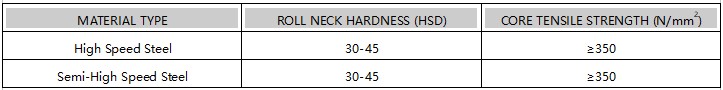

3. HSS, Semi-HSS Mill Rolls

Classification

High-Speed-Steel Mill Rolls

Semi High-Speed-Steel Mill Rolls

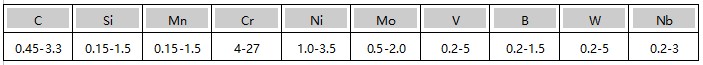

Chemistry and Surface Hardness

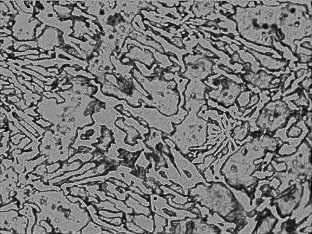

Metallographic Structure

Mechanical Properties

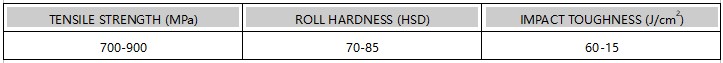

4. Improved Semi-High-Speed Steel Mill Rolls

Performance Index

Chemistry

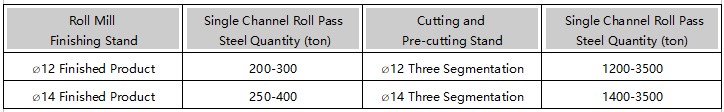

Roll Pass Steel Amount Reference

Metallographic Structure

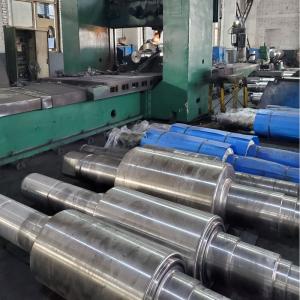

Milling Roll Production Equipment

At CNBM International Corporation, we take pride in delivering top-quality milling rolls to meet the diverse needs of our clients. Our commitment to excellence begins with the state-of-the-art equipment that our factory uses in our manufacturing process. Our comprehensive range of equipment ensures precision, durability, and reliability in every milling roll we produce.

Casting Equipment

10-ton Centrifuge

Centrifugal Roll Pouring Site

10-ton Medium-Frequency Furnace

Integral Rolling Roll Casting Site

Heat Treatment Equipment

High-Temperature Resistance Furnaces

High-Temperature Resistance Furnace Output

Dual-Frequency Rolling Roll Quenching Machine

Machining Equipment

6m Gantry Milling Machine

CNC Machine Tool

Our Workshop

Horizontal Lathes

Grinding Machine

Roll End CNC Letter-Engraving Machine

Testing Equipment

Metallographic Microscope

Dimensional Inspection and Measurement

Spectrometer Testing

On-Site Roll Metallography Testing

Ultrasonic Flaw Detector

Hardness Testing

Actual Mill Roll Product Photos

- Q:How can make powder metallurgy machinery fittings have hardness, toughness?

- The methods are as follows:Increasing the density of powder metallurgy parts.

- Q:What kind of high temperature anticorrosive coating is used for metallurgical high temperature parts?

- The alternating coating of hot and cold can not crack and fall off. The coating is dense, acid resistant and alkali resistant, and can withstand high temperature 1300 DEG C. FDA certification, non-toxic environmental protection.

- Q:Why does the aspect ratio of powder metallurgy machine parts need to be controlled?

- This is the material, process, mold, equipment restrictions,When the material is pressed in the height direction, the density is too high, but the diameter is too high. The density gradient is too large and the strength of the blank is too low to form.

- Q:Process flow of powder metallurgy parts plating

- The formation of powder metallurgy electroplating process is mainly because the powder metallurgy parts is the use of metal powder pressing and sintering, thus containing oil and porous, which requires the electroplating process in powder metallurgy, electroplating processing, all kinds of solution into the pores of the coating has great impact on the quality of.

- Q:How to strengthen the shock resistance of powder metallurgy metal parts?

- The finer the crystal powder, the better the stress after sintering.

- Q:What are the types of powder metallurgy machinery parts?

- Powder metallurgy parts can not be subdivided into different types, because different metal, nonmetal and other additives are added in the matrix material to achieve different effects, which need to be decided according to different performance requirements.

- Q:What kind of imported metallurgical machinery parts do steel mills need to rely on?

- Domestic is not impossible and foreign than, the key is that performance is not as good as abroad, especially in our domestic metallurgical enterprises equipment, production processes, are lagging behind than in other countries.

- Q:What is the cost of the powder metallurgy machine parts?

- Cost level and process, production technology, operation methods, the use of equipment, labor costs are greatly related.

- Q:Why are powder metallurgy parts generally small?

- Most of the forming technologies of powder metallurgy products are pressing forming and injection molding, which limits the size and shape of parts.

- Q:What is the manufacture of powder metallurgy machinery parts?

- Powder metallurgy is similar to the production of ceramics, all belong to powder sintering technology. Therefore, a series of powder metallurgy new technology can also be used for the preparation of ceramic materials. Because of the advantages of powder metallurgy technology, it has become the key to solve the problem of new materials and plays an important role in the development of new materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bar Rod Wire Mill Rolls Spheroidal Graphite Iron Rolls Bainitic Ductile Iron Rolls HSS Rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches