Professional Aluminum Sheet Manufacturer in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

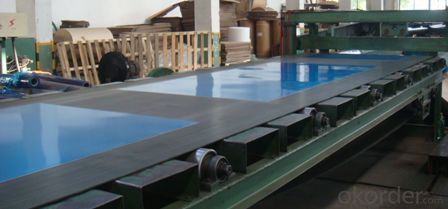

aluminum sheet manufacturer in China

1.High quality aluminum sheet/coil

2.Reasonable price

3.Prompt delivery

4.Wearability

Professional Aluminum Sheet Manufacturer in China

1.High quality pure aluminum sheet/coil

2.Reasonable price

3.Prompt delivery

4.wearability

Description of aluminum sheet

Description of aluminum sheet | |

Alloy No.: | 1100 1050 1060 1070 1230 3003 3004 3005 3104 3105 5005 5052 5754 5083 |

Temper: | O -- H112 |

Thickness: | 0.08-150mm |

Width: | 150-2000m |

Surface Quality: | Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Discoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use. |

Place of Origin: | Henan,China (Mainland). |

Packing: | Wooden pallets with paper intereaved or customized packing ways are welcomed |

Application: | construction , decoration,packaging, printing. |

Loading port: | Qingdao(any port in China). |

Remark: | Specific requirement of alloy grade,temper or specification can be discussed at your request. |

Photos

- Q:Ok.here's my pumpkin roll recipe.3 eggs, 1c sugar, 2/3 c pumpkin, 1t lemon juice, 3/4 c flour, 1t ginger, 1t baking powder, 2 t cinnamon, 1/2t nutmeg, 1/2t salt.Beat eggs on high for 5 minutesGradually add other ingredients and mix wellSpread into well greased 15x10x1 panTop with chopped nuts and bake 15 min 375Turn out on flour sack towel, liberally sprinkled with powered sugarRoll up with towelCoolUnroll and spread with cream cheese mixRoll and wrap in foilSo, how do I tweek this to be chocolate?!?! Thanks!!!

- it was fat, put bbq towards the end of your cooking of the chicken, some put bbq sauce for day last few minutes

- Q:For one, I'll be dead before the affects appearI say, make the govt put restrictions on how things are packagedPackage stuff in biodegradable materialWhy do I have to work for the way someone packaged something?! F that!

- An American discards an average of one ton of trash per person per year, if that seems ok, it is two to three times as much as a typical West EuropeanCan you stand back and be beaten like that? Consider this; Americans junk enough aluminum cans to replace all the country's commercial aircraft.every 3 monthsThe ecological footprint of the average Canadian is one third less than an AmericanI think Americans should start showing the world what you're made ofYou have a history of doing things bigger and betterStart winning the re-cycling race not dropping out at the first hurdle! On a more serious note though, all I have to do is put anything that can be re-cycled (glass, paper, tins, plastic) into a re-cycling trash bag put it out once a week and off it goes to be re-cycled (incl bag)This would change things dramatically if the U.Shad the same systemSo I say make your government restrict packaging and improve re-cycling or you just might find something nasty happening in your life time.

- Q:What is the best way to ship cookies without them getting stale and broken all up?

- good one ( pesto) 1 1/2 ounces Toasted pine nuts 3 each Garlic cloves, minced 1/2 ounce Salt 10 1/2 fluid ounces Olive oil 4 ounces Basil leaves, washed and dried well 2 ounces Parmesan cheese, gratedDIRECTIONS: 1.Place nuts, garlic, half of the salt, and half of the olive oil into a blender or food processor fitted with the blade attachmentBlend to a paste, about 1 minute2.Begin adding basil leaves gradually and blend on and off to incorporate basil into the emulsionAdd the additional oil gradually until the paste is thoroughly combined3.Adjust the seasoning with salt as neededAdd the Parmesan cheese and blend just before servingPesto should be stored under refrigeration with a layer of oil across the surface (hummas) INGREDIENTS: 2 cloves garlic, peeled and crushed 30 ml olive oil 1 (15 ounce) can garbanzo beans, drained, liquid reserved 9 g sesame seeds salt and pepper to taste DIRECTIONS: 1In a medium saucepan over medium heat, cook and stir the garlic in olive oil for approximately 3 minutes, until tender2Place garbanzo beans in a blender or food processor with approximately 1 teaspoon reserved liquidProcess until smoothMix in the garlic, sesame seeds, salt and pepperBlend to desired consistency, increasing the amount of reserved garbanzo bean liquid as desiredChill in the refrigerator until servingthanks chef Richard

- Q:Is aluminum foil pure aluminum?

- No, it is aluminum alloy. it is a kind of composite material. Aluminum foil is a kind of thermoprinting material made by calendaring aluminum into sheet. Since its thermoprinting effect is similar to that of silver foil, it is also called fake silver foil. As aluminum is soft and ductile with silvery luster, aluminum foil sheet can be made by mounting calendered aluminum sheet on the offset paper with sodium silicate, which can be used to print. But the color of aluminum foil will gradually become dark as it is easy to be oxidized and it fade due to friction and touching, so it is not applicable to the thermoprint of book covers for permanent preservation. No, because packaging bags made by aluminum, rubber and plastic containPE POV POF which can’t be resolved by soil.

- Q:question about a litter box?

- I'm sure if she needs to go, she'll use itSome kitty's are shy, she may not want to go with someone watching herThe tray should work just fine for one nightPlus, if it has new litter in it, she may not know until she has to go, that that's her litter box for the time beingMy cat once tried (and succeeded without me watching) to go in my turtle's tank when it was on the floorCats will go anywhere they are able to dig and bury theirDon't worry, i'm sure the kitty tray will work:) best wishes ~SEW

- Q:I know that phosphorus is near the noble gas to complete it's octect but why is aluminum 3+? I know aluminum is under the group 3A so it has 3 valence electrons BUT WHYWhy can't aluminum be 5- or phosphorus could be 5+?

- Because aluminum is a metalPhosphorus is a nonmetalMetals have positive valences.

- Q:An aluminum wire of diameter 2.6 mm carries a current of 11 AHow long on average does it take an electron to move 11 m along the wire? Assume 3.5 conduction electrons per aluminum atomThe mass density of aluminum is 2.7 g/cm3 and its atomic mass is 27 g/mol.

- add charcoal, two squirts of fluidI would just light a piece of paper and throw it in there so you dont burn your arm hairs offyes aluminum foil is safe(but if you want to e technical, its not healthy for youperiod.) and yes, you can season your food any place you want, I would do it beforeand yes if the park has a grill, it should be functional to throw your food onYou shouldn't have to bring extra grill parts in less its in the ghetto.

- Q:I have aluminum wheels that are chrome plated and all of the chrome is bubbling up and flaking offI've tried sandblasting them with no luckNow I've just been using a paint scraper and a pair of pliers to pull it offIs there an easier way? This is so tedious and I keep getting cut up from the chrome.

- OUCH! I hope you didnt pay for those rims! IF possible, I suggest you take em to a shopIt shouldnt cost more than a couple of dollars and they will leave em clean or re-chrome emDont stress your self either.it will all eventually fall off on its own! Hope all works out!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional Aluminum Sheet Manufacturer in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords