Aluminium Foil Paper For Cigaratte Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Packaging Details: | Standard export packing or following customer's demand |

| Delivery Detail: | Within 10-20days or according to the order quantity |

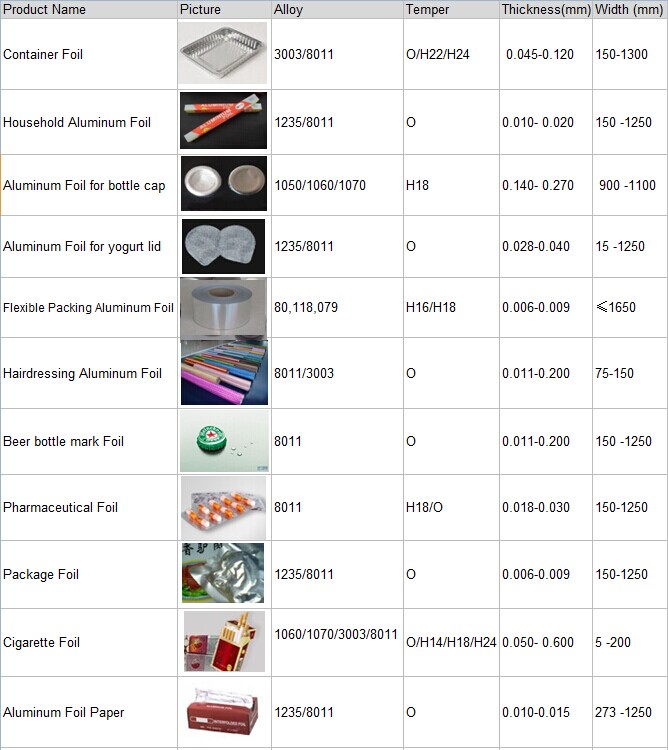

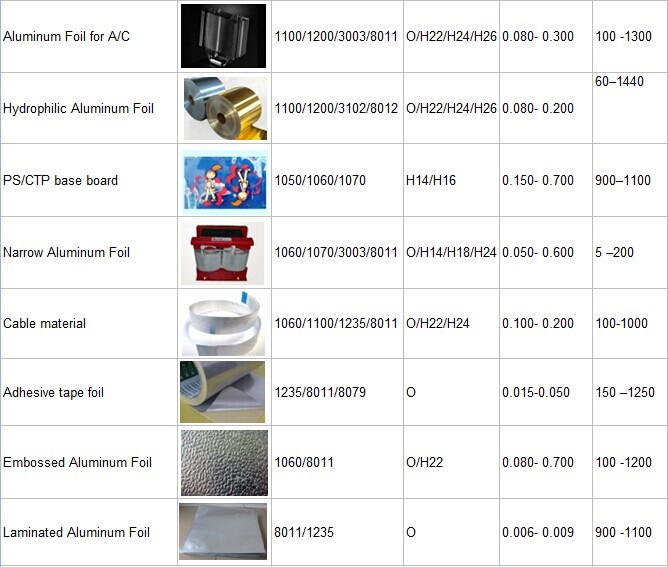

Specifications

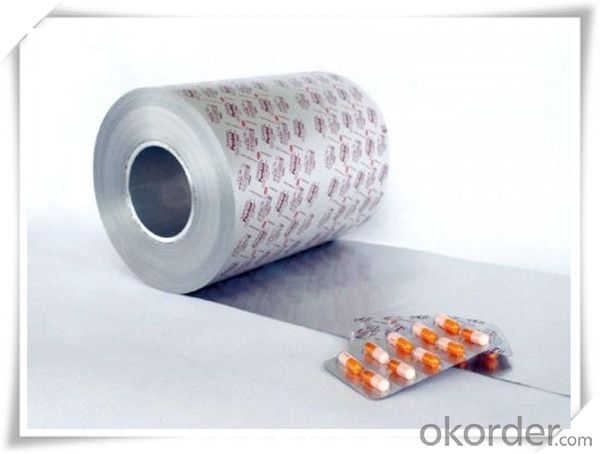

1.Grade: 1235,8011,8079

2.Thickness:0.015mm-0.05mm

3.Width: 150mm-1250mm

4.Temper: O

5. Standard: JIS, AISI, ASTM, GB, DIN, EN

6.Certification: ISO

7.Thickness tolerance:+/-2%

8.Width tolerance: +/-3%

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn |

| 1235 | Si+Fe:0.65 | 0.05 | 0.05 | 0.05 | - | - | 0.1 | |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | - | 0.1 |

Applications

Aluminum Foil Adhesive Tape is specially used for the sealing of pipelines connectors in refrigeration equipment and heating equipment etc; adhesion and fixation of pipelines in various refrigeration equipments

1. For coupling and sealing pipe joints in ventilation, air condition and refrigeration system, Joining and sealing flexible air duct seams and connections.

2. For coupling and sealing boards, panels, blocks or pipe joints in implementing construction-and-assembling operations.

3. May also be used for other industrial uses requiring a tape with these characteristics and benefits .

We also produce the following categories of products

Our company utilizes a 1650 high-speed universal aluminum foil mill production line of high level of automation, an elite imported thickness tester, and an automatized control system. Together with the special corollary equipment, such as the automatically controlled winding machine, CNC grinding machine, BMJ's production technique, capacity, and quality of thin aluminum foil products lead domestic markets.

Photos

- Q:I am only one person and would need to toss it on top of my car to go fishin'.

- i have a 10' richline that weighs 75 lbs emptyim not sure about current manufacturersbut there seem to be two grades of aluminum boatone being much heavier than the otheri found mine in an old mans back yardim not sure anyone produces the the lighter versions anymore.

- Q:A box of aluminum foil cost $7.78The box contained 500 sheets of 12quot;X10 3/4quot; foilDetermine the cost per square inch of the aluminum foilReport the answer in dollars/in^2

- need more info like whats on there now and what is the tach/rpms at and how fast r u going

- Q:Assume everyone in the US consumes one aluminum can every TWO DAYSIf there are 270 million Americans, how many TONS of aluminum are needed a YEAR if ONE CAN weighs ONE OUNCE

- Fiber helps in digestion and cleans your stomachIt doesn't directly make you poop but since it helps you in digestion the manifestion is having a regular poopWheat and Oatmeal is a good source of fiber.

- Q:what are the things you are doing to stop the destruction of our environment?

- I have recycled all my lifeI keep my car in tip-top shape to make sure all systems work efficientlyI buy recylcled products as much as possibleReuse plastic kitchen bags and aluminum foil when feasibleTake my own grocery bags to the storeWhenever possible, I don't buy things wrapped in plasticWon't buy soft drinks in those 6-pack plastic ring containersI buy only organic, pesticide free fruits and vegetablesI don't buy any produce from California at all unless it is certified organicThey use WAY too much spray - and spread it by plane in the valleysI have been doing this for so long it is just natural.

- Q:Question 1)The space shuttle's solid rocket boosters use ammonium perchlorate and aluminum to create an explosive reactionThe unbalanced reaction can be seen belowNH4ClO4 (s) + Al (s) Al2O3 (g) + HCl (g) + N2 (g) + H2O (g) Which of the following statements correctly describes this reaction? Chlorine is being oxidizedAluminum is gaining electronsNitrogen is being reducedAluminum is a reducing agent.Question 2) Which of the following requires an oxidizing agent? Al -gt; Al3+ 2 O -gt; O2 Cl2 -gt; 2 Cl- Ag+-gt; AgQuestion 3) Which of the following reactions is not an example of an oxidation-reduction reaction? 3Br2 + 2Ga -gt; 2GaBr3 H2S + Cl2 -gt; 2HCl + S 2PbS + 3O2 -gt; 2PbO + 2SO2 K2Cr2O7 + KOH -gt; 2 K2CrO4 + H2OQuestion 4) Which of the following represents the salt produced when the base magnesium hydroxide, Mg(OH) 2, reacts with strong hydrochloric acid (HCl)? H2O MgCl MgCl2 H2O and MgCl2Please help i will greatly appreciate it

- use her stuff irritate her.i dont have a sister actually so i think i cant give good advice.sorry

- Q:I am going to be going for 4 day camping with about 30 girls and we are going to a campsite right on top of the kern riverI need some good pranks, 2 foil dinner recipes, one with shrimp one without, and some secret sister ideas, thanks!

- Get tips from weight loss community

- Q:I think this is silly but im just curious my little sister is a big theif nd were trying to get her to stop and she got in trouble where cops were involved and a officer asked her quot;how do you do itquot; she like quot;line the inside of your bag with foil and put the stuff you jack inside and the censor wont go offquot; is this true???And if it is please explain this sounds so dumb i mean if it was really as simple as that wouldnt alot more people do it theft would be a way bigger problem.??

- Foil will block RFID (radio frequency identifier) signals which could make this possible.

- Q:I have a silver charm and it looks black because it's oldHow can I restore it to it's original silver color?

- I collect silver and this is the method I useIts simple, and it is done safely with common household ingredientsTake a microwave safe bowl and fill it 1/2 full with waterMicrowave the water until it is about as hot as if you were making coffee or teaAdd 1 teaspoon of table salt, and 1 teaspoon of baking sodaStir well, until both are dissolvedNext take a small piece of aluminum foil and put it in the water/salt/baking soda liquidIt will probably float, but then put your charm on the aluminum so that it sinks and the charm is touching the foil and both are under waterLet this sit, a electro-chemical reaction will peel the tarnish offAfter about 30 seconds, pull the charm out and wipe it with a q tip That should bring all the shine back! And this method is gentle on the silverGood luck!

- Q:If the oven's set on Broil, can we put paper in it (the ones that they give you to put greasy food on at restaurants).

- Wax paper should never be used unless it is at the bottom of a cake pan and covered with cake batterIn a similar manner you can use paper cup cake holdersParchment paper is commonly used on the bottom of cookies sheets to make clean up easierThe box we have in the kitchen says to not put in an oven over 420 degs FIt also says to not expose it to an open flameI would never put any kind of paper in an oven if it is set on broilThere is a good chance you will set the paper on fire and at least end up with a mess or worseOnly use aluminum foil in conjunction with a broiler.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Foil Paper For Cigaratte Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords