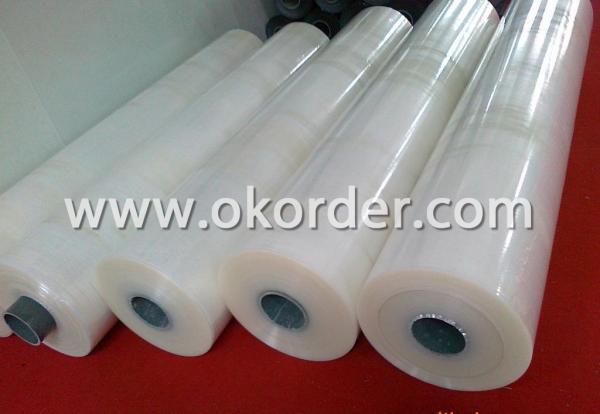

High Quality Transparent Color PE Protective Film S60-50T

- Loading Port:

- China Main Port

- Payment Terms:

- TT Or LC

- Min Order Qty:

- 10000 Square Meters m²

- Supply Capability:

- 10000 Square Meter Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application: Mirror finish stainless steel need sophisticated protection. Usually 2layers white color 30micron PE protective film are used. But you can also use 1layer transparent PE protective film which is thicker, such as 50micron. So that the steel is well protected from dirt and scratch during production, transportation and installation.

2. White color and transparent color are popular for mirror finish stainless steel surface protection. Transparent blue color, black & white color, red color and so on available as per customers' requirements.

3. The choice of surface protective film depends on the surface: material and roughness. Tell us what surface you want to protect and we will recommend proper film to you.

Technical Data of High Quality Transparent Color PE Protective Film S60-50TItem Number: S60-50T

Carrier: PE (polyethylene) film

Thickness: 50micron (0.05mm)

Peel Adhesion: 60g/25mm

Adhesive: solvent acrylic

Color: transparent

Temperature Resistance: 60C 48hours no residue

Elongation: ≥250%

Inner Diameter: 3" (76mm)

Length: within 3000meter

Widh: within 1.5meter

Recommended jumbo roll size: 1.0m x 1000m

Packing of High Quality Transparent Color PE Protective Film S60-50T

Wrapped with kraft paper or carton.

Remarks of High Quality Transparent Color PE Protective Film S60-50T

A. The data above are typical results and subject to change without notice.

B. Tolerance: 5%

C. The products should be stored at room temperature and be kept away wet and/or heat source.

D. It is essential, the surface of film must be clean, dry, and free of grease and oil.

E. The users should take test and do trial-application on the above product before coming into application so as to witness and ensure suitability for their special purpose and technique

- Q:I just bought a refrigerator. What to do before I use it? Do I need to tear off the protective film?

- Don't do that because the film can keep your refrigerator well sealed.

- Q:What is PVC material protective film?

- PVC protective film is based on its film substrate to distinguish, because PVC film as substrate, so called PVC protective film, PVC light transmittance is relatively high, belongs to non crystalline chemical plastics, therefore, can also be made transparent. The main purpose is through sticking protective film on the object to package goods not to scratch the surface in transportation and processing, such as stainless steel plate stamping with protective film without leaving traces.

- Q:Just buy a table tennis racket, after the film is very sticky, how to do?

- Tip: to judge a good or bad rubber, one of which is sticky, can table tennis stick up, upside down for a few seconds, is not good, it is good rubber!

- Q:Does protective film for laptop keyboard affect heat dissipation?

- I suggest you'd better not use keyboard protective film because it will impede the heat dissipation of the computer. If you don't like your keyboard being dirty, you can use blush to clean it (usually included in laptop cleaning kit). And keeping it clean at other times.

- Q:How many labels are there on tempered film? I mean the things that should be torn off when using the film.

- There's two labels (label No.1 and No.2). We should peel the layer of film marked by label No.1 at first when we coat the screen with the film. Thank you. If you have other questions, you can ask me again.

- Q:What are the unique properties of PET protective film?

- Property 1: Highly adhesive, fairly sticky and anti-solvent. When used in the normal temperature environment, the sidelines of the film stay straight and no glue remains. Use: Apply to decoration and ordinary industrial sheltering. Property 2: Excellent whether resistance. Apply to use at temperature below about 150℃. No residual glue. And the boundary of color separetion is clear. Use: Apply to car color covering and industrial machinery painting. Property 3: Special PET material with high tensile strength as well as acid and alkali-resistance. No permeation and no residual glue. Use: Apply to spray paint at high temperature. The film is made from sprcific materials, making it resistant to high temperature and environmental friendly. Once coated, the film will not fall off. And no glue will remain. It's the best choice for the protection of coatings like LCD, ITO, PMMA and PC. The Hualibao company is working on protective films. You can go there to learn more about PET protective films. It is suitable for automobile color cover.

- Q:What kind of material is acrylic protective film made from?

- Usually, the protective film used on acrylic panels and sheets is made from PE materials.

- Q:What is PVC protective film?

- 1. It has the property of highlight and high reflective which is commonly called the mirror effect. 2. It has resistance to acids and alkali as well as corrosion. And no residual glue remains when removing the film. Use: It can be widely used on the protection of stainless steel sheets as well as aluminium products and industrial products during processing. The scotch tapes hanging on the doors of many restaurants are also made from PVC materials which are generally called PVC films. We have many nice films of this type . And we assure you they are all of good quality and reasonable price.

- Q:What are the advantages of PET protection films compared with other protective films?

- Because there are many kinds of protective film, I give two examples of PET protection film and PE protection filmThe difference between PET protective film and PE protective filmPET protective film, also called film high temperature resistant polyester film. It has excellent physical properties and chemical properties and dimensional stability, transparency, Recyclable, can be widely used in magnetic recording, photosensitive materials, electronics, electrical insulation, industrial film, packaging, decoration and other fields. Can be produced into mobile phone LCD protective film, LCD TV protective film, mobile phone buttons, etc..

1. Manufacturer Overview |

|

|---|---|

| Location | Zhongshan, China |

| Year Established | 2004 |

| Annual Output Value | US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen Port |

| Export Percentage | 10% |

| No.of Employees in Trade Department | 50-100 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | protective film |

| Product Price Range | High; Average |

Send your message to us

High Quality Transparent Color PE Protective Film S60-50T

- Loading Port:

- China Main Port

- Payment Terms:

- TT Or LC

- Min Order Qty:

- 10000 Square Meters m²

- Supply Capability:

- 10000 Square Meter Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords