Plain Aluminium Coils Used for Producing ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Plain Aluminium Coils Used for Producing ACP

Plain aluminium coils used for producing ACP are good at ductility, heat conductivity, anti-corrosion and moisture resistance.

They are widely used as base coils to produce ACP after being coated. Normal specification is 3003, H16, etc.

2.Main Features of Plain Aluminium Coils Used for Producing ACP

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

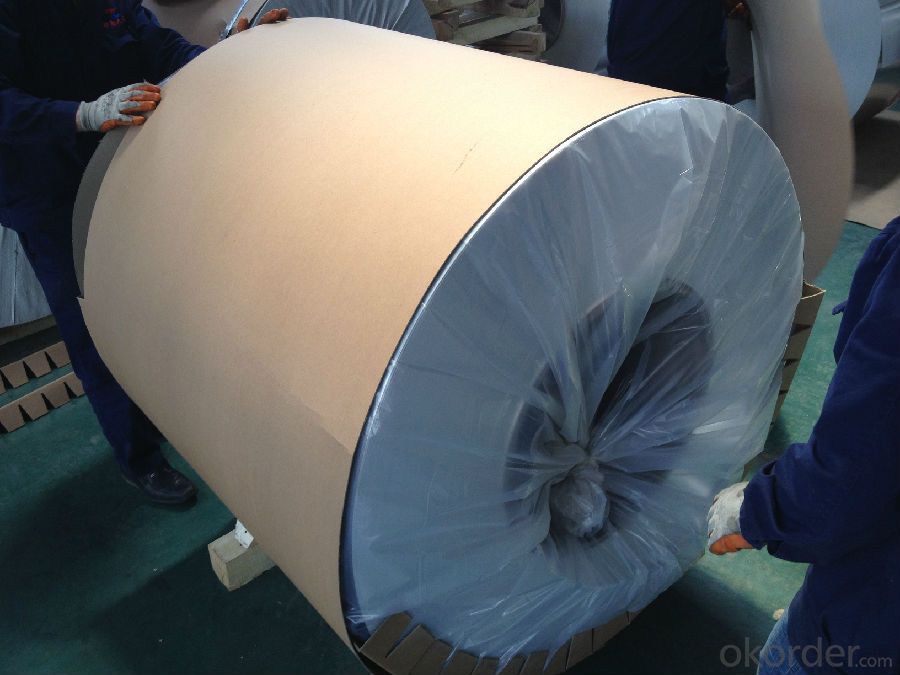

3. Plain Aluminium Coils Used for Producing ACP Images

4.Specification of Plain Aluminium Coils Used for Producing ACP

Alloy: AA3003, AA3105, etc

Temper: H16, H26, etc

Thickness: 0.3-1mm

Width:1000mm- 1500mm

Standard: GB/T3880-2006, ASTM, ISO, EU standard

5.FAQ of Plain Aluminium Coils Used for Producing ACP

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:What does 1060 stand for in 1060 aluminum rolling?

- It means the aluminum content should be above 99.6%.

- Q:Can aluminum coils be used in agricultural applications?

- Yes, aluminum coils can be used in agricultural applications. Aluminum is a versatile and durable material that can withstand various environmental conditions, making it suitable for agricultural equipment such as irrigation systems, greenhouse structures, and ventilation systems. Additionally, aluminum's light weight and corrosion-resistant properties make it an ideal choice for agricultural applications where durability and long-term performance are essential.

- Q:1mm how much is one square meter for aluminum rolls?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.

- Q:How are aluminum coils used in the production of musical instruments?

- Aluminum coils are widely used in the production of musical instruments due to their unique properties and advantages. One of the main uses of aluminum coils is in the manufacturing of guitar pickups. These coils are wound around a magnetic core and serve as the primary component for capturing the vibrations of the guitar strings and converting them into electrical signals. The electromagnetic properties of aluminum make it an excellent material for this purpose as it allows for the precise sensing and amplification of the instrument's sound. In addition to guitar pickups, aluminum coils are also utilized in the production of other instruments such as electric keyboards, synthesizers, and electric violins. These coils are essential for the generation and transmission of sound signals, ensuring high-quality audio output. Aluminum's lightweight nature makes it a preferred choice as it doesn't add unnecessary weight to the instrument, allowing for ease of handling and improved portability. Moreover, aluminum coils are employed in the construction of wind instruments like saxophones and trumpets. They are used to shape the tubing and create the body of these instruments. Aluminum's corrosion resistance properties are particularly valuable in this application, as it helps to maintain the instrument's durability and longevity. Overall, aluminum coils play a vital role in the production of musical instruments by providing a reliable means of capturing, transmitting, and amplifying sound signals. Their unique properties, such as electromagnetic sensitivity and corrosion resistance, make them an ideal choice for ensuring high-performance and longevity in various musical instruments.

- Q:How are aluminum coils processed for specific thicknesses?

- To achieve specific thicknesses, aluminum coils undergo a series of manufacturing steps. The journey begins by casting molten aluminum into large ingots. These ingots are then transformed into thin sheets through the use of a hot rolling mill. To reach the desired thickness, the first step is hot rolling. The aluminum sheet is gradually reduced in thickness as it passes through a sequence of heated rollers. This process is repeated several times, with reheating occurring between each pass. Through hot rolling, the sheet is elongated and made thinner. Following hot rolling, the sheet may undergo cold rolling. This involves passing the previously hot rolled sheet through a set of cold rollers. Cold rolling further decreases the thickness and enhances the surface finish of the aluminum. It also enhances the material's strength and hardness. After this, the sheet is annealed. This entails heating it to a specific temperature and then allowing it to cool gradually. Annealing serves to relieve any internal stresses and enhance the overall ductility of the aluminum. Once the desired thickness is achieved, the aluminum sheet is typically cut into coils using a slitting machine. These coils can then undergo further processing or be utilized in various applications, such as the manufacturing of automotive parts, packaging materials, or building construction. In summary, the process of producing aluminum coils with specific thicknesses involves hot rolling, cold rolling, annealing, and slitting. These steps ensure that the aluminum sheet meets the required thickness specifications and is ready for further use in diverse industries.

- Q:What is the maximum coil weight that can be produced?

- Several factors, including the type of material being coiled, the size and capacity of the coiling equipment, and the strength and durability of the coil itself, determine the maximum weight of a coil that can be produced. Generally, the maximum weight of a coil can vary from a few pounds to several tons. However, it is important to consider that exceeding the recommended maximum weight of a coil can result in safety hazards, equipment damage, and compromise the quality and integrity of the coil. Therefore, it is crucial to refer to the manufacturer's guidelines and specifications to ascertain the maximum weight of a coil that can be safely and effectively produced for a specific application.

- Q:Can aluminum coils be used for outdoor applications?

- Yes, aluminum coils can be used for outdoor applications. Aluminum is a highly versatile and durable material that can withstand various weather conditions and temperatures. It is resistant to corrosion, making it suitable for outdoor environments where moisture and humidity are present. Additionally, aluminum coils are lightweight, which makes them easier to transport and install in outdoor settings. They are commonly used in outdoor applications such as roofing, siding, gutters, and HVAC systems. Overall, aluminum coils are a reliable choice for outdoor applications due to their strength, corrosion resistance, and longevity.

- Q:What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q:what language did Aluminum and Uranium originate from ? Who or what were they named for ?

- The ancient Greeks and Romans used alumen (alum, potassium aluminium sulfate, K2Al6(OH)12(SO4)4) in medicine as an astringent, and as a mordant in dyeing. Alum was exported from ancient Greece and Italy. In 1761 the French chemist Louis-Bernard Guyton de Morveau (1737-1816) proposed the name alumine for the base in alum. Guyton de Morveau was instrumental in setting up a standardised system for chemical nomenclature and often collaborated with Antoine Lavoisier, who in 1787, suggested that alumine was the oxide of a previously undiscovered metal. In 1808, Sir Humphry Davy (1778-1829) did experiments for the decomposition of alumine, silex, zircone, and glucine. He failed to isolate the metals in these, as he reported in his paper for the Royal Society of London on 30 June 1808, but he suggested names for the metals (note) Cf. Silicium, Zirconium, and Beryllium (Glucium) Thus he proposed the name alumium for this still undiscovered metal and later agreed to change it to aluminum. Shortly thereafter the name aluminium was adopted to conform with the -ium ending of most elements. Uranium was named by its discoverer German chemist Martin Klaproth, after the last planet to have been discovered Uranus.

- Q:i need to know if Aluminum absorbs radio waves (just the type that control an RC jet)

- Aluminum reflects radio waves; it does not absorb them.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plain Aluminium Coils Used for Producing ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords