Factory Acoustic Perforated Aluminum Ceiling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

2014 New fireproof aluminum ceiling

Specification:600*600

Material: Aluminum alloy

Certification:ISO,BV, TUV

Factory price

1) Our clip in aluminum ceiling:

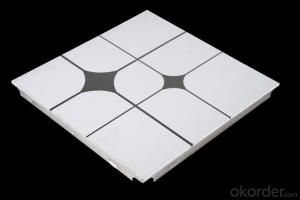

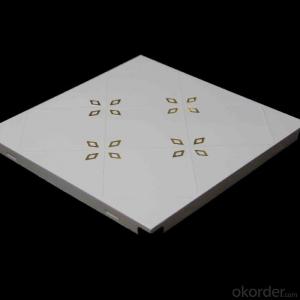

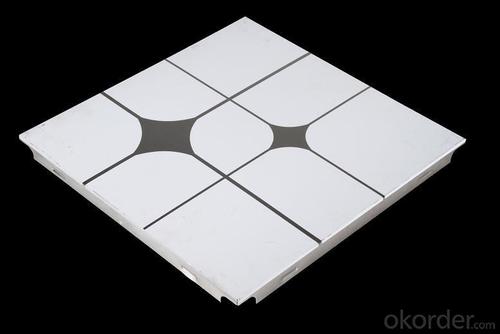

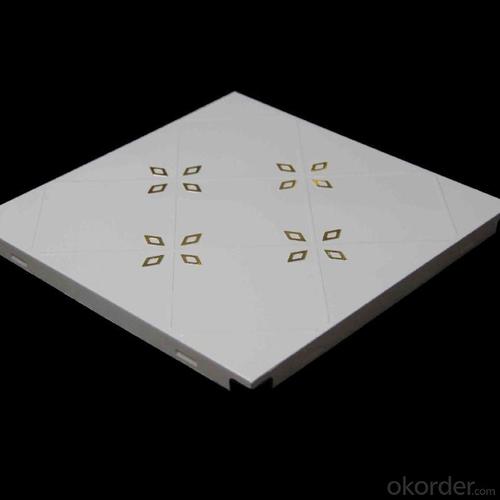

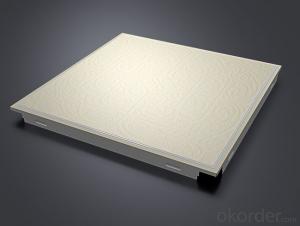

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

2) Specifications:

| Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

| Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

| 600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

| 800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

| 300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

| 600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

| Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

| 575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

| 585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

| 585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

| 595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

| 603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

| Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

| Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

| 75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

| C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

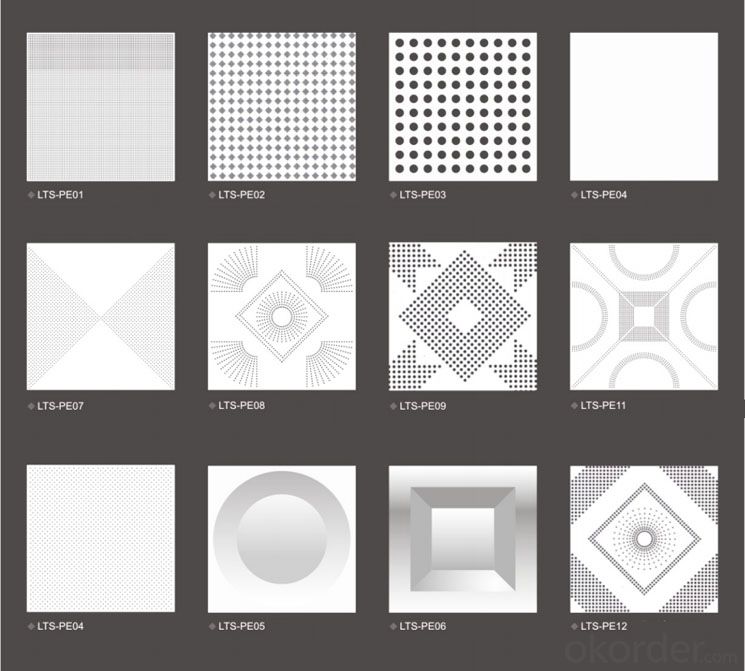

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

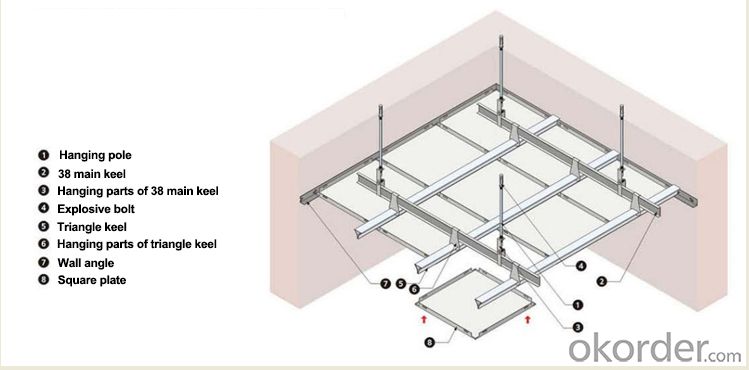

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

- Q:3DMAX in the aluminum slab ceiling how to do real? (In addition to using the map)

- No map, I really did not do. Do not map to do these things, like no PS do the same background. Even if you have the energy, but the computer can not afford ah

- Q:Integrated ceiling aluminum slab plate production process?

- Integrated ceiling aluminum plate production process: Kouban production is a very rigorous process, every link is very strict, so that it can produce qualified aluminum slab products. The first step is the aluminum plate surface treatment, such as film, roller coating, spraying, wood transfer and so on. The second part, aluminum plate scissors. It means that the aluminum roll cut into the required size. Such as 300 * 300 specifications. The third part, press molding. Using different aluminum buckle plate abrasive extrusion. There are two parts: strip and square. Fourth, the packaging. Carton and plastic foam packaging out of the library.

- Q:Aluminum buckle ceiling ceiling area is how to count

- If you calculate the area of a piece of gusset, such as 30 cm long, 30 cm wide aluminum gusset plate, an area of 0.3 m * 0.3 m = 0.09 square meters

- Q:Where is the line to be done

- Aluminum plate closed edge is done on the wall, you can use the expansion screw and glue the way fixed fixed edge, and then install the aluminum plate.

- Q:How to dismantle the aluminum plate

- The general home are 300/300 square aluminum slab board directly to the supermarket to buy the kind can be sucked in the glass or the wall of the vacuum sucker hook, get some vegetable oil wipe the surface of the sucker, attached to the ceiling to the next Pull like, the board will be off, and then how do you want to demolition how to split, square aluminum ceiling is full of triangular keel clip fold fixed,

- Q:Can the aluminum plate be cut and installed?

- 1, the buckle plate can be cut to install, the buckle is stuck in the metal stuck in the above. 2, the direction of cutting is best horizontal, vertical there is not good. 3, aluminum plate is aluminum alloy plate as the base, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum buckle board, the most important There are two types, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab plate mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum buckle Plate has been varied, a variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum plate, home improvement integrated aluminum plate Is the board fancy, life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid Mainly, of which milk is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating life to maximize the ability to achieve To ensure that the interests of owners.

- Q:Buy aluminum plate, need to pay attention to what

- Cabinet, Wei ceiling material is mainly aluminum plate and PVC, plastic steel or a strict PVC, but thicker some, essentially no difference, the aging of plastic things is inevitable, in the health of this humidity, Where the temperature is high or the aluminum plate is better. Decoration teams are generally recommended PVC, the real reason is the installation of trouble with aluminum gusset plate, they said that all the shortcomings of aluminum plate, often fabricated out. PVC ceiling is made of PVC, the material is very light, poor oxidation resistance, no moisture, no fire, easy to deformation, discoloration. At present in the big city PVC has been listed as out of products. With the improvement of the quality requirements of the decoration, and now home decoration has been basically used to do ceiling plate ceiling. Aluminum plate can be fire, moisture, anti-static, sound-absorbing sound insulation, and beautiful and practical, so it is most suitable for the use of more water and kitchen.

- Q:Figure, 600 * 600 or 300 * 300 aluminum buckle plate can not make such a light groove, the edge is not used to close the edge of the edge? Not much, thanks for the answer!

- Side of the edge is no problem, but the aluminum plate to do this, may not be good-looking, there are two main, one is added after the light of the aluminum plate will be bright light, the second is the same as the aluminum plate will reflect the light Tube or a long time gray, ugly.

- Q:What is the balcony ceiling hanging? Lycra board or sauna board? What kind of long life?

- See where you are hanging. The kitchen or the bathroom is the aluminum plate

- Q:The top of the kitchen did not line, like the largest reduction in space, at least how high Is the kitchen

- Then the general situation of such a ceiling distance of 800-1200cm Second, the kitchen, home kitchen, then the ceiling is generally between 300-500cm. Recommended at least not less than 20cm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory Acoustic Perforated Aluminum Ceiling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords