Drilling Rig for Construction of SMWBored Pile Drilling Rig

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

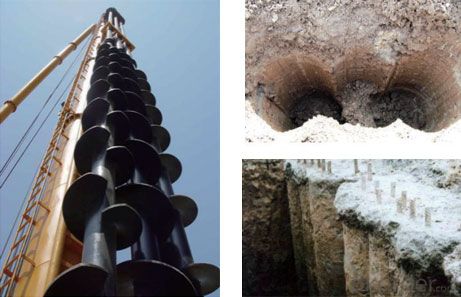

Drilling Rig for Construction of SMWBored Pile Drilling Rig

Product Features:

| SMW, which is short of Soil Mixing Wall, is a construction method developed in Japan in 1976. Now it consists 50% of underground continuous wall constructions in Japan, and widely adopted in countries in southeast Asia, the United States, France etc. In Shanghai, Hangzhou, Nanjing and other cities of China, SMW becomes quite popular after its introduction years ago. SMW uses multi-shaft auger to drill soil in situ, meanwhile pumps cement grout from the tips of the augers into the drilled holes. After sufficient mixing of the grout, H-shaped steel or other types of steel are embedded into the columns before the soil-cement mixture hardened, forming a underground continuous wall with rigidity and intensity. The wall could be used as retaining support or water seal. Three-shaft auger machine is commonly used. |

| SMW method has the following advantages: |

| 1.Low cost. Foundation retaining using SMW method with three-shaft auger machine is much more competitive in price than traditional method when constructing underground continuous wall. 2.Shorter construction period. SMW method consumes much less time than other methods. Under normal geographical conditions, it could build 70-80m² walls per shift. 3.Good seal quality. The wall is continuous without any cracks. Hydraulic conductivity can reach as much as 10-7cm/s. 4.No disturbance in nearby soils. SMW method would not cause hazards like ground subsidence, building inclining, road cracks or shift of underground facilities. 5.Wide range in use. It can be applied on cohesive soil, silt , sandy soil, gravel soil. 6.the waste soil is far less than other construction methods. |

| Name | Unit | Parameters |

|---|---|---|

| Hole dia. | mm | 600 |

| Center distance of rig | mm | 450 |

| Max drilling depth | m | 30 |

| Max output torque | kn·m | 84 |

| Rod rotary speed | r/min | 20 |

| Motor power | kw | 2X75 |

| Total weight | t | 19.8 |

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q:What are the types of pile drivers? What are the characteristics of each?

- This is not clearly defined. It mainly depends on the geological conditions and the superstructure. Who can tell you clearly that it is all Mongolia?.According to the above features you can see, generally divided into two categories, diesel hammer hole, drill hole, Luoyang shovel into the hole is used more, low cost, suitable for Northwest collapsible loess, the pile can eliminate the collapsibility of loess geology, increase the original basis composite bearing capacity. The pipe pile should be chosen according to the address condition, and the construction cost is high. According to the geological difference, sometimes the diesel hammer or drilling machine is needed to carry out the pre boring operation. Rotary drilling drill across the country for a variety of industries (work, the DAB, railways, highways, bridges, etc.), is the best way to operate a single pile.Specific choices are based on geological conditions and superstructure, and geological moisture content is also a key. I am engaged in the foundation construction, any questions contact at any time. Of course, there is a better engineering, ha ha, all kinds of machinery are available, are free equipment, reasonable price appropriate.

- Q:Which price is low for a pile driver?

- Specializing in sales of steel sheet pile, steel sheet pile construction, leasing, model complete, high quality, the construction of steel sheet pile, the price is more favorable, and exquisite design, honest and trustworthy business purposes, in full accordance with the market-oriented, large-scale, standardized operation requirements specification, through the implementation of brand strategy to build the core competitiveness of enterprises

- Q:Is the architecture of the pile driver strong in single core performance or multi - core capability? Or?

- Overall, the AMD's nuclear performance has not been improved for almost 10 years. Basically maintained at the level of K8.

- Q:What are the main types of pile drivers?

- And fuel injection, explosion, shock, ventilation and other work. The work is to rely on diesel hammer compression ignition diesel to start, it is necessary to ensure the cylinder seal The gas reaches a certain compression ratio, sometimes piling in soft soil layer is often because the reaction is too small, the amount of compression is not sufficient to ignite the initiation, you need to use multiple hook lift hammer decoupling impact, to start. The hammer seat diesel hammer with a fuel injection pump, fuel tank, cooling water tank and the pile cap. Play between the piston and the cylinder with elastic piston ring seal.x0d four hydraulic hammer x0d diesel oil to start with, the pressure into motivation, according to different soil hydraulic impact force to achieve the adjustment, the appropriate piling, is a new type of piling machine. Small and medium sized hydraulic piling machine, piling commonly used in the highway guardrail, highway guardrail construction. Similar piling equipment: hydraulic piling machine, highway guardrail, piling machine, piling machine road drill.

- Q:What is a pile driver used for?

- As the name suggests, of course, piling is used, such as building houses, foundations, bridges, foundations and so on. For soft foundation construction site, the design of concrete prefabricated pile or steel pipe pile made of pile, use a pile driver to hit the ground until the design of the formation.

- Q:2. Are they parallel? 3. There is a E3 in the civilian machine was high, but as the server CPU, should be at the bottom of the right?

- A pile driver is an improvement in bulldozers. No leap, but improved performance.

- Q:Track excavator truck model, preferably material, and some are sent to the mailbox thank you very much

- You can get them with the manufacturers who produce them. They usually do. Not really. Just find someone to look at the equipment and draw one.

- Q:Amd pile driver with motherboard, motherboard chipset is 970 or 990fx?

- 990FX prices higher, 970 lower prices.In addition to price factors, attention should also be paid to specifications, such as power supply and so on.

- Q:Do you make money on building pile drivers? How long will it take to recover the cost?

- Can make money, in the case of business, half a year time will be able to recover costs!

- Q:such as bulldozers, pile drivers, cranes and cement mixers?

- Promote。 As for Chinese chopsticks, fork to foreigners, the Xu

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drilling Rig for Construction of SMWBored Pile Drilling Rig

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords