Best Price For Aluzinc Steel EN 10125

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

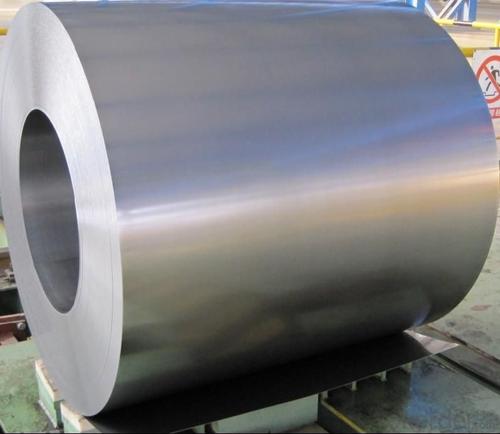

General Information Of Aluzinc Steel EN 10125

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.25-4.0mm (BMT) |

|

Aluzinc Coating 50-150g/m2 |

|

Width 900-1250mm |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Surface Treatment Oiled or Dry, Chromated, Anti-finger,Non-skinpass,/ Skinpass |

|

Standard JIS G 3321, ASTM A792M, EN 10215 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel EN 10125

|

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Aluzinc Steel EN 10125

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out- of-Square |

Not exceed 1% Flatness |

|

Bow |

15mm max |

|

Edge Wave |

9mm max |

|

Centre Buckle |

8mm max |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Aluzinc Steel EN 10125

Aluzinc Steel can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliances.

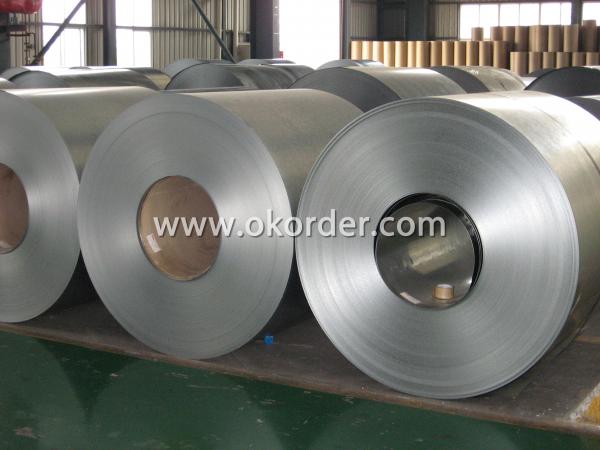

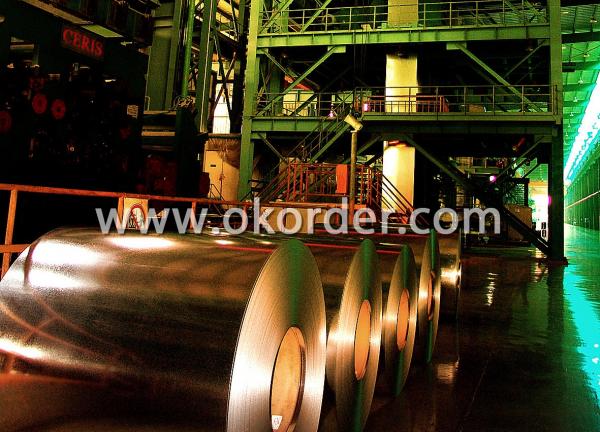

Packaging & Delivery Of Aluzinc Steel EN 10125

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled with iron strips.

- Q:How is steel used in the manufacturing of agricultural machinery?

- Steel is commonly used in the manufacturing of agricultural machinery due to its strength and durability. It provides the necessary structural support and can withstand the harsh conditions often encountered in agricultural settings. Steel components, such as frames, blades, and gears, are utilized in various types of equipment, including tractors, combines, plows, and harvesters, to ensure their reliability and longevity.

- Q:What are the properties of weather-resistant steel?

- Weather-resistant steel, also known as corten steel, possesses several properties that make it ideal for withstanding harsh weather conditions. Firstly, it forms a protective oxide layer on its surface, which acts as a barrier against corrosion and prevents the steel from rusting. Additionally, this steel has high tensile strength, allowing it to withstand strong winds and impacts. It also has good weldability, making it easy to fabricate and work with. Moreover, weather-resistant steel is durable and requires minimal maintenance, making it a cost-effective choice for outdoor structures and buildings.

- Q:How is steel used in the production of automotive parts and components?

- Steel is a crucial material in the production of automotive parts and components due to its strength, durability, and cost-effectiveness. It is commonly used in the manufacturing of car bodies, engine components, chassis, and suspension systems. The steel is shaped and formed into various parts through processes like stamping, welding, and casting, ensuring precision and reliability. Its high tensile strength and ability to withstand extreme conditions make it an ideal choice for ensuring the safety and performance of automotive vehicles.

- Q:How is steel tubing used in the production of furniture?

- Steel tubing is commonly used in the production of furniture to provide structural support and stability. It is often used for the frames of chairs, tables, and other pieces of furniture to ensure durability and longevity. Steel tubing also allows for versatile designs and can be bent or molded into various shapes to meet the desired aesthetic and functional requirements of the furniture.

- Q:What are the uses of steel wire mesh in agriculture?

- Steel wire mesh is commonly used in agriculture for various purposes. It is used as fencing material to create boundaries and protect crops from animals or pests. Steel wire mesh is also used as trellises or support structures for climbing plants, such as tomatoes or beans. Additionally, it can be used to create cages or enclosures for livestock or poultry, providing them with a safe and secure environment. The durability and strength of steel wire mesh make it an ideal material for these applications in agriculture.

- Q:What is the role of steel in the manufacturing of appliances?

- The role of steel in the manufacturing of appliances is crucial as it provides strength, durability, and resistance to heat and corrosion. Steel is used in various components of appliances, such as the outer shells, frames, and internal structures, to ensure they can withstand the rigors of everyday use and maintain their integrity over time. Additionally, steel's malleability allows for the creation of complex shapes and designs, making it a versatile material for appliance manufacturing.

- Q:What are the different types of steel channels?

- There are several different types of steel channels, including C channels, U channels, and J channels. C channels have a distinct shape resembling the letter C and are often used in structural applications. U channels have a shape resembling the letter U and are commonly used for edge protection or as a support beam. J channels have a shape resembling the letter J and are typically used for framing window and door openings.

- Q:What are the different types of steel coatings for corrosion prevention?

- There are several types of steel coatings available for corrosion prevention, including galvanized coatings, metallic coatings, organic coatings, and ceramic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface to provide a protective barrier against corrosion. Metallic coatings, such as aluminum or zinc-aluminum, offer excellent corrosion resistance due to their sacrificial properties. Organic coatings, such as epoxy or polyurethane, create a protective film on the steel surface to prevent contact with corrosive elements. Ceramic coatings, like porcelain enamel or vitreous enamel, offer high resistance to corrosion, chemicals, and extreme temperatures. Each type of coating has its advantages and suitability for specific applications.

- Q:How is steel wire galvanized for wire rope applications?

- Steel wire is galvanized for wire rope applications through a process called hot-dip galvanization. In this process, the steel wire is thoroughly cleaned to remove any impurities and then dipped into a bath of molten zinc at a temperature of around 450 degrees Celsius. The zinc coating bonds to the surface of the steel wire, creating a protective layer that helps prevent corrosion and extends the lifespan of the wire rope.

- Q:What are the different types of steel rails and their applications in tram systems?

- There are several types of steel rails used in tram systems, each with its own specific applications. The most common types include grooved rail, Vignole rail, and flat-bottomed rail. Grooved rail has a groove along its top surface, allowing the tram wheels to fit into it. This type is commonly used in street-level tram systems as it provides better traction and stability, especially during cornering. Vignole rail, also known as T-rail, is characterized by its shape resembling the letter "T". It is commonly used in tram systems that run on dedicated tracks, providing stability and support for the tram wheels. Vignole rail is also suitable for heavier tram vehicles. Flat-bottomed rail, as the name suggests, has a flat bottom with no groove or special shape. This type is often used in tram systems that share tracks with other types of rail vehicles, such as trains or light rail systems. Flat-bottomed rail allows for smooth transitions between different types of rail, minimizing disruptions in the overall transportation network. Overall, the choice of steel rail type depends on factors such as the tram system's design, track characteristics, and the type of rolling stock used. Each type of rail is specifically designed to optimize performance, safety, and efficiency in tram systems.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Price For Aluzinc Steel EN 10125

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords