Layfield Geomembrane

Layfield Geomembrane Related Searches

Landfill Geomembrane Geomembrane Landfill Cooley Geomembrane Atarfil Geomembrane Prefabricated Geomembrane Geomembrane Factory Geomembrane Machine Geocomposite Membrane Liner Geomembrane Geomembrane For Landfill Reinforced Geomembrane Atarfil Geomembranes Geomembrane Company Prefabricated Geomembranes Textured Geomembrane Impervious Geomembrane Geomembrane Thickness Bgm Geomembrane Geomembranes Geomembrane Australia Teranap Geomembrane Firestone Geomembrane Conductive Geomembrane Geomembrane Containment Geomembrane Cover Terram Geotextile Membrane Sotrafa Geomembrane Geomembrane Pond Permeable Geomembrane China GeomembraneLayfield Geomembrane Supplier & Manufacturer from China

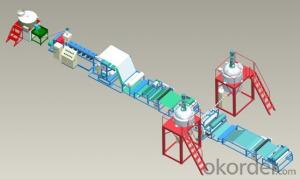

Layfield Geomembrane is a high-quality product that encompasses a range of materials, including HDPE, LDPE, and LLDPE, which are designed to provide excellent water and chemical resistance. These geomembranes are engineered to meet specific project requirements and are widely used in various applications such as landfills, water and wastewater treatment facilities, mining, and environmental containment. The versatility of Layfield Geomembrane makes it an ideal solution for a multitude of industries and applications where water or chemical resistance is a critical factor.Layfield Geomembrane is utilized in various scenarios where the containment and protection of water, chemicals, or other hazardous materials are essential. It is commonly employed in the construction of ponds, reservoirs, and other liquid containment structures, as well as in the lining of canals, tunnels, and landfills. The product's durability and resistance to UV degradation, along with its ability to withstand harsh environmental conditions, make it a preferred choice for long-term projects. Layfield Geomembrane is also recognized for its ease of installation, which can significantly reduce project timelines and associated costs.

Okorder.com is a reputable wholesale supplier of Layfield Geomembrane, boasting a vast inventory that caters to the diverse needs of clients across different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Layfield Geomembrane products they offer meet the highest industry standards. Their extensive stock allows for quick turnaround times and the ability to fulfill large orders, making them a go-to source for businesses and contractors in need of reliable geomembrane solutions.

Hot Products