Firestone Geomembrane

Firestone Geomembrane Related Searches

Firestone Epdm Geomembrane Firestone Geomembrane Epdm Permeable Geomembrane Geomembrane Material Geomembranes Prefabricated Geomembrane Bitumen Geomembrane Megaplast Geomembrane Geomembrane Machine Geomembrane Fabric Plastic Geomembrane Reinforced Geomembrane Wholesale Geomembrane Geomembrane Thickness Fpp Geomembrane China Geomembrane Prefabricated Geomembranes Pe Geomembrane Gse Geomembrane Conductive Geomembrane Landfill Geomembrane Geomembrane Film Geomembrane Containment Geomembrane Properties Geomembrane Technologies Geomembrane Systems Geomembrane Materials Geomembrane Australia Waterproof Geomembrane Geomembrane CompanyFirestone Geomembrane Supplier & Manufacturer from China

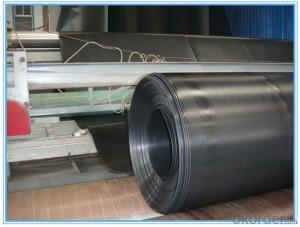

Firestone Geomembrane is a high-quality waterproofing and lining product that is widely used in various industries. These products are designed to provide excellent protection against water infiltration and contamination, making them ideal for applications such as pond liners, landfill liners, and other civil engineering projects. The durability and flexibility of Firestone Geomembrane make it a popular choice for professionals in the construction and environmental sectors.Firestone Geomembrane is utilized in a broad range of applications, including environmental protection, water management, and construction. Its versatility allows it to be used in both residential and commercial settings, such as in the creation of water features, reservoirs, and waste containment facilities. The product's ability to withstand harsh weather conditions and chemical exposure makes it a reliable solution for long-term projects where watertightness is crucial.

Okorder.com is a reputable wholesale supplier of Firestone Geomembrane, offering a vast inventory to meet the demands of various projects. With a commitment to quality and customer satisfaction, Okorder.com ensures that clients receive the best possible products at competitive prices. By partnering with Okorder.com, customers can benefit from their extensive experience and knowledge in the industry, ensuring that they receive the right Firestone Geomembrane solution for their specific needs.

Hot Products