Galvanized Steel Gutters

Galvanized Steel Gutters Related Searches

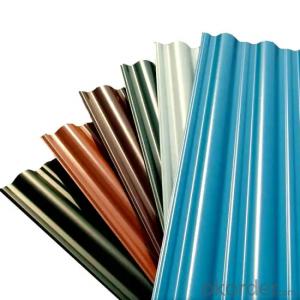

Stainless Steel Gutters Galvanized Steel Grating Galvanized Stainless Steel Galvanized Corrugated Steel Rusting Galvanized Steel Galvanized Steel Pipes Stainless Steel Gutter Guards Stainless Steel Gutter Galvanized Steel Tubs Galvanized Steel Fencing Galvanized Steel Beams Galvanized Tube Steel Galvanized Steel Tank Steel Galvanized Galvanized Steel Planter Galvanized Steel Tube Galvanized Steel Piping Cutting Galvanized Steel Weld Galvanized Steel Galvanized Steel Planters Rusted Galvanized Steel Corrugated Galvanized Steel Galvanized Steel Edging Galvanized Steel Roof Painted Galvanized Steel Galvanized Steel Tub Galvanized Steel Siding Galvanized Steel Square Tubing Stainless Steel Gutter Guard Galvanized Steel PanelsGalvanized Steel Gutters Supplier & Manufacturer from China

Galvanized Steel Gutters are a type of gutter system made from steel that has been coated with a protective layer of zinc to prevent rust and corrosion. This material choice makes them durable and long-lasting, suitable for various types of buildings and architectural styles. They are known for their strength and resistance to harsh weather conditions, making them a popular choice for homeowners and contractors alike.Galvanized steel gutters are widely used in residential and commercial properties due to their ability to handle heavy rainfall and snowmelt effectively. They are installed on the edges of roofs to collect and direct water away from the building's foundation, protecting it from water damage and erosion. These gutters can be found on various types of buildings, from single-family homes to large commercial structures, and are particularly useful in areas with heavy precipitation or where ice dams are a concern.

Okorder.com is a reputable wholesale supplier of Galvanized Steel Gutters, offering a vast inventory to cater to the needs of contractors, builders, and homeowners. They pride themselves on providing high-quality products at competitive prices, ensuring that customers receive the best value for their investment. With a commitment to customer satisfaction, Okorder.com is a trusted source for those in need of reliable and efficient gutter systems.

Hot Products