Aluminum Foil Alternatives

Aluminum Foil Alternatives Related Searches

Alternative To Aluminum Foil Alternative Of Aluminum Foil Aluminum Foil Substitute Substitute Aluminum Foil Substitute For Aluminum Foil Aluminum Foil Replacement Instead Of Aluminum Foil Types Of Aluminum Foil Aluminum Foil Products Aluminum Foil Storage Ideas Buy Aluminum Foil Best Aluminum Foil Reusing Aluminum Foil Aluminum Foil For Packaging Aluminum Foil Converters Cheap Aluminum Foil Reusable Aluminum Foil Decorative Aluminum Foil Aluminum Foil Packs Aluminum Foil Coated Aluminum Paper Foil Aluminum Foil For Shielding Tricks With Aluminum Foil Brands Of Aluminum Foil Aluminum Foil Foam Aluminum Foil Leaves Aluminum Foil Tricks Aluminum Foil For Walls Foil Aluminum Foam With Aluminum FoilAluminum Foil Alternatives Supplier & Manufacturer from China

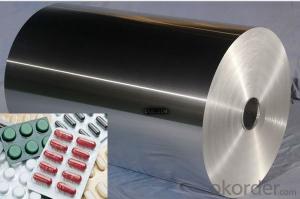

Aluminum foil alternatives are a range of products designed to replace traditional aluminum foil in various applications, offering eco-friendly and convenient solutions. These alternatives include products such as reusable silicone food covers, beeswax wraps, and parchment paper, which can be used for food storage, cooking, and baking. They are particularly useful in scenarios where aluminum foil may not be the most suitable choice, such as when cooking with acidic or high-sodium foods, or when seeking a more sustainable option for food preservation.Okorder.com is a leading wholesale supplier of aluminum foil alternatives, boasting a vast inventory that caters to the diverse needs of customers. With a commitment to providing high-quality products, Okorder.com ensures that their aluminum foil alternatives are made from safe, non-toxic materials and are designed to be durable and long-lasting. This makes them an excellent choice for both commercial and household use, as they can be easily cleaned and reused multiple times, reducing waste and promoting a more sustainable lifestyle.