Instead Of Aluminum Foil

Instead Of Aluminum Foil Related Searches

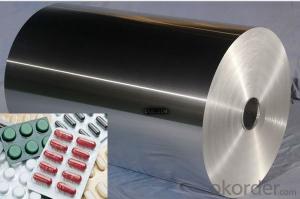

Alternative Of Aluminum Foil Alternative To Aluminum Foil Substitute For Aluminum Foil Substitute Aluminum Foil Aluminum Foil Substitute Aluminum Foil Alternatives Aluminum Foil Replacement Aluminum Or Tin Foil Foam With Aluminum Foil Tin Foil Or Aluminum Foil Wrapped In Aluminum Foil Shielding With Aluminum Foil Tin Or Aluminum Foil Wrapping With Aluminum Foil Reusing Aluminum Foil Aluminum Foil Non Stick Buy Aluminum Foil Box Of Aluminum Foil Tin Foil And Aluminum Foil Cheap Aluminum Foil Recycled Aluminum Foil Bare Aluminum Foil The Aluminum Foil Trick Two Sides Of Aluminum Foil Ate Aluminum Foil Paint With Aluminum Foil Fear Of Aluminum Foil Aluminum Foil Coated Aluminum Foil As Insulation Printed Aluminum FoilInstead Of Aluminum Foil Supplier & Manufacturer from China

Instead of Aluminum Foil, we offer a range of eco-friendly and reusable alternatives that are perfect for food storage, cooking, and baking. These products are designed to reduce waste and provide a healthier option compared to traditional aluminum foil. Our alternatives include silicone baking mats, reusable food wraps, and parchment paper, which can be used in various kitchen applications, from wrapping leftovers to lining baking sheets. These products are not only environmentally friendly but also versatile, making them a popular choice for both home cooks and professional chefs. Okorder.com is a leading wholesale supplier of Instead of Aluminum Foil products, boasting a large inventory to cater to the growing demand for sustainable kitchen solutions. Our extensive range ensures that customers can find the perfect alternative to aluminum foil for their specific needs, all available at competitive prices and with the convenience of bulk purchasing options.Hot Products