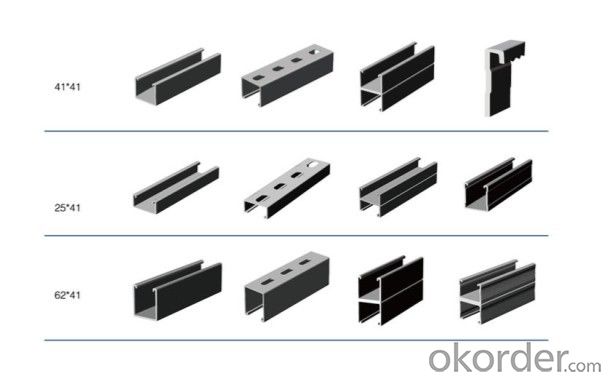

ZYTF PRE-PAINTED ALUZINC STEEL galvanized H type steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

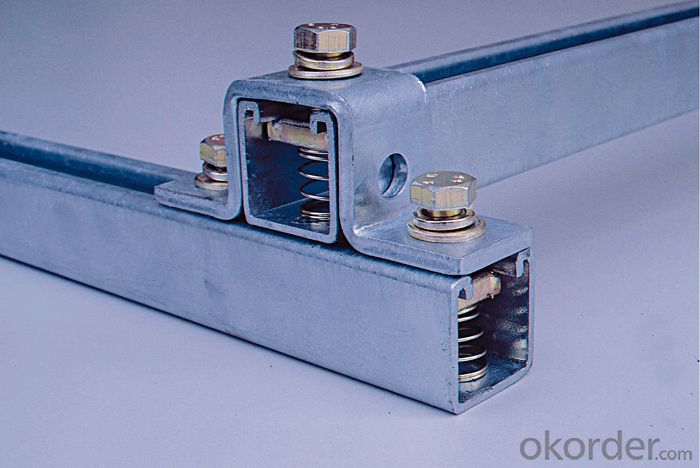

No welding and drilling. Can be conveniently Cagai adjustment, repeated use, wasteminimization.

The professional good coordination, improve indoor space elevation

Has good compatibility, the professional can share a hanger; make full use of space, can make each professional bundles can be good coordination.

- force, stable and reliable

Design and construction of atlas and complete, all the stress components -- type steel and fastener (with locking serrations) can realize the assembly components of a rigid mating,connecting without displacement, no order adjustment, accurate positioning. Shock and vibration, enhance the shear resistance capacity of bracket nodes.

And tracking services, real-time guidance, doubts on the construction site

Technical personnel at the scene guidance, FAQ, do mechanics analysis in real-time tomeet in the construction of the special support and hanger, and the coordination of various professional bundle

And fast installation, short construction period

The installation speed is 6~8 times of traditional practices, in reducing the cost ofmanufacture and installation of 1/2. All professions and trades cross operation, improve work efficiency, shorten the construction period.

And long service life, convenient maintenance

The use of the environment, according to special requirements of customers, provide different process materials are electric galvanized (Leng Duxin), hot dip galvanized andgalvanized coating powder (spray)

Quasi - materials budget

Ensure the products for the standardization of semi-finished products, model identificationwith clear, standardized management, materials and the fittings on the waste and loss ofrare.

And excellent quality assurance

With ISO9000, ISO9002 standard, ensure the stability of the whole system integrity andhanger.

Good generality

And the combination of standard component types of rich, available options. Ensure all kinds of support under different conditions, simplicity, applicability and flexibility.

And environmental protection

Construction without welding and flame, will not impact on the environment and office.

Our factory has ten fully automatic and semi automatic cold bending production line eight,has its own development team, the independent development of mold design to meet the various needs of customers. Product appearance, size precision, reasonable design,convenient use saves the massive manpower and physical for customers, reducing the cost, the products are widely used in the construction industry, automobile manufacturing,solar power generation, machinery manufacturing, power transmission tower, bridge, shipmilitary aviation industry, railway and highway construction, machine room equipmentcontainer, mineral support etc.. The best-selling products, well received by customers. This is a company won the trust of customers, has broad prospects for development of theenterprise.

Z type steel main points: equilateral Z type steel, galvanized Z type steel, solar stent type Zsteel, the major and medium small type Z steel, Z shaped steel purlin, template supportoverlapped Z type steel Z steel, Z steel, such as automobile profiles, the above specifications for factory main products, such as shape, specifications, drawings can betransfer to my company.

Specifications of Z steel can be used: (26-400) X (25-200) X (9-20) X (0.5-16)

Bottom width X high side X small side wall thickness of X = can be customized

- Q: How are steel structures designed to accommodate for differential settlement?

- Steel structures are designed to accommodate for differential settlement by using flexible connections and adjustable supports. These design features allow the steel components to move independently and adjust their positions, reducing the impact of differential settlement on the overall structure. Additionally, engineers may also incorporate additional measures such as flexible joints or expansion joints to further mitigate the effects of differential settlement on steel structures.

- Q: What are the different types of steel connections used in structures?

- There are several types of steel connections used in structures, including welded connections, bolted connections, riveted connections, and pinned connections. Each type has its own advantages and is chosen based on factors such as load requirements, ease of installation, and structural stability.

- Q: What are the steps involved in the construction of a steel structure?

- The steps involved in the construction of a steel structure typically include site preparation, foundation design and construction, steel fabrication, erection, and finishing works. Site preparation involves clearing the area, leveling the ground, and ensuring proper drainage. Foundation design and construction involve determining the type of foundation required, such as shallow or deep foundations, and then constructing it accordingly. Steel fabrication includes the manufacturing of steel components, such as beams, columns, and trusses, as per the project specifications. Erection involves the assembly and placement of these fabricated steel elements on the foundation, often with the use of cranes and other heavy equipment. Finally, finishing works like insulation, cladding, and interior fittings are done to complete the steel structure.

- Q: How are steel structures used in sports and recreational facilities?

- Steel structures are commonly used in sports and recreational facilities due to their durability, strength, and versatility. They provide a cost-effective solution for constructing large open spaces such as stadiums, arenas, and indoor sports facilities. Steel frames can support the weight of heavy equipment, withstand extreme weather conditions, and allow for flexible design configurations. Additionally, steel structures offer the ability to create large spans without the need for excessive columns, providing unobstructed views for spectators and maximizing usable space within the facility.

- Q: What are the common design considerations for steel mezzanine floors?

- There are several common design considerations for steel mezzanine floors that need to be taken into account in order to ensure their structural integrity and functionality. Firstly, it is important to consider the load capacity of the mezzanine floor. This includes both the dead load, which is the weight of the structure itself, and the live load, which is the weight of the people, equipment, and materials that will be placed on the floor. The mezzanine floor should be designed to support these loads without excessive deflection or deformation. Secondly, the overall height and clear span of the mezzanine should be considered. The height of the mezzanine should be sufficient to allow for the intended use of the space below. Additionally, the clear span, or the distance between the supporting columns, should be optimized to minimize the number of columns required and maximize the usable space. Another important consideration is the fire resistance of the mezzanine floor. Steel is a combustible material, so measures should be taken to enhance the fire resistance of the structure. This can include using fire-resistant coatings or installing fire-rated ceiling tiles or sprinkler systems. The design of the staircases or access points to the mezzanine floor is also a crucial consideration. The stairs should be designed to provide safe and easy access, taking into account factors such as the number of steps, the width of the staircase, handrail heights, and any local building code requirements. Furthermore, the integration of utilities and services should be considered in the design process. This includes electrical, plumbing, and HVAC systems, which may need to be incorporated into the mezzanine floor design. Proper planning and coordination with these services will ensure that they can be easily installed and maintained. Lastly, the aesthetics of the mezzanine floor should also be considered. This includes the choice of finishes and coatings, as well as the overall appearance of the structure. These design elements can help create a visually appealing and functional space. In conclusion, the design considerations for steel mezzanine floors include load capacity, height and clear span, fire resistance, access points, integration of utilities, and aesthetics. By addressing these factors during the design process, a steel mezzanine floor can be efficiently and effectively designed to meet the specific requirements of the space.

- Q: What is the role of steel in bridge construction?

- Steel plays a crucial role in bridge construction as it provides strength, durability, and flexibility. It is used to create the main structural elements of the bridge, such as beams, girders, and trusses, which can withstand heavy loads and span long distances. Steel's high tensile strength allows for the creation of lighter and more efficient bridge designs, while its resistance to corrosion ensures the longevity of the structure. Additionally, steel's ability to be fabricated off-site and easily assembled on-site makes it a preferred material for constructing bridges efficiently. Overall, steel is essential in bridge construction for ensuring the safety, reliability, and longevity of these vital transportation structures.

- Q: How do steel structures compare to concrete structures in terms of cost?

- Steel structures generally tend to be more expensive upfront compared to concrete structures. However, steel offers numerous benefits such as faster construction time, flexibility in design, and higher durability, which can result in long-term cost savings. Additionally, steel structures have a longer lifespan and require less maintenance, ultimately making them a cost-effective option over the building's lifespan.

- Q: How are steel structures designed for loading docks?

- Steel structures for loading docks are designed with careful consideration of the specific loading requirements. This involves analyzing the expected loads, such as the weight of trucks, forklifts, and cargo, and designing the structure to withstand these loads without deformation or failure. Factors such as the size and spacing of beams, columns, and connections, as well as the selection of appropriate materials and reinforcement, are all taken into account to ensure the safety and durability of the loading dock structure.

- Q: What does the steel structure lug 2-240*290*12 mean?

- Steel structure connecting lug 2-240*290*12 means 2 pieces, steel plate of thickness 12MM, length 290MM, width 240MM.Steel structure is mainly made of steel material, and it is one of the main types of building structure. The structure is mainly composed of steel beams and steel plates, such as steel beams, steel columns, steel trusses and so on. Each component or component is usually connected with welds, bolts or rivets. Because of its light weight and simple construction, it is widely used in large factories, stadiums, super high-rise and other fields.

- Q: What is the role of steel in dams and water infrastructure?

- Steel plays a crucial role in dams and water infrastructure as it provides strength, durability, and versatility. It is commonly used in the construction of dam structures, including the main body, spillways, gates, and penstocks, due to its high tensile strength and ability to withstand water pressure. Steel reinforcement is also used in concrete structures to enhance their strength and prevent cracking. Additionally, steel pipes are utilized for water distribution and storage systems, ensuring efficient and reliable water supply. Overall, steel is essential for the stability, longevity, and functionality of dams and water infrastructure.

Send your message to us

ZYTF PRE-PAINTED ALUZINC STEEL galvanized H type steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords